Film forming method for biological carrier in internal circulation bioreactor

A bioreactor, biological carrier technology, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problems of unsuitable biological fillers for hanging film, no suitable methods, etc., and achieve shortened film formation. effect of time, reducing shear, increasing chance of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

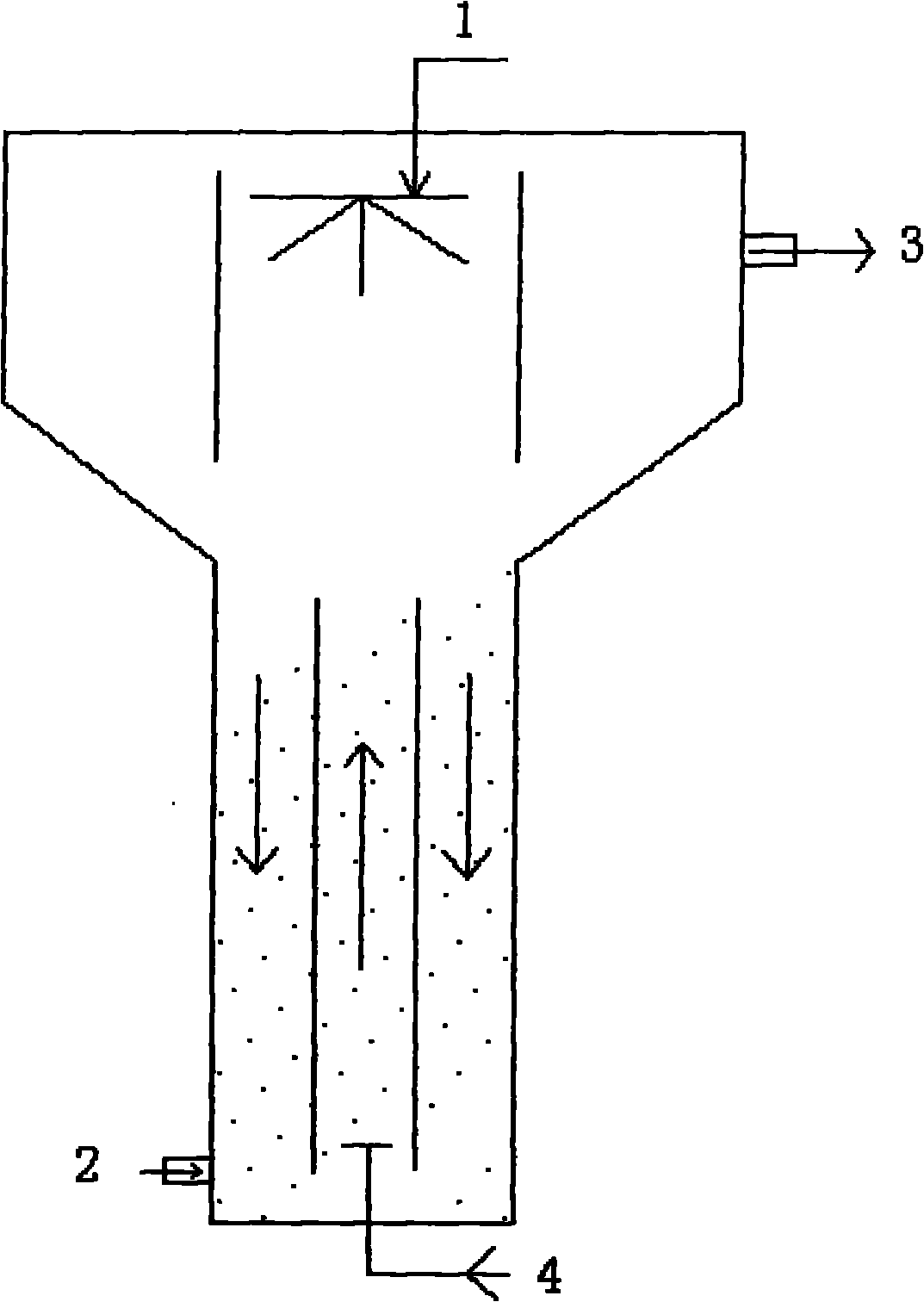

[0026] test in as figure 1 The shown internal circulation bioreactor is carried out, the effective volume of the reactor is 15.5L, and the total volume is 31L.

