Optimally-designed test fixture for power module

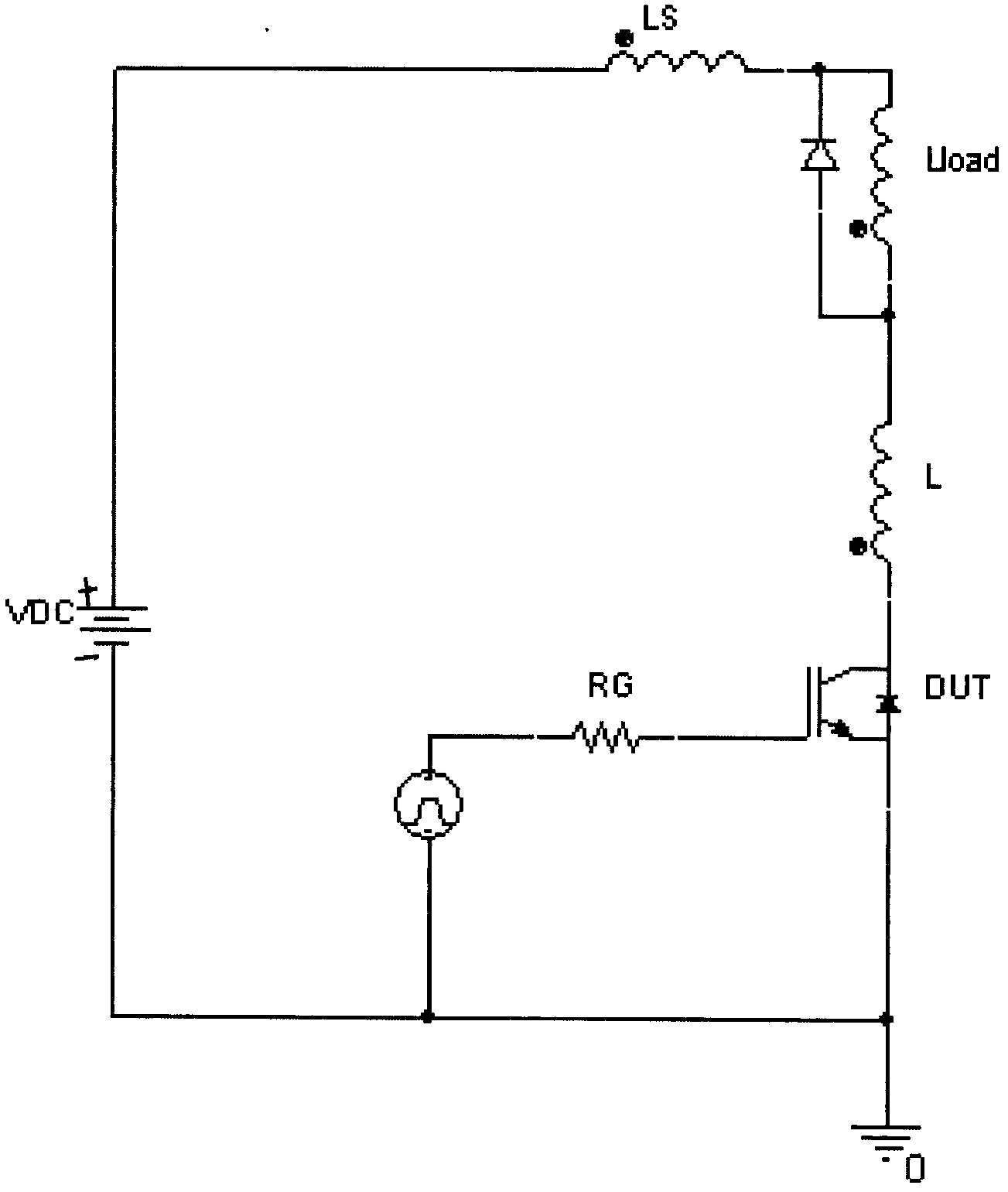

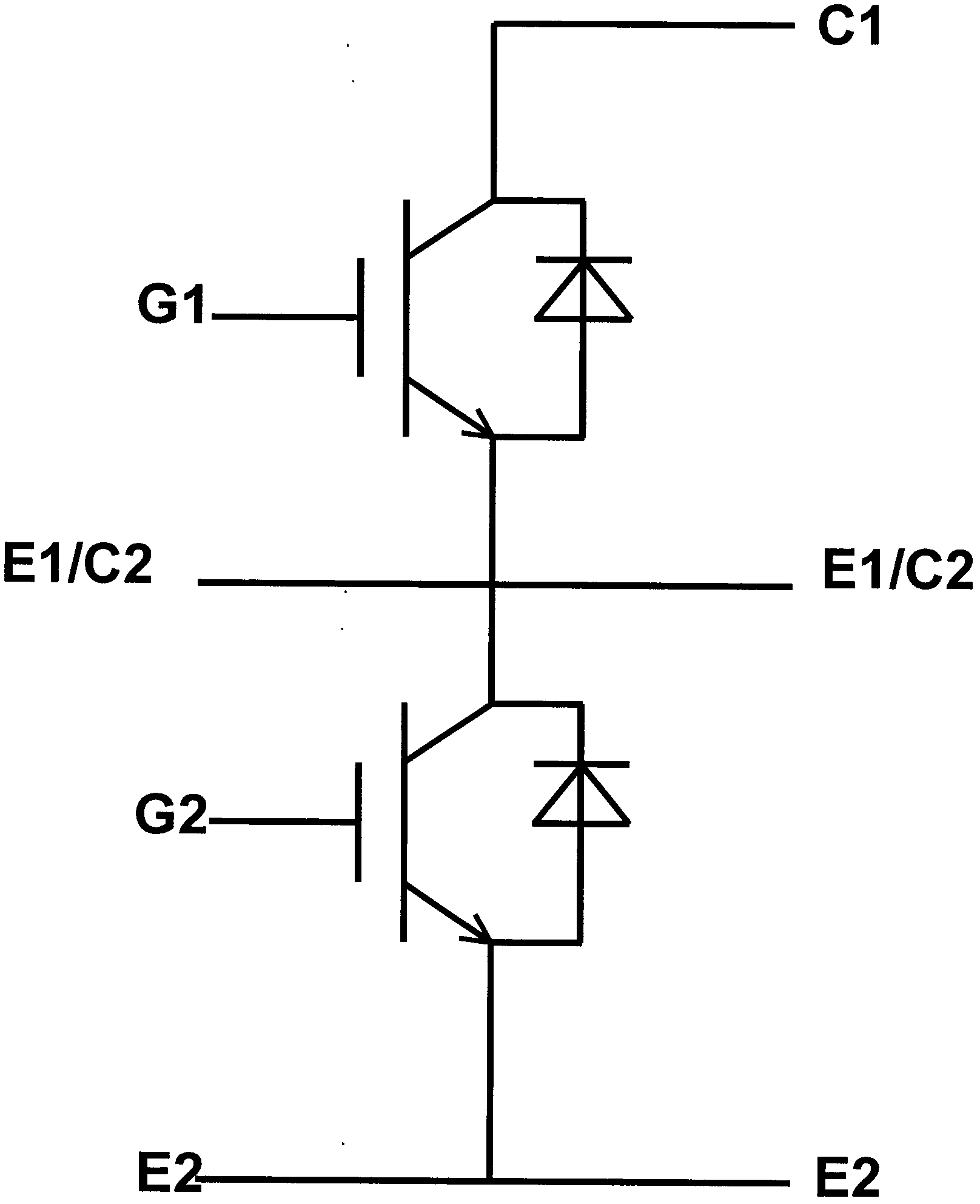

A power module and test fixture technology, which is applied in the direction of measuring electricity, measuring devices, and measuring electrical variables, can solve the problems of test fixture influence and damage to the device under test, so as to improve reliability and accuracy, absorb voltage overshoot, The effect of reducing the probability of voltage breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

