Nanocomposite intervertebral fusion cage and preparation method thereof

A nano-composite material, intervertebral cage technology, applied in the direction of fixator, internal fixator, internal bone synthesis, etc., can solve the problems of increasing the brittle fracture of the intervertebral cage, uncontrollable degradation rate, unstable mechanical properties, etc. Achieve good bioactivity and biocompatibility, good toughness, and reduce stress shielding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

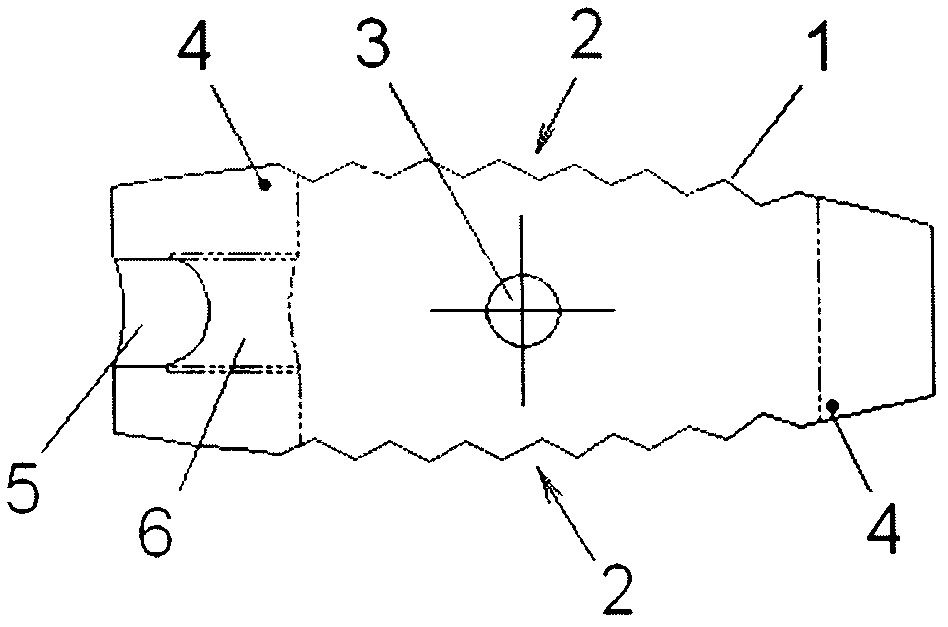

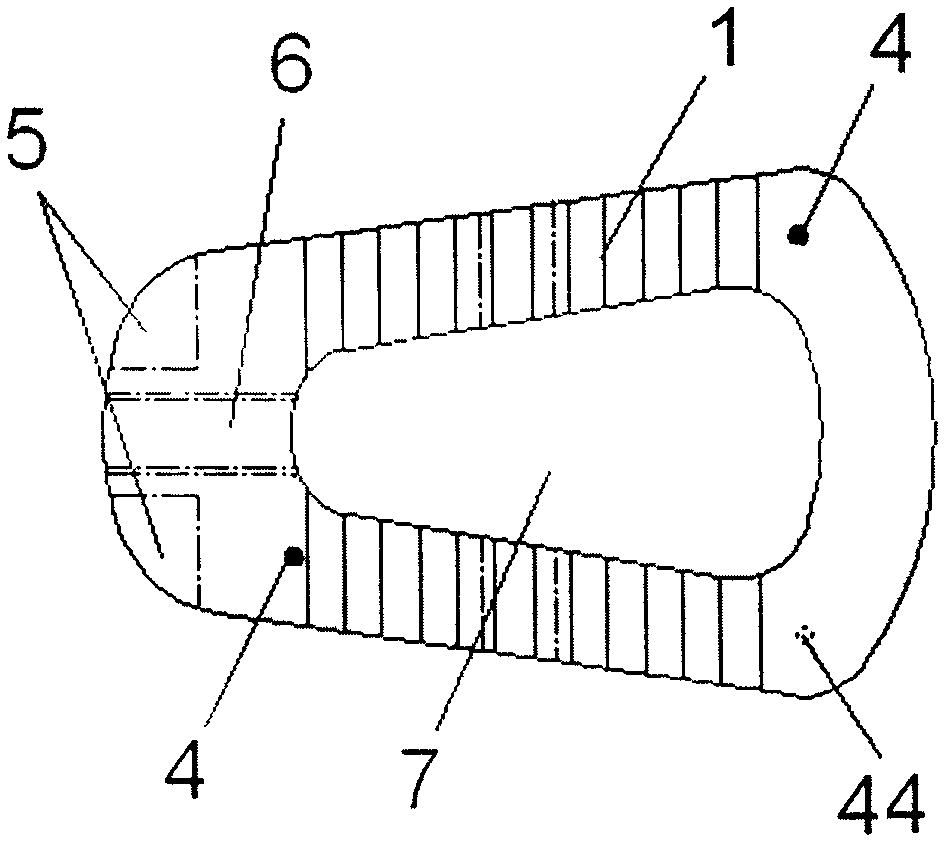

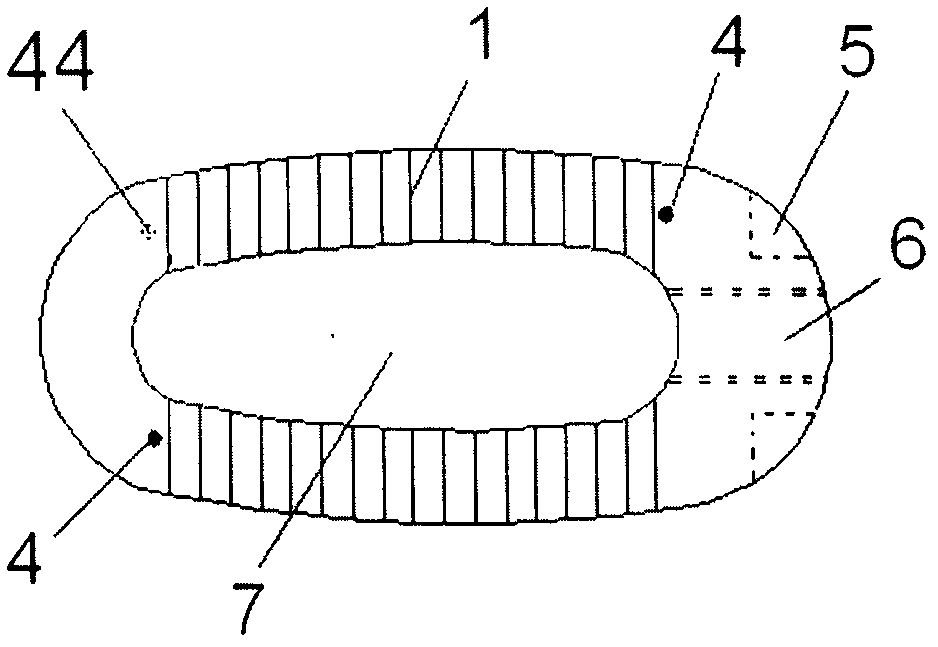

Embodiment 1

[0028] figure 1 with figure 2 The shown nano composite material intervertebral fusion cage of the present invention is composed of nano hydroxyapatite polyamide composite material. Its structure is in a nano-hydroxyapatite-polyamide 66 (or other medical polyamide component) composite matrix structure with a central hole 7 penetrating the upper and lower end faces, and the upper and lower end faces 2 are respectively in the direction of the end faces. It has a curved surface such as a moderately convex arc, and each is provided with a rough surface in the form of a tooth structure 1. On two opposite sides of the base structure, a side hole 3 communicating with the central hole 7 is respectively provided. At one end of the front and rear ends of the base structure in the use direction, a threaded clamping hole 6 is provided, and both sides of the outer hole are provided with a concave clamping structure 5 in a suitable form such as a groove. On both sides of the upper end surfa...

Embodiment 2

[0034] The corresponding injection mold of the intervertebral fusion cage is installed on a conventional plastic injection molding machine, and the nano-hydroxyapatite-polyamide 6 is used as the raw material. The injection molding operation parameters are set as follows: melt temperature 220℃ and injection temperature 225℃, injection pressure 90Mpa, injection speed 10mm / s, holding pressure 60Mpa(, holding pressure time 5s (adjustable within 3~10s) , The cooling time is 20s, the mold temperature is 100°C (adjustable within the range of 100-110°C), and the nanocomposite intervertebral fusion device can be obtained by removing the surface from the mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com