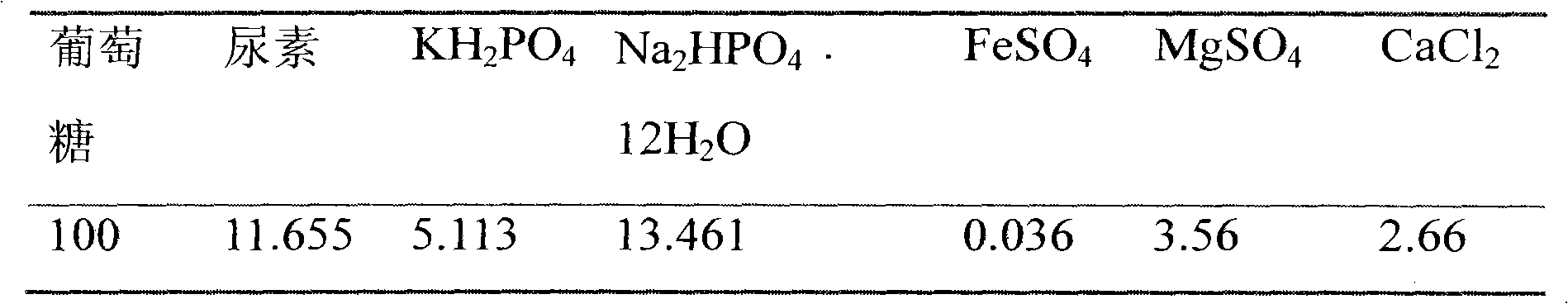

[0027] The wastewater used was artificially prepared, and the wastewater was prepared according to COD:N:P=100:5:1. The specific composition is shown in Table 1. The biological carrier is 0.5-2mm biological ceramsite, and the sludge is collected from the secondary biochemical pool of the sewage treatment plant. The sedimentation tank has been cultivated and acclimated before being added.

[0028] The biological carrier particles accounting for 2.5% of the effective volume of the reactor are added to the reactor from the upper part of the reactor (accounting for 46% of the total biological carrier volume), and then the gas is introduced to make all the particles fluidized, and the sludge spraying device is opened. Spray once every 3 to 5 minutes, and the concentration of inoculated sludge is 1g / 1. After about 20 minut...

Embodiment 2

[0033] The test uses an internal circulation bioreactor with an effective volume of 33L, biological ceramsite with a carrier particle size of 0.5-0.71mm, an inoculated sludge concentration of 2g / L, and a total mass of carrier particles of 2.5kg, which are added to the reactor in three times. The first time is 30% of the total carrier particle volume, and the exposure is 12 hours. The second time is 45% of the total carrier particle volume, and the exposure is 36 hours. The third time is 25% of the total carrier particle volume, and the exposure is 24 hours. The waste water is artificially prepared waste water, COD:N:P=100:5:1, the composition of the waste water is shown in Table 1, and other test operating conditions and steps are the same as in Example 1.

[0034] The influent COD is about 200mg / L, and the HRT is 0.55h. After 3 days of operation, it can be found that there are bell worms attached to the carrier. On the fourth day, a large number of bell worms can be observed o...

Embodiment 3

[0036] The test adopts an internal circulation bioreactor with a total effective volume of 3.16L, and the carrier particle size is 20-40 mesh porous polymer carrier. The composition of the prepared wastewater is shown in Table 1.

[0037] The carrier particles were added to the reactor in three times, the first time was 55% of the total carrier particle volume, and was exposed for 48 hours; 20% of the exposure for 24 hours. Other test operating conditions and steps are the same as in Example 1.

