Polyvinyl ester-based latex coating compositions

A polyvinyl ester-based, coating composition technology, applied in the carrier field of optical brighteners, can solve problems such as poor rheology and negative effects of paper coating methods, and achieve the effect of improving rheology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

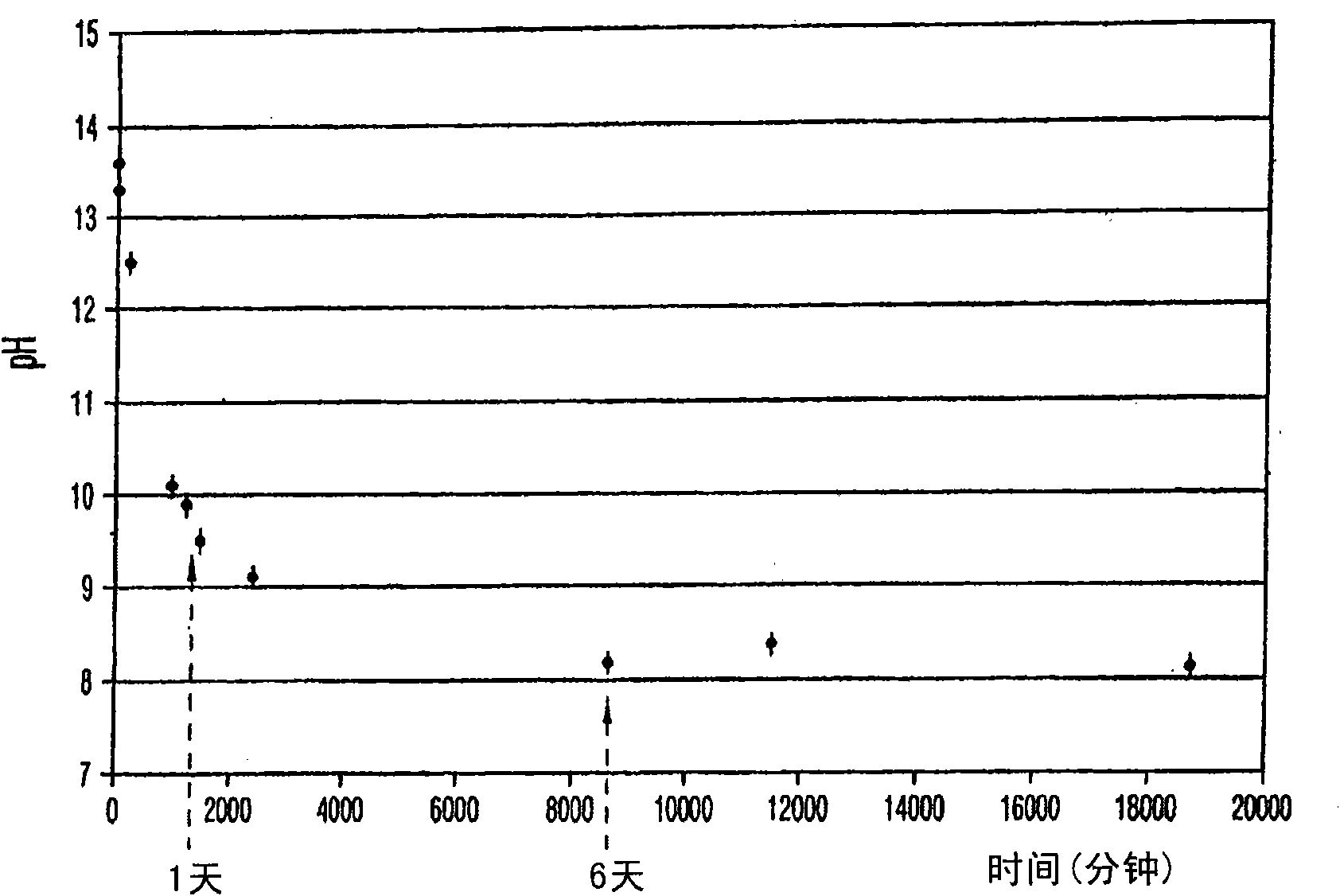

[0059] 500 g of polyvinyl acetate (PVAc)-latex XZ 92806 (The Dow Chemical Company, Midland, MI) containing 40 wt. Partially hydrolyzed at room temperature. This amount of base corresponds to a 20% degree of hydrolysis of the acetate functional groups in the PVAc particles. figure 1 The pH of the dispersion is shown dropping from about pH 13 to about pH 8.5 after 3 days over time. The resulting PVAc-based latex exhibits good storage stability over at least 12 months.

[0060] The PVAc-based latex was then blended with styrene butadiene binder DL 920 (The Dow Chemical Company, Midland MI) at 12.5%, 25%, 37.5%, and 50% by weight of the total polymer content of the blend. Each of the resulting blends was then used as 10 parts dry polymer in a coating composition containing 100 parts of calcium carbonate sold under the trade designation HYDROCARB 90 (Omya, Inc, Proctor VT) and 1 part as OBA sold under the trade designation TINOPAL ABP-Z (Ciba Specialty Chemicals, Basel Switzerla...

