Building method for electric drive system hardware-in-the-loop simulation device

A technology of electric drive and system hardware, applied in the field of hardware-in-the-loop real-time simulation, which can solve the problems of low real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

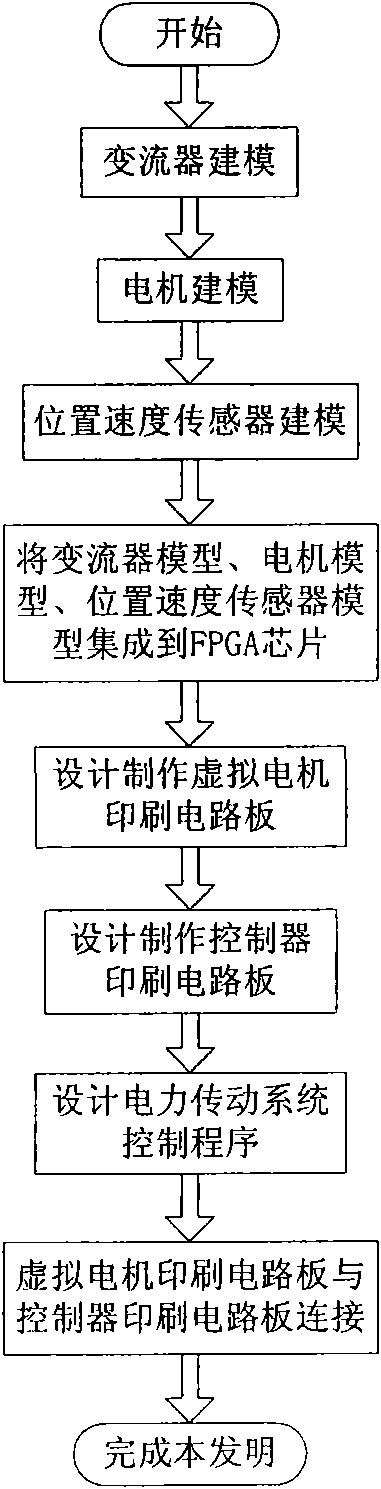

[0068] refer to figure 1 , the construction method of the hardware-in-the-loop simulation device of the electric drive system is: use the hardware description language VerilogHDL to model the converter, motor and position speed sensor in the electric drive system, and then integrate them into an FPGA chip. The FPGA chip used is produced by Altera Corporation of the United States, and the model is EP3C40Q240C8N. The FPGA chip and the interface circuit form a virtual motor printed circuit board, and the virtual motor printed circuit board is connected with the electric drive system controller printed circuit board to form a hardware-in-the-loop simulation device for the electric drive system. The DSP chip used by the power transmission system controller is produced by American TI Company, the model is TMS320F2812. The specific implementation steps are:

[0069] (1) Using the hardware description language Verilog HDL to model the converter in the electric drive system.

[007...

Embodiment 2

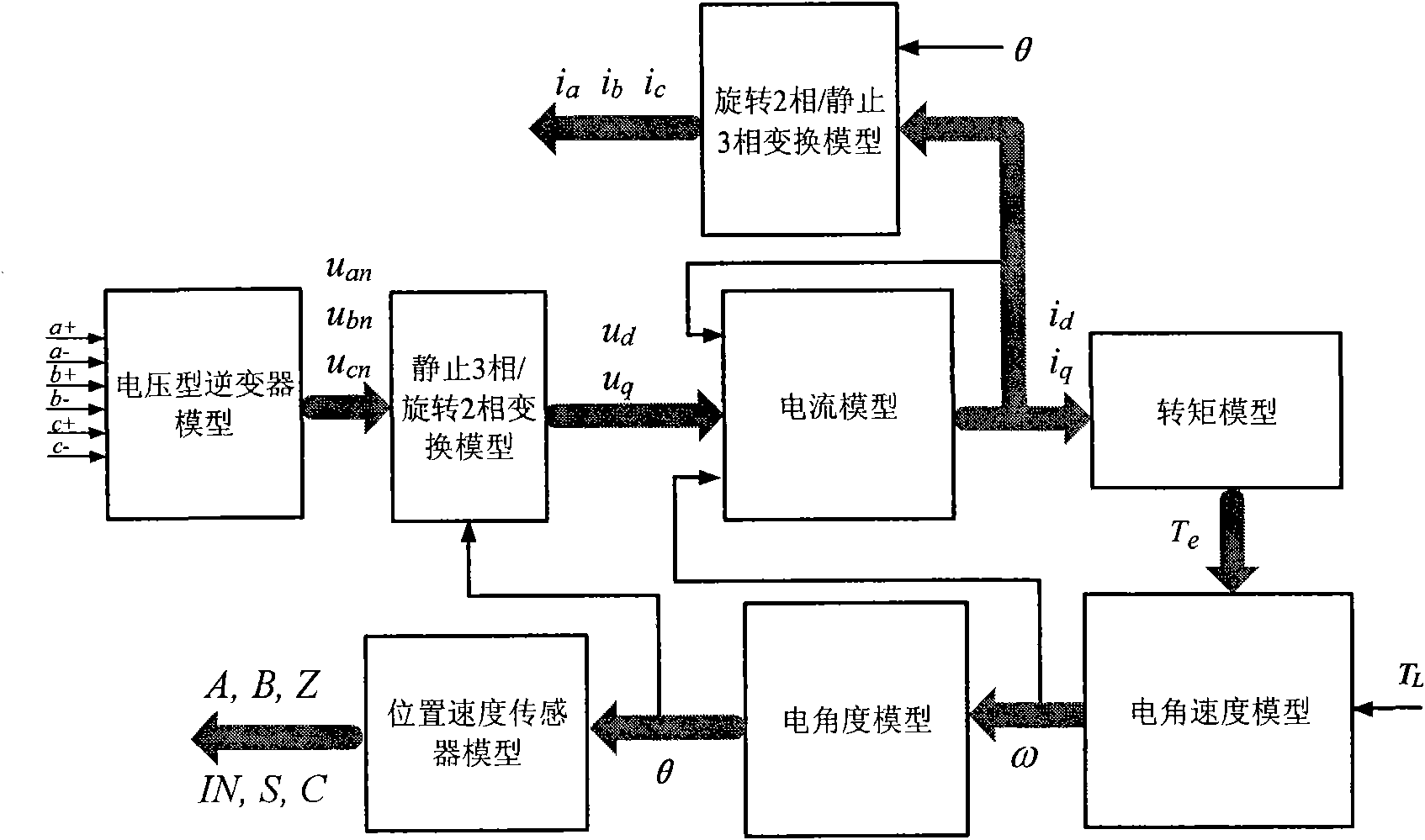

[0078] This embodiment is basically the same as Embodiment 1, and the special features are as follows: Reference figure 2 , the converter model is: receiving six PWM signals a + , a - , b + , b - , c + , c - , calculate the three-phase phase voltage u of the motor by the following formula an , u bn , u cn .

[0079] u an = u dc 6 [ 2 ( a + - a - ) - ( b + - b - ) - ( c + - c - ) ]

[0080] u bn = u d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com