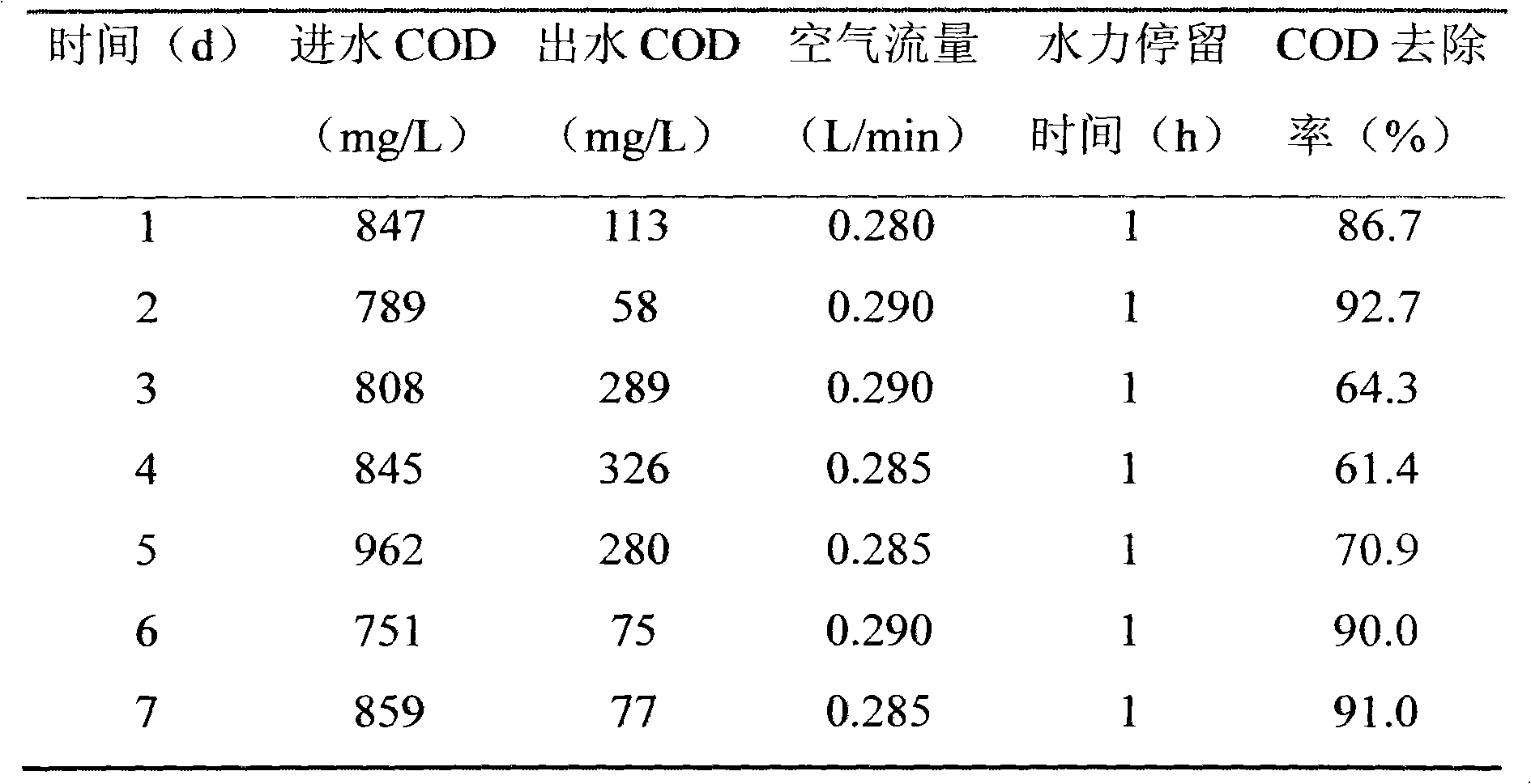

[0038]Table 2 shows the data of film-hanging start-up test. It can be seen from Table 2 that in the first two days of the test start, the COD removal rate was high, which was due to the action of the activated sludge inside the reactor. With the discharge of the activated sludge, the COD removal rate began to decline until the first two days of start-up. On the 5th day, the COD removal rate began to increase, and on the 6th day, the COD removal rate reached more than 90%. The parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com