Method for reducing carbon monoxide release amount of papermaking reconstituted tobacco

A technology for reconstituting tobacco leaves and carbon monoxide, applied in the directions of tobacco, tobacco preparation, application, etc., can solve the problems of difficult promotion and application, high cost, and achieve the effects of simple implementation, low cost, and reduced carbon monoxide release.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

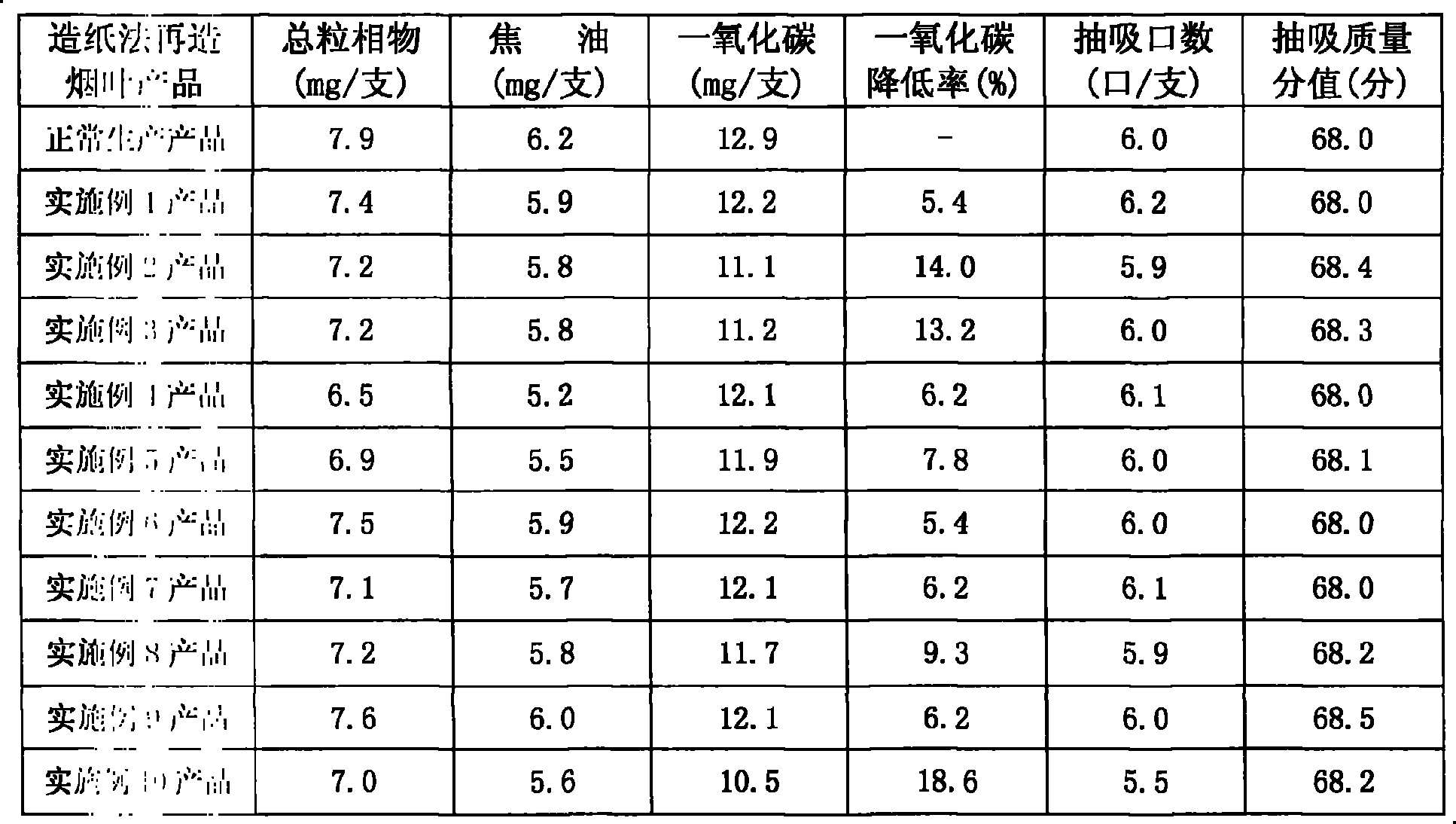

Embodiment 1

[0016] In the coating process of reconstituted tobacco leaf production by papermaking method, 2Kg Li 2 SO 4 The coating material liquid is evenly coated on the reconstituted tobacco leaf base according to the normal production mode and finally processed into 200Kg papermaking method reconstituted tobacco leaf products.

Embodiment 2

[0018] In the coating process of reconstituted tobacco leaf production by papermaking method, 2Kg Na 2 SO 4 The coating material liquid is evenly coated on the reconstituted tobacco leaf base according to the normal production mode and finally processed into 200Kg papermaking method reconstituted tobacco leaf products.

Embodiment 3

[0020] In the coating process of reconstituted tobacco leaf production by papermaking method, 2Kg K 2 SO 4 The coating material liquid is evenly coated on the reconstituted tobacco leaf base according to the normal production mode and finally processed into 200Kg papermaking method reconstituted tobacco leaf products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com