Conductive core-sheath compound fibre and preparation method thereof

A composite fiber and manufacturing method technology, applied in the direction of fiber processing, fiber chemical characteristics, conjugated synthetic polymer man-made filaments, etc., can solve the problems of easy falling off of carbon black, poor hand feeling, and difficulty in uniform distribution of carbon black.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] In this embodiment, the core layer is polyethylene terephthalate PET, the skin layer is a tin-bismuth metal alloy, and the weight ratio of tin:bismuth is 70:30.

[0079] (a) The weight ratio of the skin layer component to the core layer component is 13:87,

[0080] (b) 1.5 ≤ fineness (dtex) ≤ 20,

[0081] (c) 1.8≤breaking strength (cN / dtex)≤4.5,

[0082] (d) 10≤ breaking elongation (%)≤100,

[0083] (e) The volume specific resistance of the fiber is 1.0×10 -5 ~1.0×10 3 Ω·cm,

[0084] (f) The fiber surface coverage rate of the leather component is ≥90%,

[0085] (g) The shrinkage rate in hot water at 100°C is ≤15%.

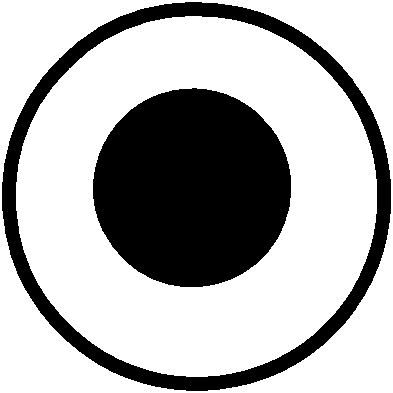

[0086] The cross-sectional shape of the fiber is figure 1 Shown.

[0087] The manufacturing method of this embodiment adopts a composite extrusion method. The raw materials of the above-mentioned skin-core components are respectively processed into a melt through an electric heating furnace and a screw extruder. The melting temperature of the skin material is 149~186℃, ...

Embodiment 2

[0090] In this embodiment, the core layer is PPS, and the skin layer is bismuth metal.

[0091] (a) The weight ratio of the skin layer component to the core layer component is 18:82,

[0092] (b) 1.5 ≤ fineness (dtex) ≤ 20,

[0093] (c) 1.8≤breaking strength (cN / dtex)≤4.5,

[0094] (d) 10≤ breaking elongation (%)≤100,

[0095] (e) The volume specific resistance of the fiber is 1.0×10 -5 ~1.0×10 3 Ω·cm,

[0096] (f) The fiber surface coverage rate of the leather component is ≥90%,

[0097] (g) The shrinkage rate in hot water at 100°C is ≤15%.

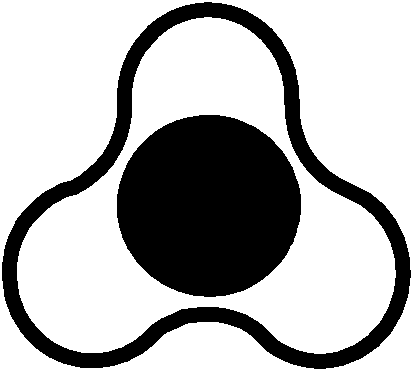

[0098] The cross-sectional shape of the fiber is figure 2 Shown.

[0099] The manufacturing method of this embodiment adopts a composite extrusion method. According to the above-mentioned skin-core components, the raw materials are processed into a melt through an electric heating furnace and a screw extruder. The melting temperature of the skin material is 270~290℃, and the melting temperature of the core material is 330~350℃ . Then they are tran...

Embodiment 3

[0102] In this embodiment, the core layer is nylon 66, and the skin layer is tin metal.

[0103] (a) The weight ratio of the skin layer component to the core layer component is 75:25,

[0104] (b) 1.5 ≤ fineness (dtex) ≤ 20,

[0105] (c) 1.8≤breaking strength (cN / dtex)≤4.5,

[0106] (d) 10≤ breaking elongation (%)≤100,

[0107] (e) The volume specific resistance of the fiber is 1.0×10 -5 ~1.0×10 3 Ω·cm,

[0108] (f) The fiber surface coverage rate of the leather component is ≥90%,

[0109] (g) The shrinkage rate in hot water at 100°C is ≤15%.

[0110] The cross-sectional shape of the fiber is figure 1 Shown.

[0111] The manufacturing method of this embodiment adopts a composite extrusion method. The raw materials according to the above-mentioned skin and core components are respectively processed into a melt through an electric heating furnace and a screw extruder, wherein the melting temperature of the skin material is 230-250°C, and the melting temperature of the core material is 280-3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com