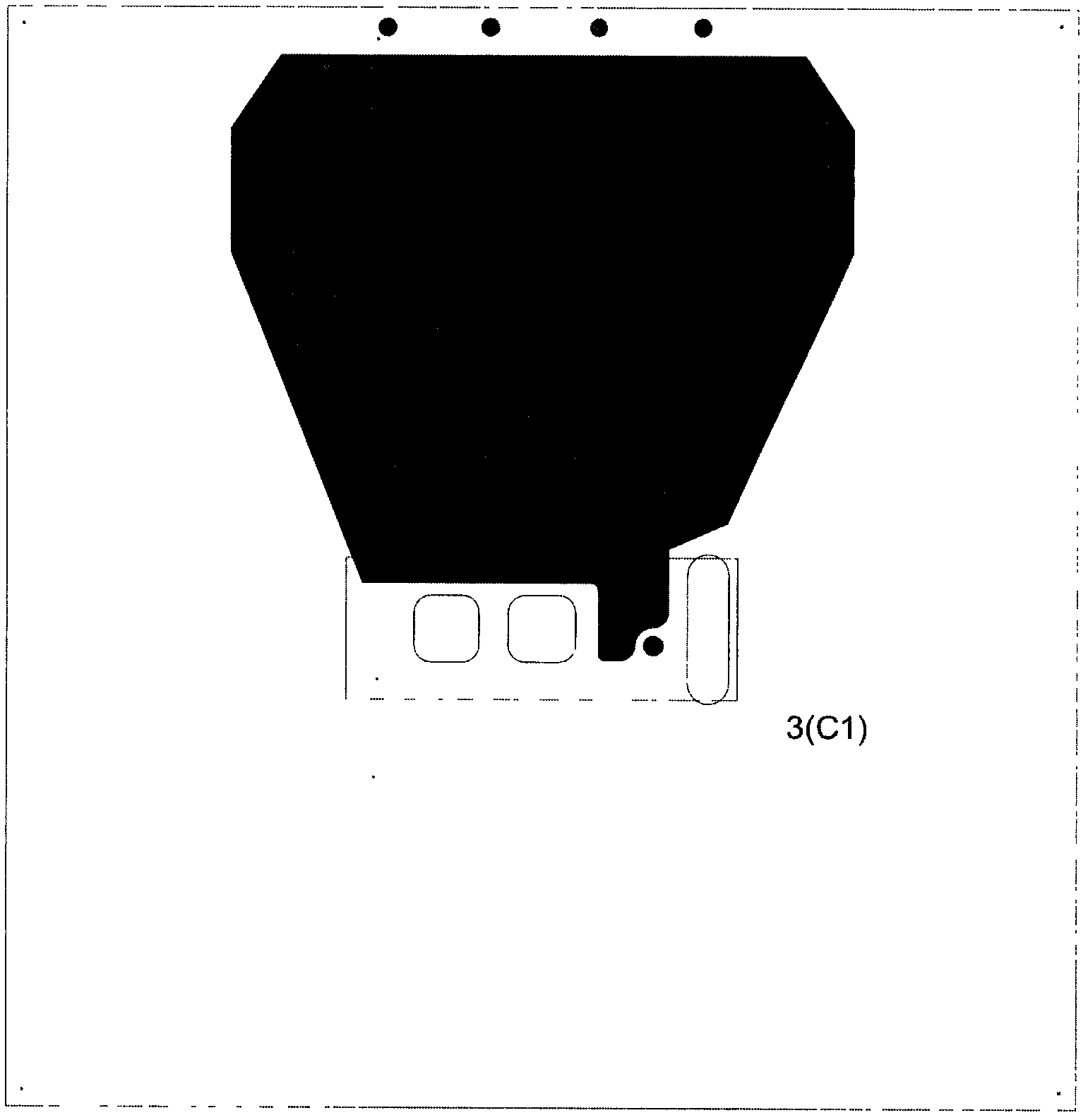

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] As shown in the figure, the present invention includes a substrate 3, a high-current probe 2 and a power circuit 4, a power connection plug 5 is provided on the side of the substrate 3, a signal terminal 6 is provided on the back of the substrate 3, and the high-current probe 2 is arranged on On the front side of the substrate 3, a laminated busbar is fixed on the substrate 3, and a power circuit 4 is etched on the laminated busbar.

[0023] The substrate 3 is made of materials with high strength and good insulation. Such as FR4 material with a thickness of 10mm. Ensure good mechanical strength and insulation performance of the mechanical support.

[0024] The high-current probe 2 is connected to the stacked bus bar. The power connection plug 5 is brazed on the stacked bus bar, and the signal terminal 6 is welded on the probe contact assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com