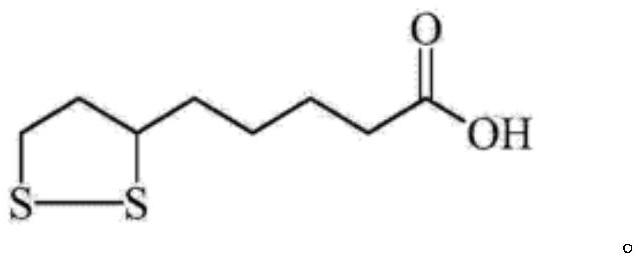

Lipoic acid tablet and preparation method thereof

A technology of lipoic acid tablets and lipoic acid, which is applied in the fields of anti-toxic agents, pill delivery, and pharmaceutical formulations, can solve the problems of low production cost, high proportion of the main drug, easy sticking of lipoic acid tablets, etc., and achieve high production efficiency , product quality is stable, and the effect of reducing the dose of a single dose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

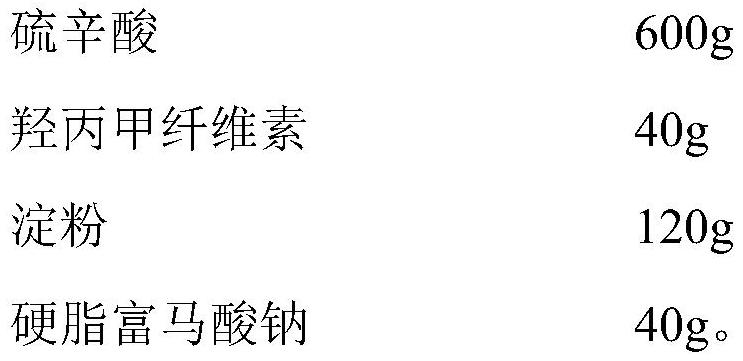

[0036] Described lipoic acid tablet, prescription (1000 consumptions) is as follows:

[0037]

[0038] The mass percent content of the film coating is 3.5%.

[0039] Its preparation method is specifically:

[0040] Put lipoic acid and hypromellose into the high-efficiency mixing granulator, first run at low speed (stirrer 100RPM, flying knife 1500RPM) for 120 seconds, add 150g of purified water, continue to run for 180 seconds, and finally run at high speed (stirrer 150RPM, flying knife Knife 3000RPM) for 30 seconds to produce wet granules. After the wet granules are dried in a hot air circulation drying oven, the granules are sized by a crushing and sizing machine, starch and sodium stearyl fumarate are added, and mixed by a hopper mixer. Just coat it.

[0041] The prepared lipoic acid tablet has smooth and smooth appearance without sticky punch, the disintegration time measured by the disintegration test is 2 minutes, and the dissolution rate measured by the dissolutio...

Embodiment 2

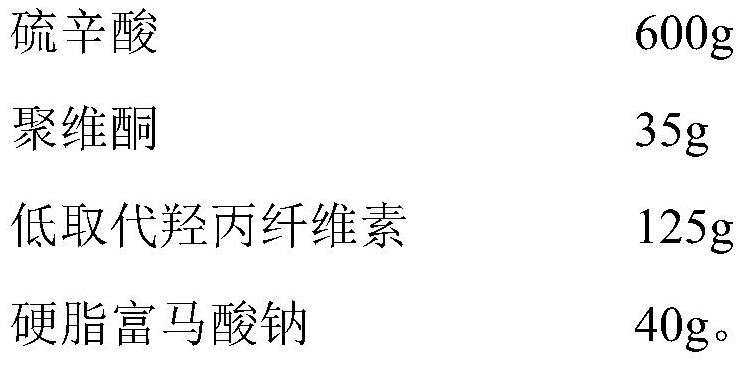

[0043] Described lipoic acid tablet, prescription (1000 consumptions) is as follows:

[0044]

[0045] The mass percent content of the film coating is 3.5%.

[0046] Its preparation method is specifically:

[0047] Put lipoic acid and povidone into the high-efficiency mixing granulator, first run at low speed (100RPM for stirring paddle, 1500RPM for flying knife) for 120 seconds, add 150g of purified water, continue running for 180 seconds, and finally run at high speed (150RPM for stirring paddle, 3000RPM for flying knife) ) for 30 seconds to prepare wet granules. After the wet granules are dried in a hot air circulation drying oven, the granules are sized by a crushing and sizing machine, and low-substituted hydroxypropyl cellulose and sodium stearyl fumarate are added, mixed by a hopper mixer, and then compressed into tablets. Finally, the substrate can be coated.

[0048] The prepared lipoic acid tablet has smooth and clean appearance without sticky punch, the disint...

Embodiment 3

[0050] Described lipoic acid tablet, prescription (1000 consumptions) is as follows:

[0051]

[0052] The mass percent content of the film coating is 3.5%.

[0053] Its preparation method is specifically:

[0054] Put lipoic acid and hydroxypropyl cellulose into the high-efficiency mixing granulator, first run at low speed (100RPM of stirring blade, 1500RPM of flying knife) for 120 seconds, add 150g of purified water, continue to run for 180 seconds, and finally run at high speed (150RPM of stirring blade, 150RPM of flying knife 3000RPM) for 30 seconds to produce wet granules. After the wet granules are dried in a hot air circulation drying oven, the granules are sized by a crushing and sizing machine, microcrystalline cellulose and sodium stearyl fumarate are added, and mixed by a hopper mixer. The substrate can be coated.

[0055] The prepared lipoic acid tablet has smooth and clean appearance without sticky punch, the disintegration time measured by the disintegratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com