Method for producing alpha-olefin by using vegetable oil and fat

A technology of vegetable oils and olefins, applied in the field of production of α-olefins, to achieve the effects of reducing hydrocarbon partial pressure, reducing coking, and stabilizing supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

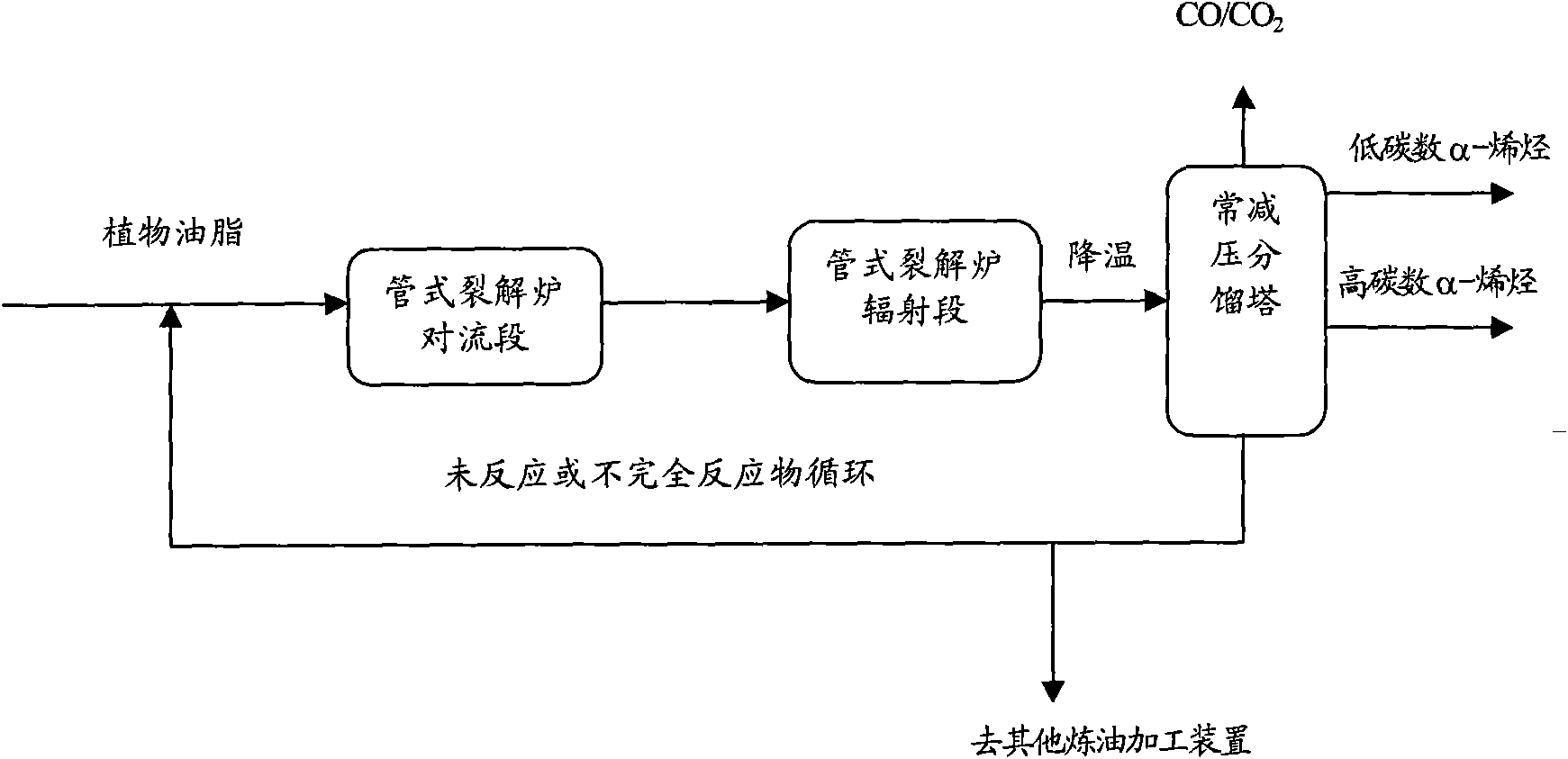

[0026] A preferred embodiment of the present invention is: vegetable oil is used as the raw material of the thermal cracking reaction, heated to 250°C-450°C through the convection section of the tubular cracking furnace, and then enters the radiation section for high-temperature cracking reaction. The reaction conditions are: the cracking furnace outlet temperature is 560-600°C, preferably 580-600°C; the cracking furnace outlet pressure is 0.1Mpa-0.5Mpa; the reaction residence time is 2-30s, preferably 5-20s. After the reaction product is cooled by the quenching boiler and cracking quencher, α-olefins with different carbon numbers are separated in conventional atmospheric and vacuum fractionation towers, and the CO / CO produced by the reaction is separated at the top of the atmospheric fractionation tower. 2 , the unreacted material collected at the bottom of the fractionation tower (which contains unreacted vegetable oil and incompletely reacted intermediate macromolecular subs...