Embodiment 2

[0070] 500 g of polyvinyl acetate-butyl acrylate copolymer XU 31631 (The Dow Chemical Company, Midland MI) containing 50.4 wt. % solids was partially hydrolyzed at room temperature by adding 174.4 g of a 10 wt. % sodium hydroxide solution. This amount of base corresponds to a 20% degree of hydrolysis of the acetate functional groups in the PVAc particles. The pH of the dispersion dropped over time from about pH 13 to about pH 9.5 after 3 days. The resulting PVAc-based latex exhibits good storage stability over at least 2 months.

[0071] The PVAc-based latex was then blended with styrene butadiene binder DL 920 (The Dow Chemical Company, Midland MI) at 12.5%, 25%, 37.5%, and 50% by weight of the total polymer content of the blend. Each of the resulting blends was then used as 10 parts dry polymer in a coating composition containing 100 parts of calcium carbonate sold under the trade designation HYDROCARB 90 (Omya, Inc, Proctor VT) and 1 part as OBA sold under the trade desig...

Embodiment 3

[0078] 1.25 parts of each of the PVAc-based latexes of Example 1 and Example 2 were blended with 8.75 parts of styrene butadiene adhesive DL 920 (The Dow Chemical Company, Midland MI). 10 parts of the latex formulated above were then mixed with 100 parts of clay pigment sold under the trade designation Capim SP (Imerys, France), 1 part of TINOPAL ABP-Z (Ciba Specialty Chemicals, Basel Switzerland), and 0.35 parts under the trade designation DST 3250 ( Thickener blends sold by The Dow Chemical Company, Midland MI).

[0079] The pH of each coating composition was then adjusted to pH 8.5 and to a solid composition of 63% using a 10% by weight NaOH solution. The different coating compositions were then coated on wood-free paper and compared to formulations prepared using 0.25 parts of Mowiol 6-98 and 9.75 parts of styrene butadiene binder DL 920.

