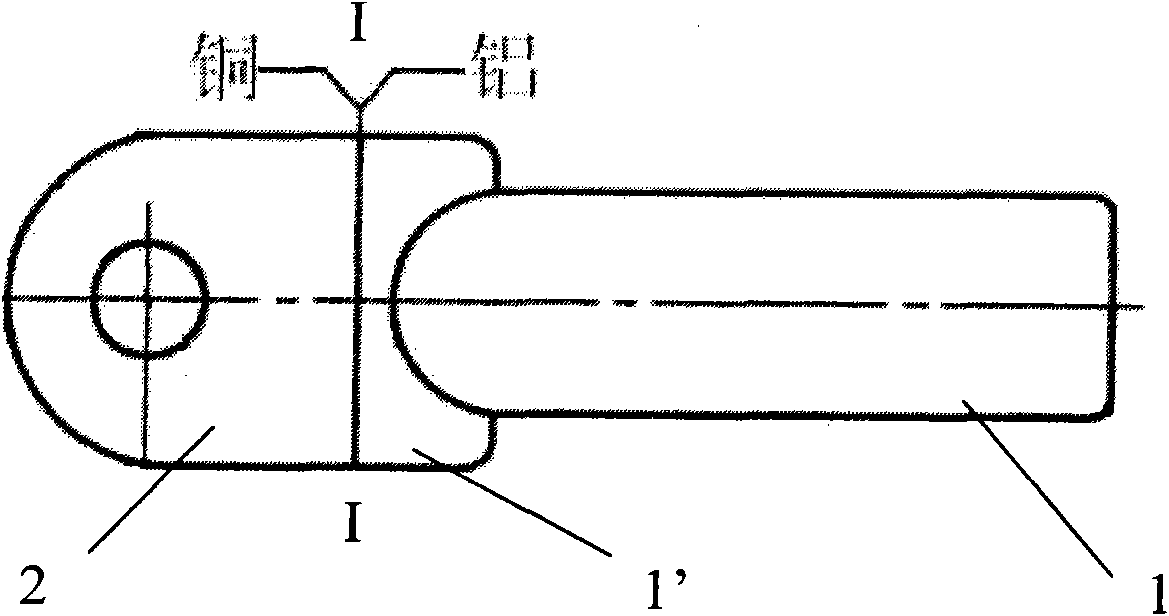

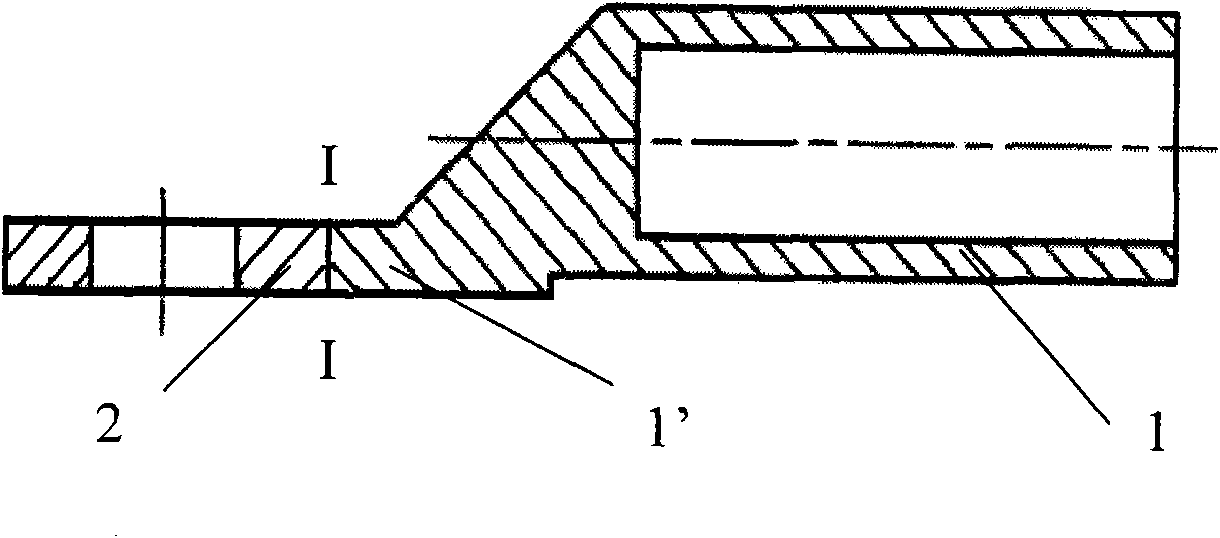

Copper and aluminium transition binding post

A terminal, copper-aluminum technology, applied in the direction of connection, conductive connection, electrical component connection, etc., can solve the problems of many consumables, increased cost, large width and size, etc., to achieve sufficient contact area, ensure smooth transition, and reduce width and size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