Embodiment 1

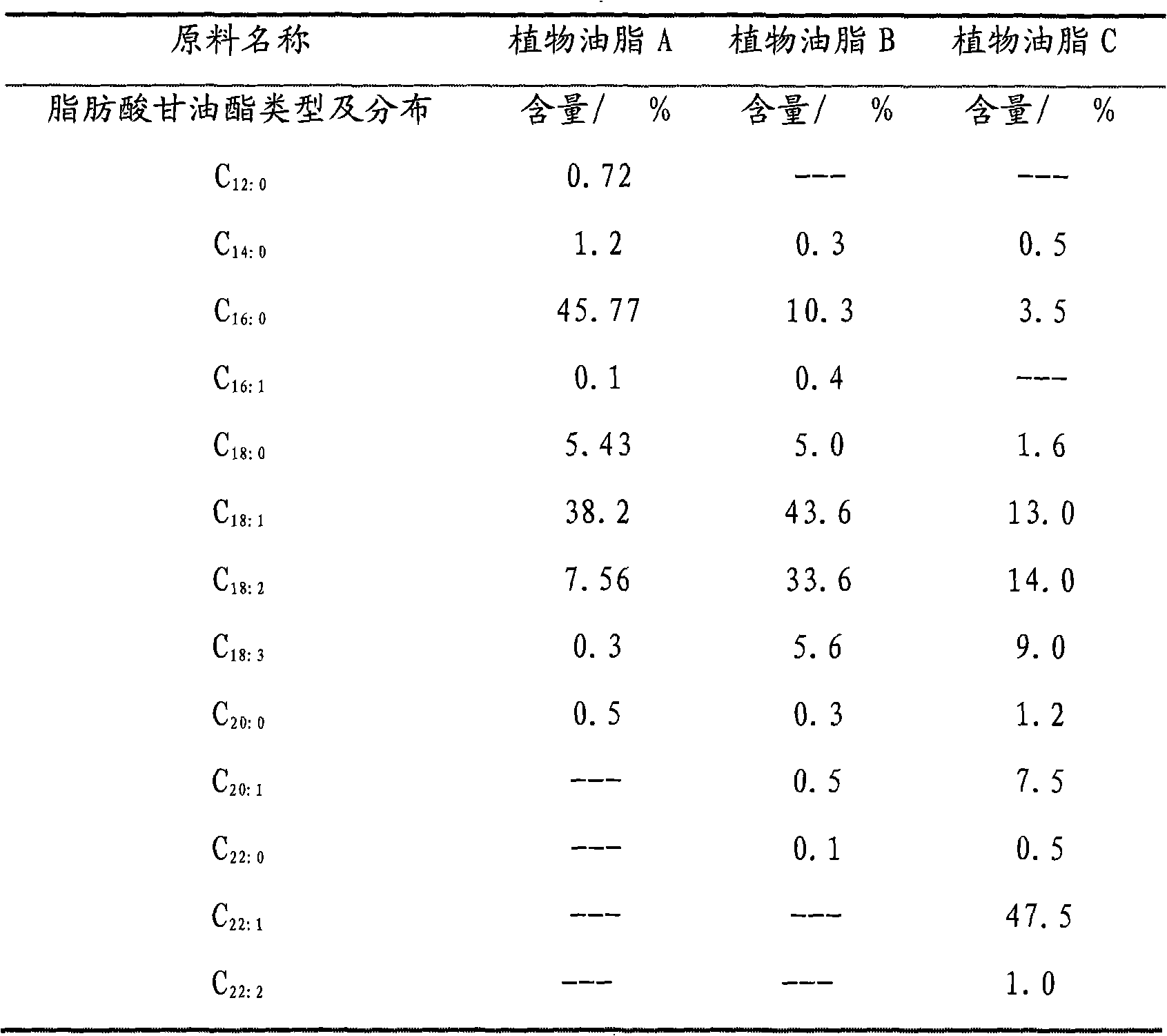

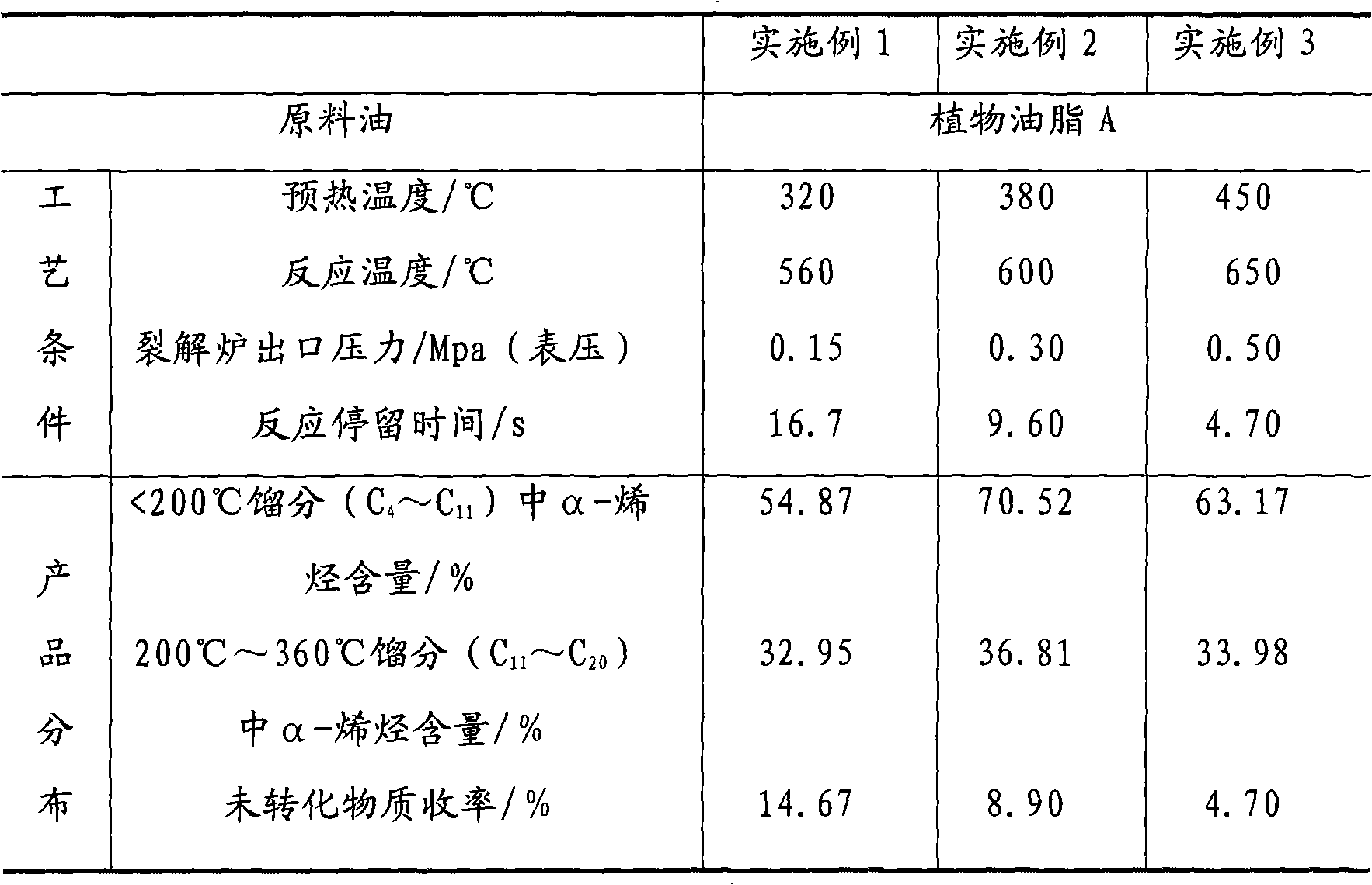

[0030] A kind of vegetable oil A, whose properties are shown in Table 1, is used as the feed material of the simulated thermal cracking performance evaluation test device. The simulated cracking evaluation test device consists of five parts: feed system, raw material preheating, cracking reaction system, quenching system and product separation system. Composition, the whole device is controlled and monitored by a computer. The generated pyrolysis products were separated according to the cut point of 200°C and 360°C, and the fraction >360°C was regarded as the unconverted substance. The main operating conditions of the process of producing α-olefins by thermal cracking are: preheating temperature 320°C, thermal cracking reaction temperature 560°C, cracking furnace outlet pressure 0.15Mpa (gauge pressure), reaction residence time 16.7s, cracking evaluation test The results are shown in Table 2.

Embodiment 2

[0032] Using the same test device and test method and steps as in Example 1, with a kind of vegetable oil A, its properties are shown in Table 1, as the feed material of the simulated thermal cracking performance evaluation test device, the main operation of the process of thermal cracking to produce α-olefins The conditions are: the preheating temperature is 380°C, the pyrolysis reaction temperature is 600°C, the outlet pressure of the cracking furnace is 0.30Mpa (gauge pressure), and the reaction residence time is 9.6s. The cracking evaluation test results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com