Sinter cooler lump ore braking system

A cooling machine and sintering technology, applied in the metallurgical field, can solve the problems of low screening efficiency, large time span, easy dew and sticky dust, etc., and achieve a simple, reliable and practical system, improved screening efficiency, and easy interlock control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

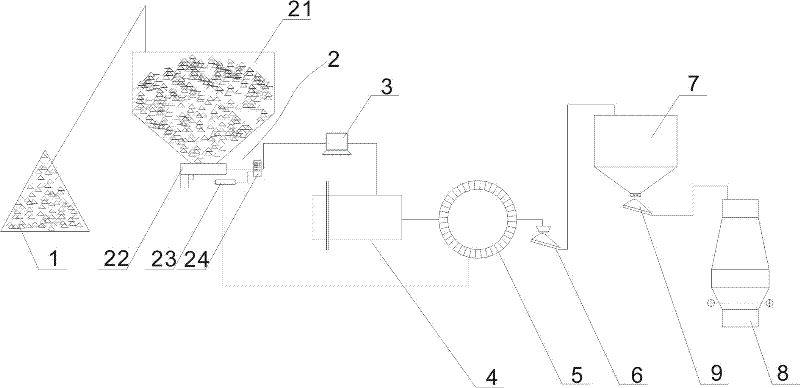

[0017] Such as figure 1 As shown, it consists of lump ore stockpile 1, lump ore proportioning device 2, computer 3, sintering machine 4, ring cooler 5, cold ore screen 6, blast furnace elevated bin 7, and blast furnace 8 in sequence. , described lump ore proportioning device 2 comprises lump ore upper hopper 21, lump ore quantitative feeding device 22, lump ore metering device 23, lump ore metering control cabinet 24, lump ore quantitative feeding device 22 is arranged on Below the discharge port of the lump ore upper silo 21, the lump ore metering device 23 is arranged below the lump ore quantitative feeding device 22, and the lump ore quantitative feeding device 22, the lump ore metering device 23 and the sintering machine 4 are respectively connected with the lump ore metering device. The control cabinet 24 is connected, and the lump ore metering device 23 is also connected with the annular cooler 5; a vibrating screen 9 is arranged between the blast furnace elevated bunker...

Embodiment 2

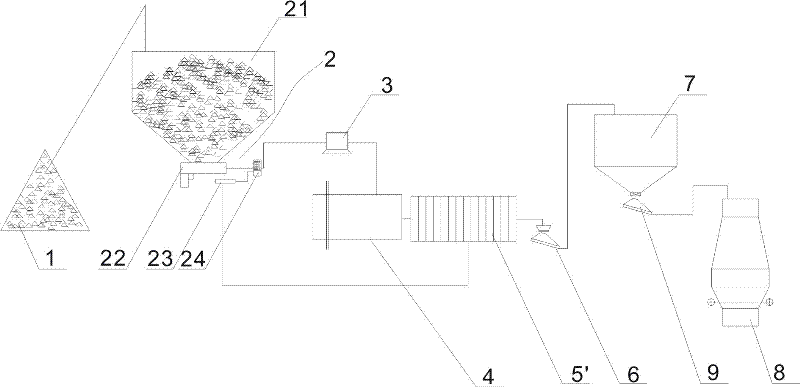

[0020] Such as figure 2 As shown, the annular cooler 5 in Embodiment 1 is replaced by a strip cooler 5', and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com