Medium-speed wire cutting method based on high-speed wire cutting machine tool

A cutting method and wire technology, applied in the field of mold processing equipment, can solve the problems of impurities sticking to pulleys and guide rails, rough workpiece processing, etc., and achieve the effects of reducing surface roughness, improving processing accuracy, and improving cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

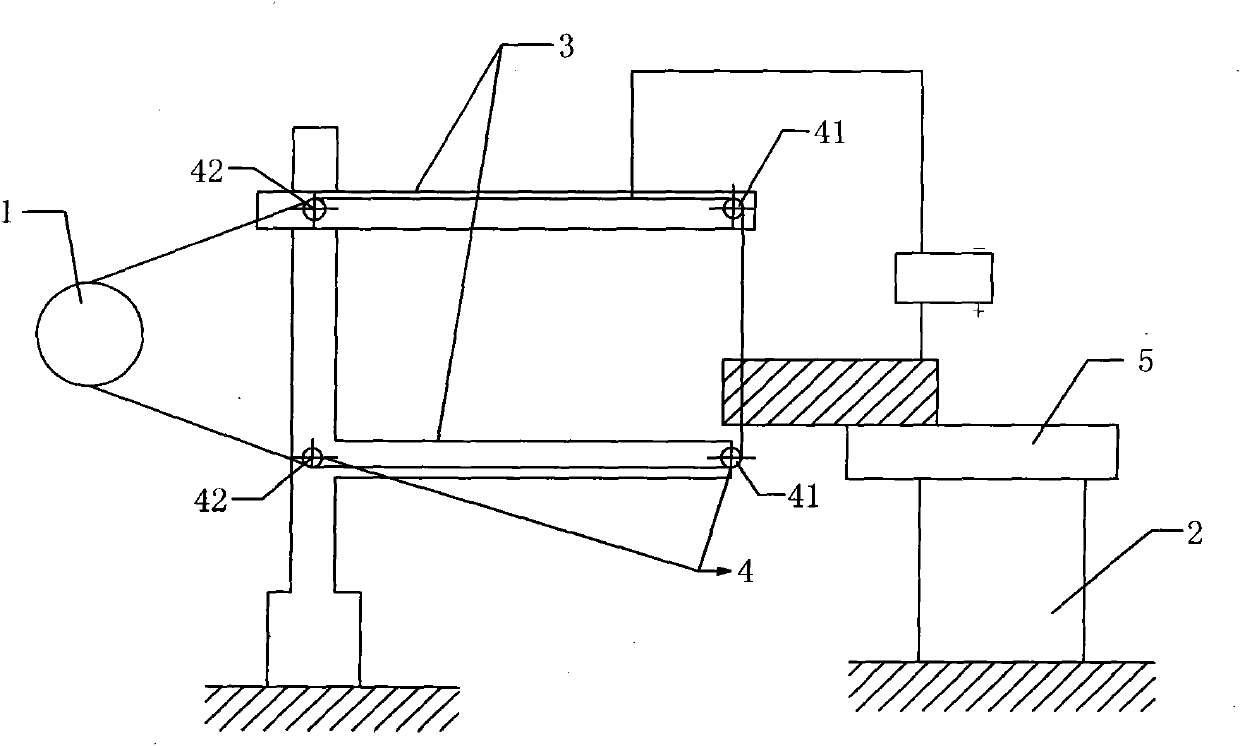

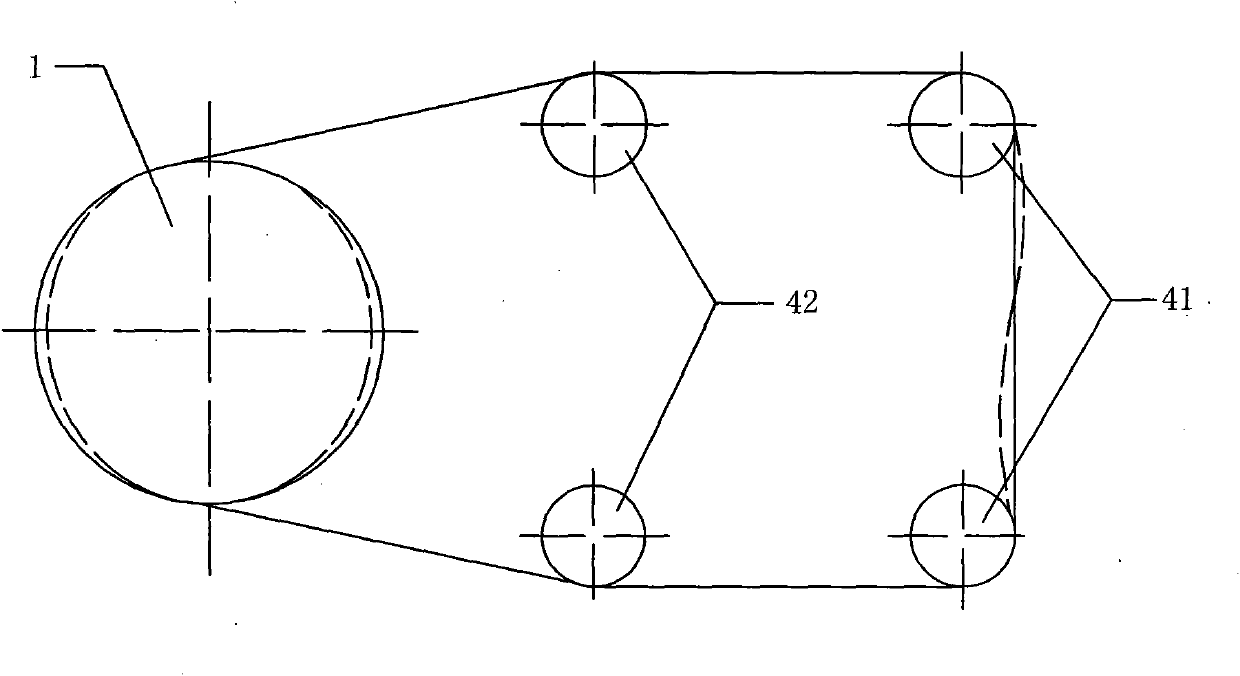

[0036] figure 1 , figure 2 , image 3 and Figure 4 Constitute the specific embodiment 1 of the present invention.

[0037] refer to figure 1 , the present embodiment takes the DK7732 fast-feeding wire-cutting machine tool of Taizhou Dongfang CNC Machine Tool Factory as a carrier, and transforms this machine tool into a middle-feeding wire-cutting