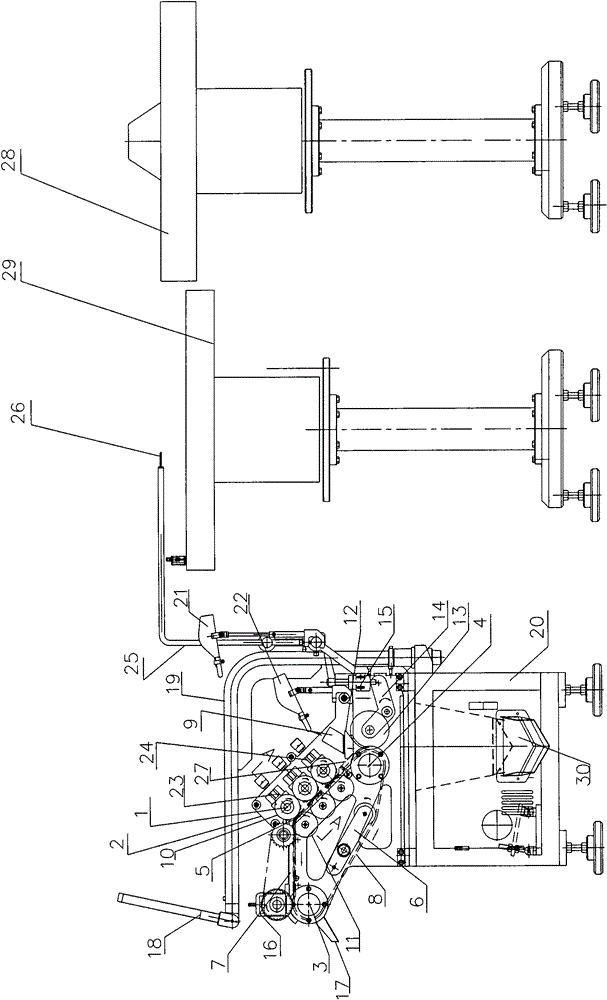

Transverse plastic-sealed diode lead wire straightening machine

A lead-out wire and diode technology, applied in the field of straightening machines for lead-out wires in plastic-encapsulated diodes, can solve the problems of low intelligence, large belt loss, and low production efficiency, achieve high product qualification rate, reduce maintenance costs, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

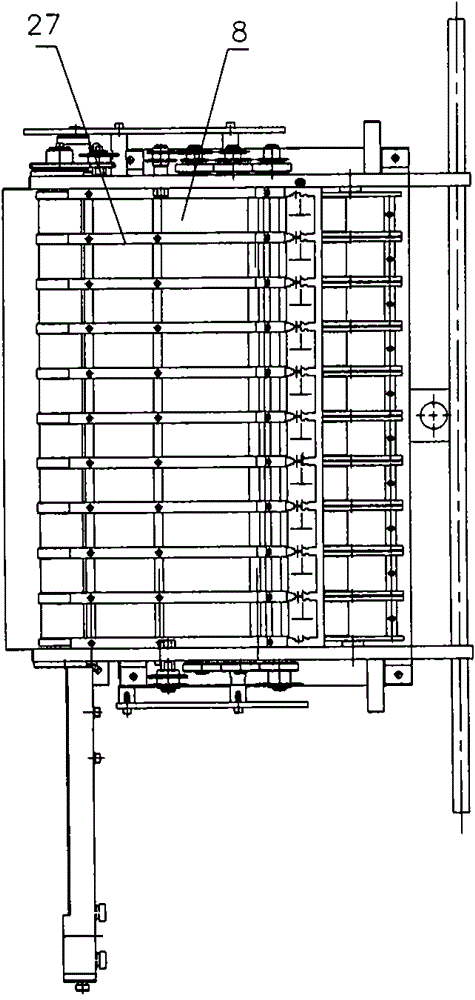

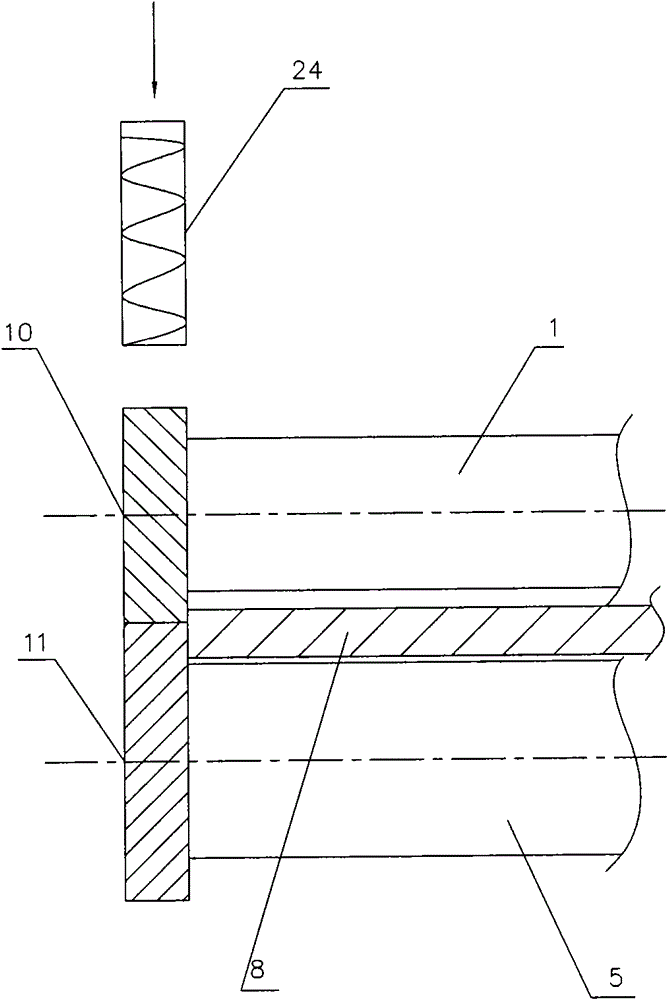

[0042] During specific implementation, the diode raw material is poured into the vibration selection bin 28, and the raw material gradually enters the spiral material selection channel A281 to flow forward through electromagnetic vibration. The material port A283 and the adjustable comb port A282 can dredge the diode raw materials queued into the spiral material selection channel A281 to avoid congestion, and the fallen diode materials return to the vibrating material selection bin 28 from the return port 297 and continue to flow forward After dredging, the raw material passes through the adjustable material selection port A283. At this time, a small amount of diodes with a bending degree greater than 90 degrees can be blocked, and the dropped diode raw materials are collected and reprocessed from the sorting and blanking chute 284; in order to ensure Qualified rate, the diodes that can be straightened after being screened by the spiral material selection channel A281 are sent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com