Packaging structure used for integrating surface adhesive type assembly

A surface-mounted, packaged structure technology, applied in electrical components, electrical solid-state devices, semiconductor devices, etc., can solve the problems of increasing the volume of the circuit carrier, increasing the volume of the circuit carrier, and reducing the volume, etc., to improve the bonding strength. , Improve the matching between the characteristic impedance of the antenna and the impedance of the system end, and increase the effect of space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

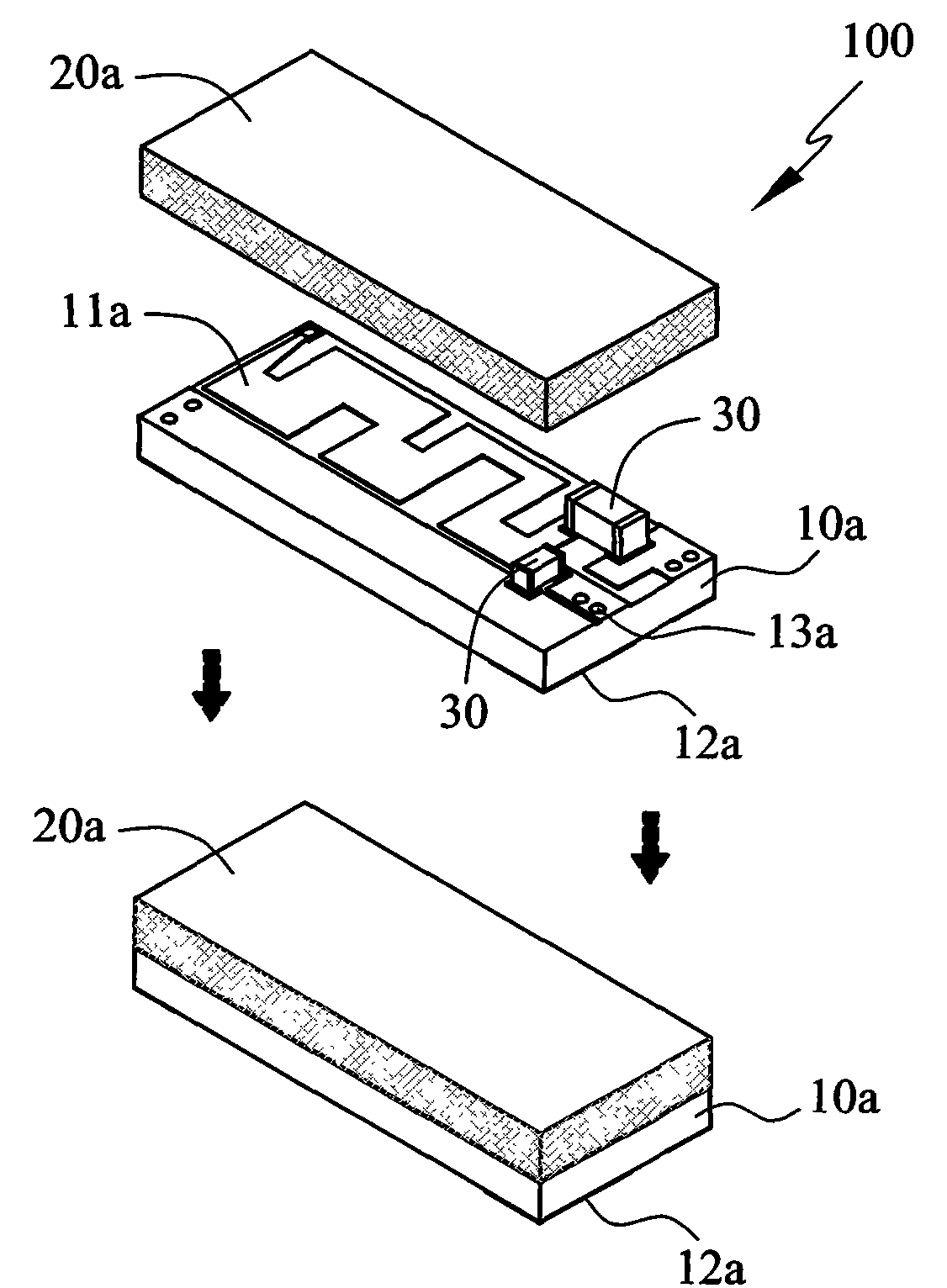

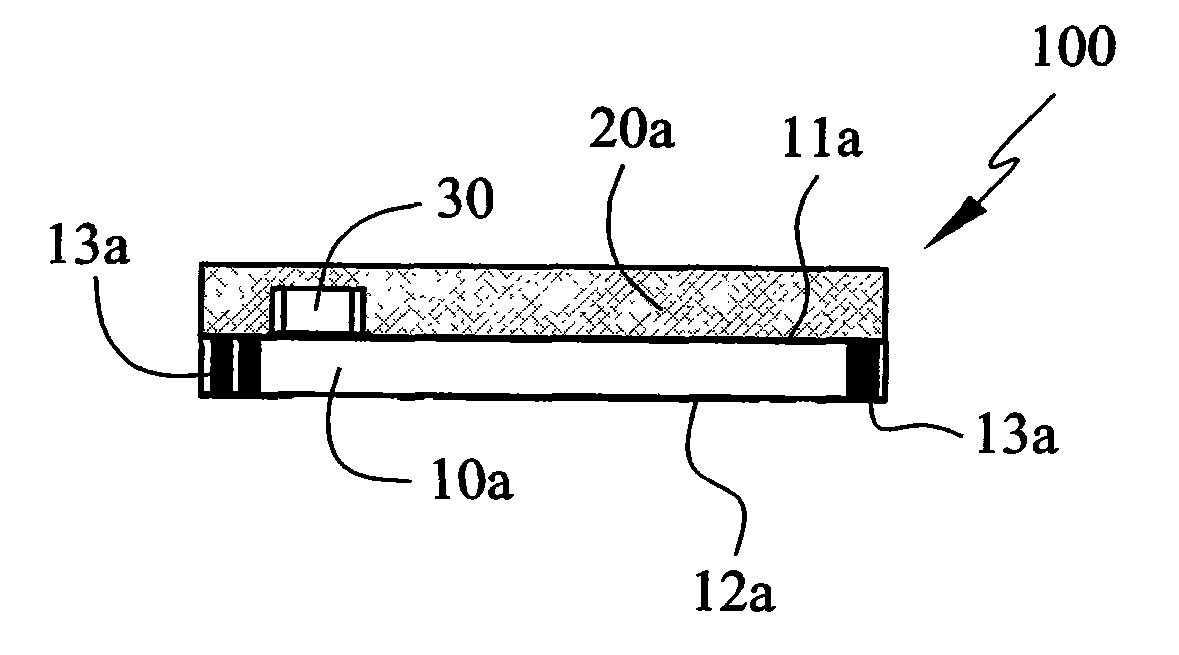

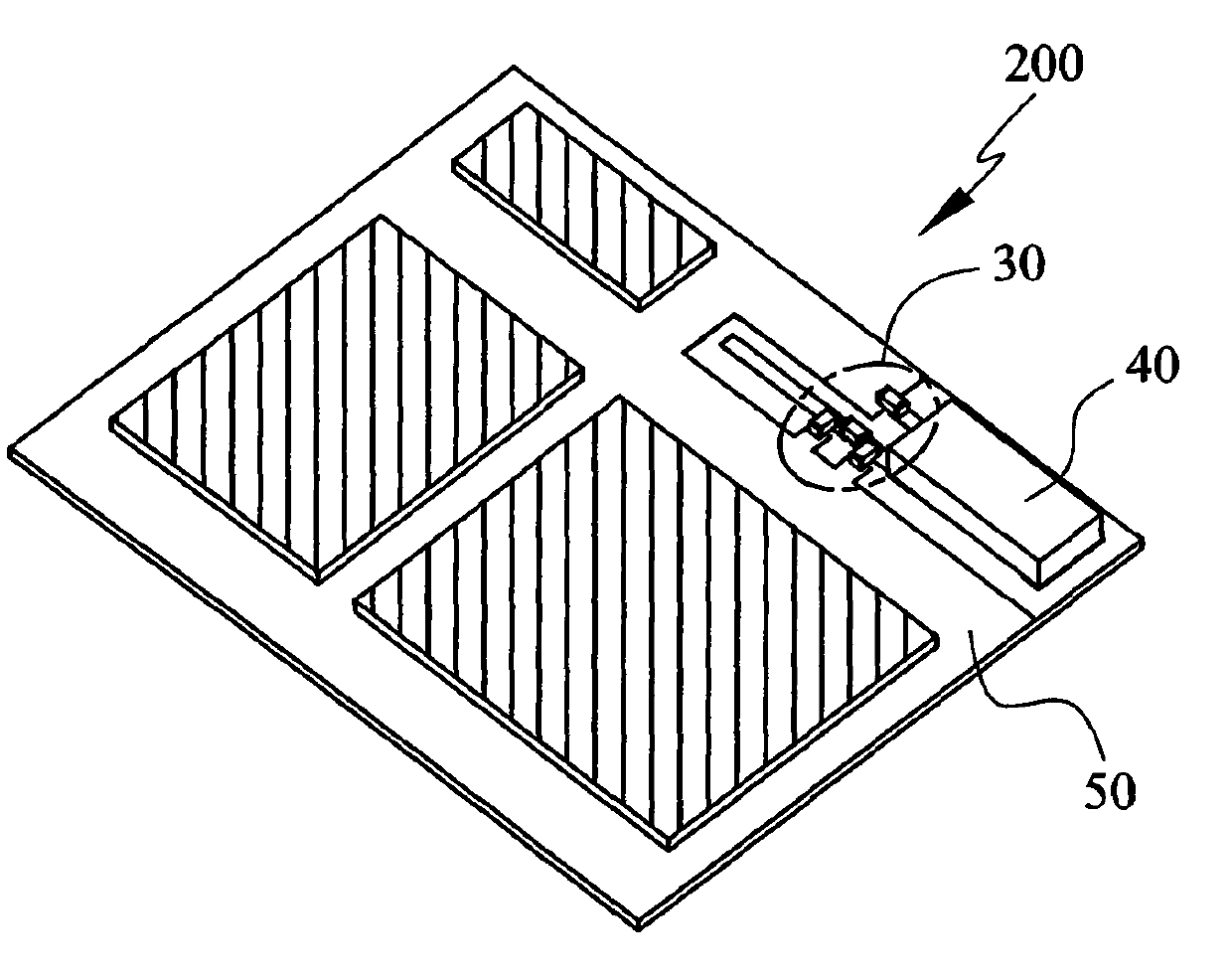

[0052] In order to further have a clearer and more detailed understanding and understanding of the structure and features of the present invention, the novelty and other features of the present invention are illustrated with preferred embodiments, and detailed descriptions are as follows in conjunction with the drawings:

[0053] Please refer to figure 1 and figure 2 , which is the first preferred example of the present invention, the packaging structure (100) of the integrated surface mount type component includes: a dielectric substrate (10a), a first surface metal layer (11a), a second surface metal layer A layer (12a), a plurality of plated through holes (13a), a plurality of passive components (30), and an encapsulation rubber sheet (20a).

[0054] The dielectric substrate (10a) is a composite material composed of a dielectric resin and glass fiber or a composite material composed of a dielectric resin and a ceramic plate or ceramic powder, and the dielectric constant o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com