machine tool. Through the transformation of machine tool components such as wire storage barrel 1, bed 2, upper and lower cantilever 3, and guide wheel 4, the effect of improving cutting precision and reducing the roughness of the cutting surface is achieved, specifically including the following steps:

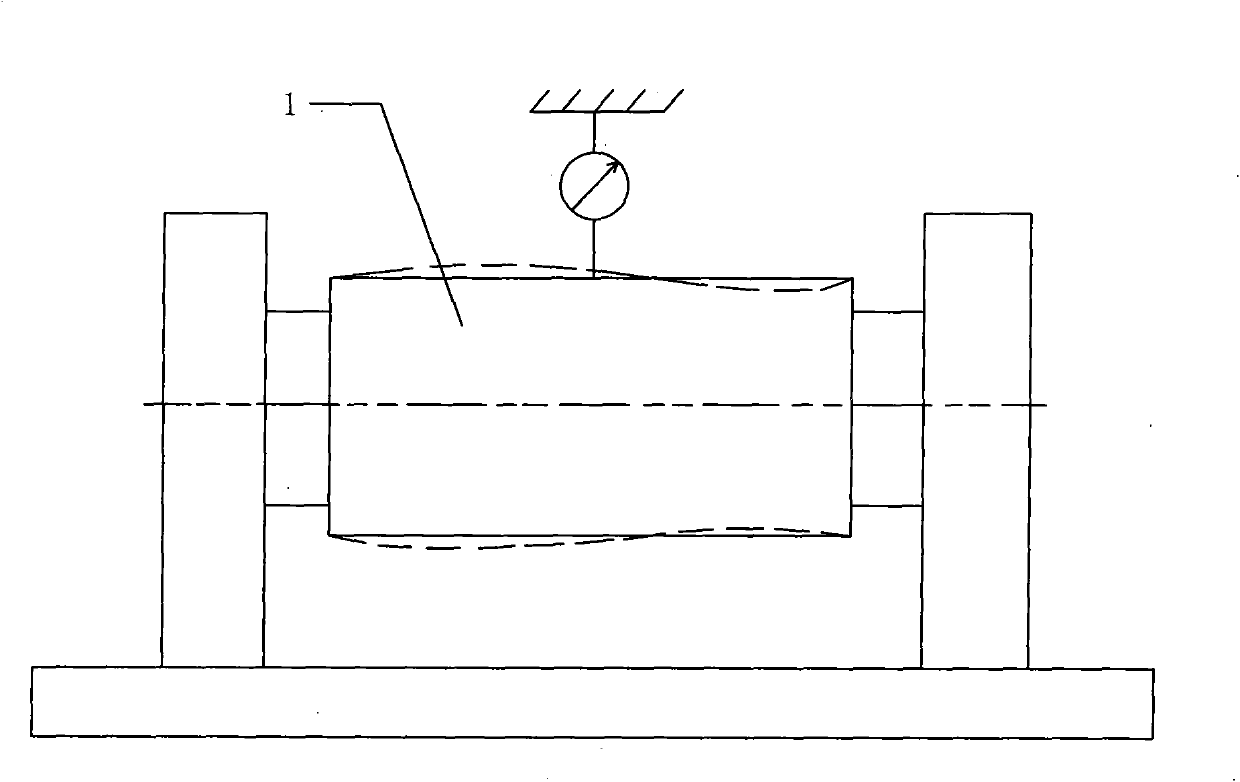

[0038] 1) Repair the roundness, cylindricity and straightness of the busbar of the wire storage drum 1

[0039] refer to figure 2 , the dotted line shown is the roundness of the original fast-feeding wire-cutting machine tool. The roundness tolerance is 0.015-0.02mm, which will cause the wire to vibrate. After the wire storag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Straightness | aaaaa | aaaaa |

| Verticality | aaaaa | aaaaa |

| Roundness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com