New water flushed fertilizer and production method thereof

A production method and flush fertilization technology, applied in fertilization device, fertilizer mixture, application, etc., can solve the problems of slow absorption and low absorption rate, and achieve the effect of fast absorption, high absorption rate of crops, balanced and rich nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The present invention is a new type of fertilization and its production method. The fertilization is composed of the following substances: bamboo vinegar, urea, potassium dihydrogen phosphate, potassium nitrate, amino acids, glucose, boric acid, and the mass percentage of each component is 59.2%, 59.2%, 11%, 5%, 13.6%, 3%, 5%, 3.2%.

[0024] The production method of this novel flushing fertilization comprises the following steps:

[0025] The first step is to add amino acid into the bamboo vinegar and dissolve it completely;

[0026] In the second step, boric acid is added and completely dissolved;

[0027] In the third step, add urea and dissolve it completely;

[0028] In the fourth step, potassium dihydrogen phosphate is added and completely dissolved;

[0029] Step 5, add potassium nitrate and dissolve it completely;

[0030] Step 6, add glucose and dissolve completely;

[0031] The seventh step is to filter the formed mixed solution to remove the residue.

[...

Embodiment 2

[0034] The present invention relates to a novel fertilization method and its production method. The fertilization method is composed of the following substances: bamboo vinegar, urea, potassium dihydrogen phosphate, potassium nitrate, amino acids, glucose, boric acid, and biologically active enzymes. The mass percentages of each component are respectively 59%, 11%, 5%, 13.6%, 3%, 5%, 3.2%, 0.2%.