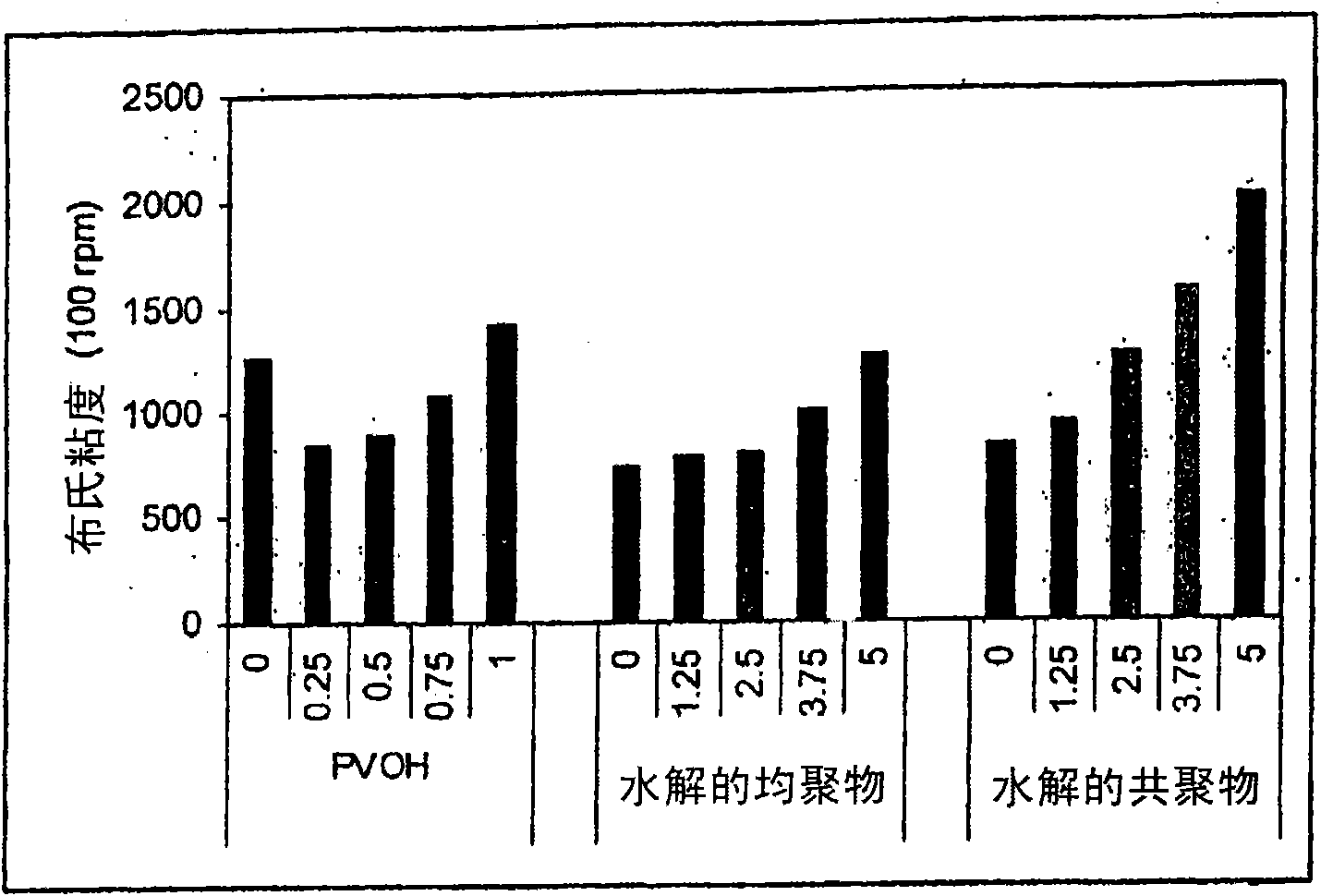

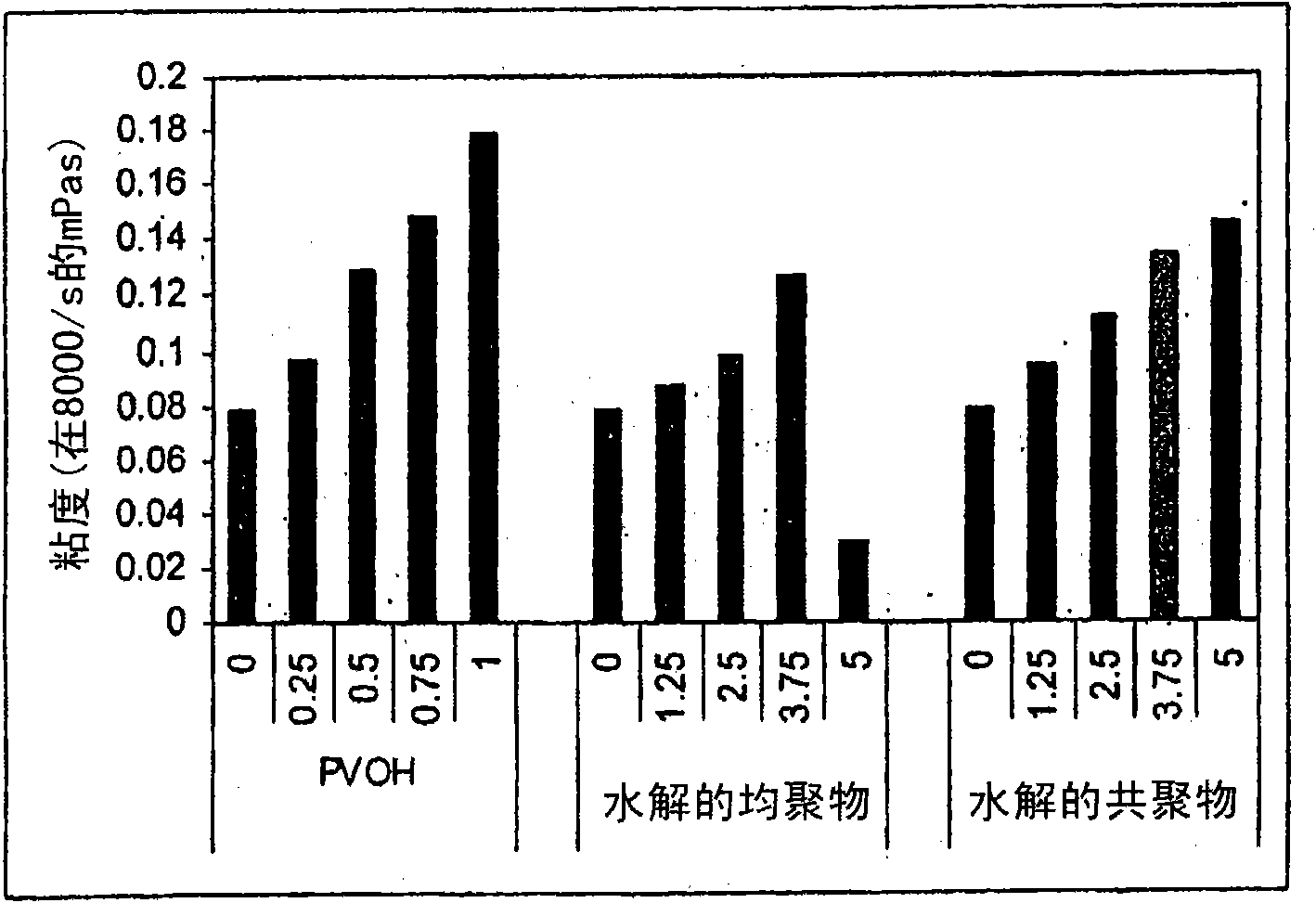

[0080] The viscosities of coating compositions containing PVAc-based latexes were then compared to those containing PVOH. Coating co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com