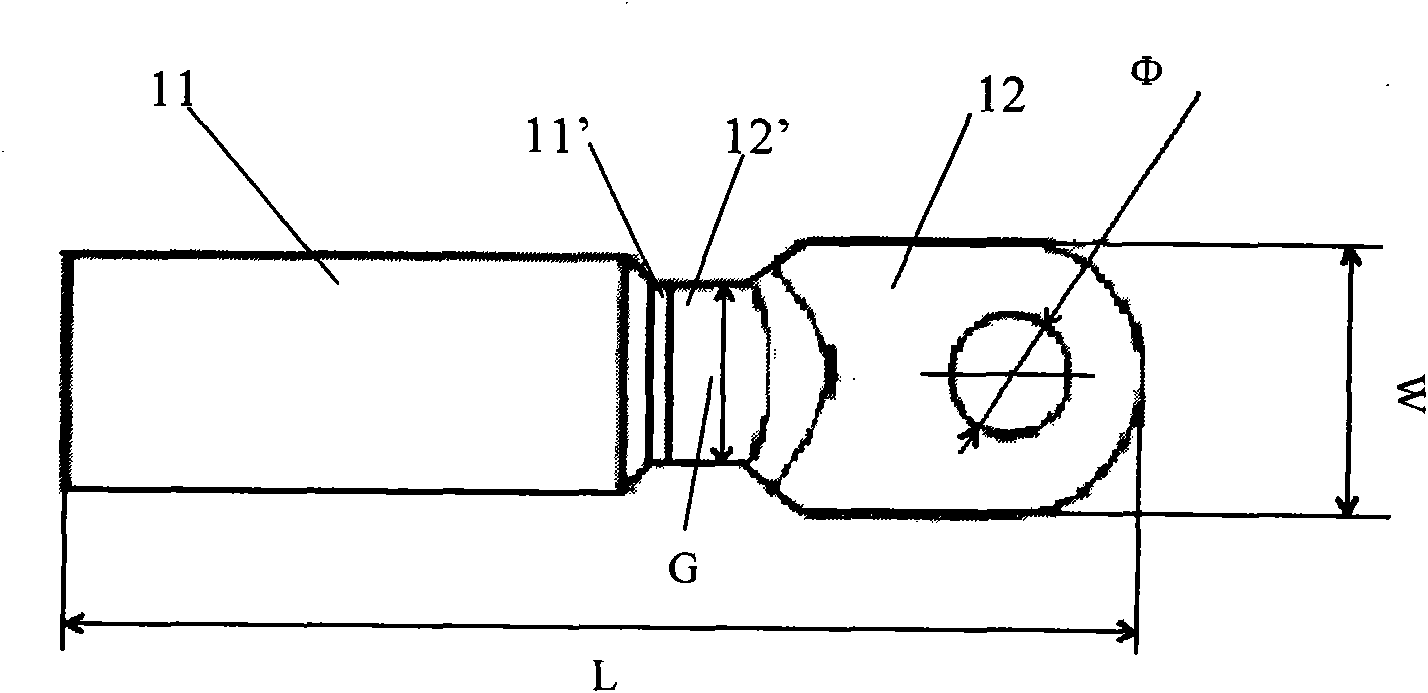

[0025] The copper-aluminum transition terminal is suitable for cable conductors with an area range of 16mm 2 to 500mm 2 within. In the following, the section is 16mm 2 and 400mm 2 Taking the cable conductor as an example, the size parameters of each part of the copper-aluminum transition terminal are given, as shown in Table 1.

[0026] Table 1 Dimensions of relevant parts of copper-aluminum transition terminals

[0027]

[0028] The copper-aluminum transition terminal of the present invention adopts a step-down design, as an embodiment of the present invention, for example, for a conductor cross-section of 400mm 2 For the connecting terminal, the size of the bottom plate part (that is, W) of the copper-aluminum transition terminal defined in the national standard is 52mm, while the copper-aluminum transition terminal of the present invention is based on pure copper 300mm 2 terminal design, than 400mm 2 The terminal level of the terminal is one level lower, that is, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com