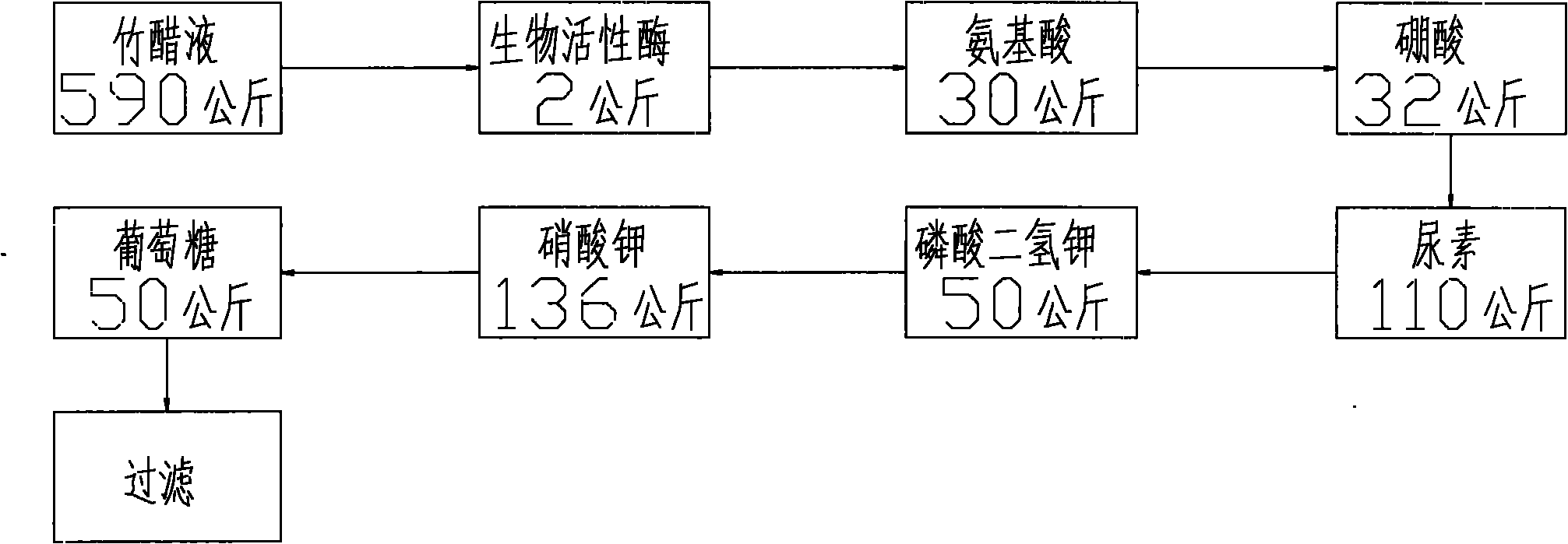

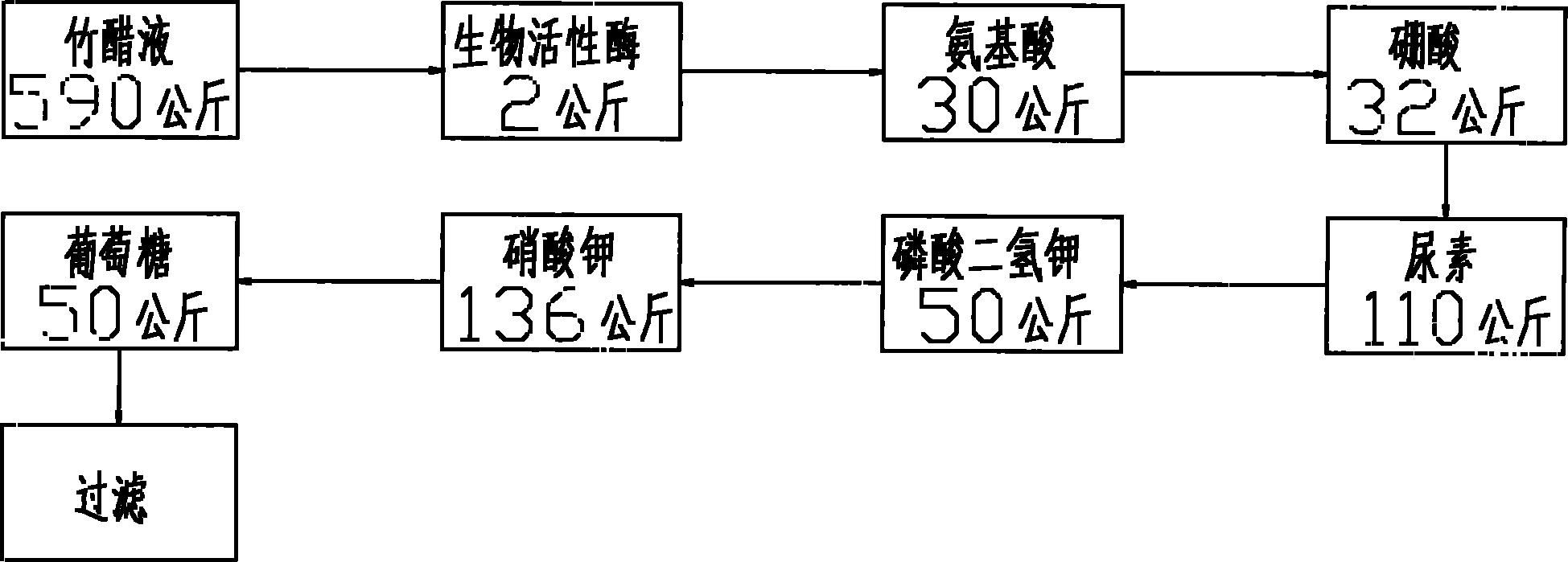

[0035] The production method of this novel flush fertilization comprises the following steps (as figure 1 ):

[0036] The first step is to add amino acid into the bamboo vinegar and dissolve it completely;

[0037] In the second step, add biologically active enzymes and dissolve them completely;

[0038] In the third step, add boric acid and dissolve it completely;

[0039] In the fourth step, add urea and dissolve it completely;

[0040] The fifth step, add potassium dihydrogen phosphate, and completely dissolve;

[0041] Step 6, add potassium nitrate and dissolve it completely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com