Welding method for diamond abrasive particles

A welding method and diamond technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve the problems of limited size of brazing tools and long brazing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

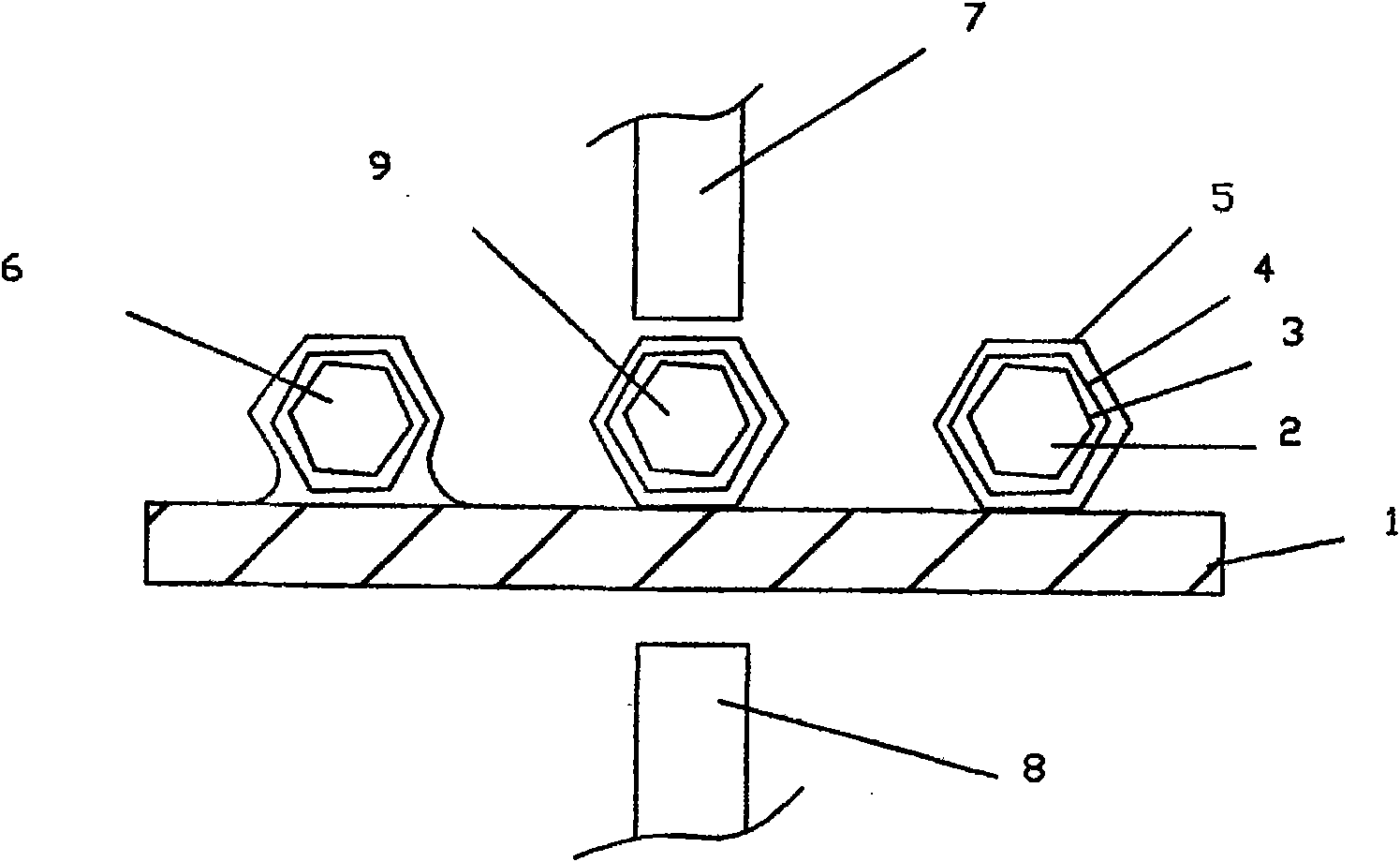

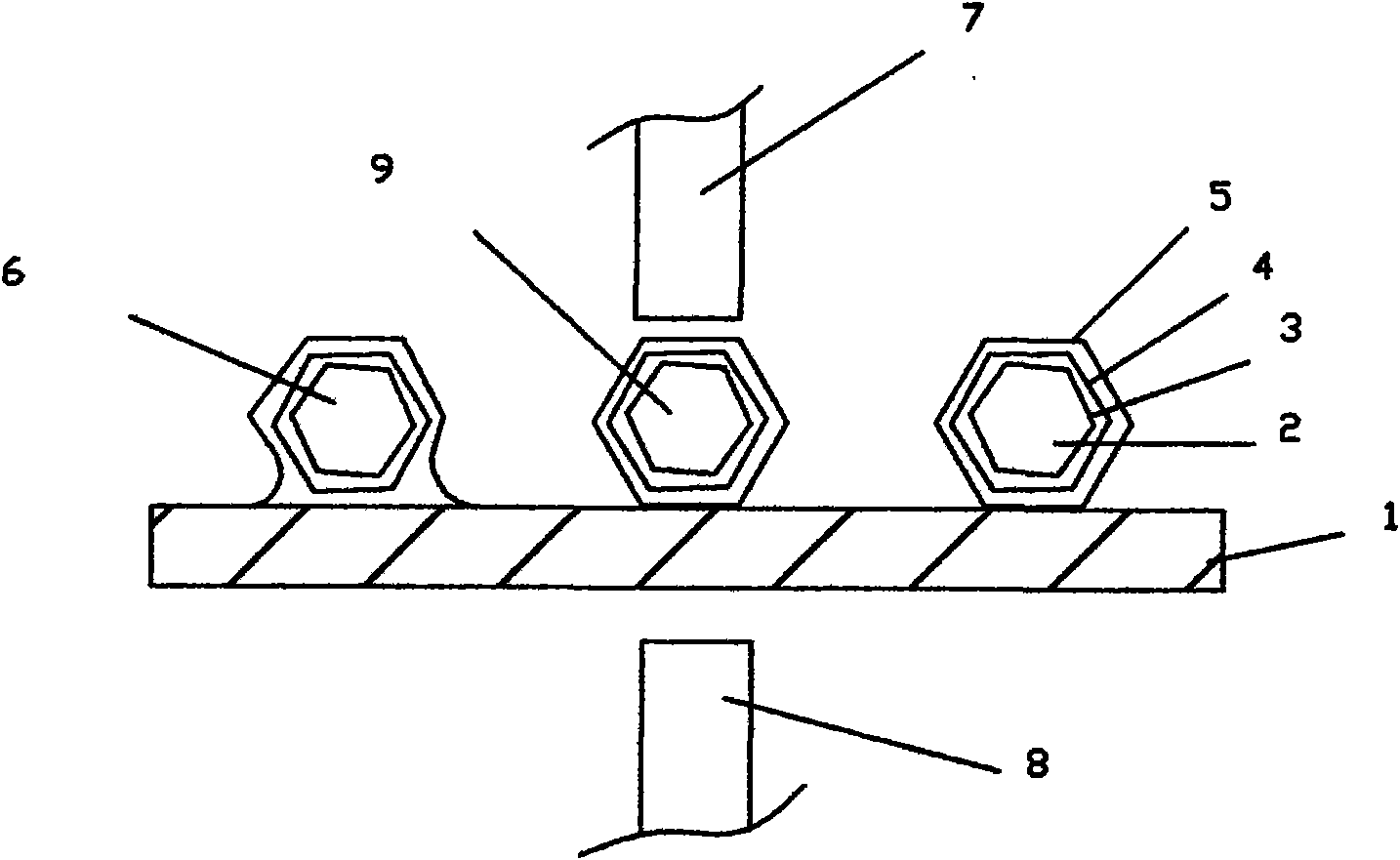

[0007] Embodiment: the diamond abrasive grain 9 that has composite coating is placed on substrate 1, the electrode of spot welder is aligned with diamond abrasive grain, starts spot welder, and the upper electrode 7 of spot welder and lower electrode 8 pair diamond abrasive grain 9 and the matrix 1 carry out the process of pressurization, discharge welding, maintenance, and rest to complete the welding of the diamond abrasive grains 9 and the matrix 1, then move the position, and then weld the next grain or the next batch of diamond abrasive grains. The thickness of the abrasive grain coating and the spot welding parameters can easily adjust the density of diamond abrasive grains and the edge height of diamond abrasive grains to meet the needs of customers; on the other hand, due to its fast welding speed, there is basically no waste gas and liquid in the welding process , it is easy to realize automatic production. To further reduce thermal damage to diamond abrasive grains, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com