High-strength concrete composite material as well as preparation method and application thereof

A technology of composite materials and concrete, which is applied in building reinforcements, structural elements, building components, etc., can solve the problems of high cost and inability to give full play to the unique advantages of FRP

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

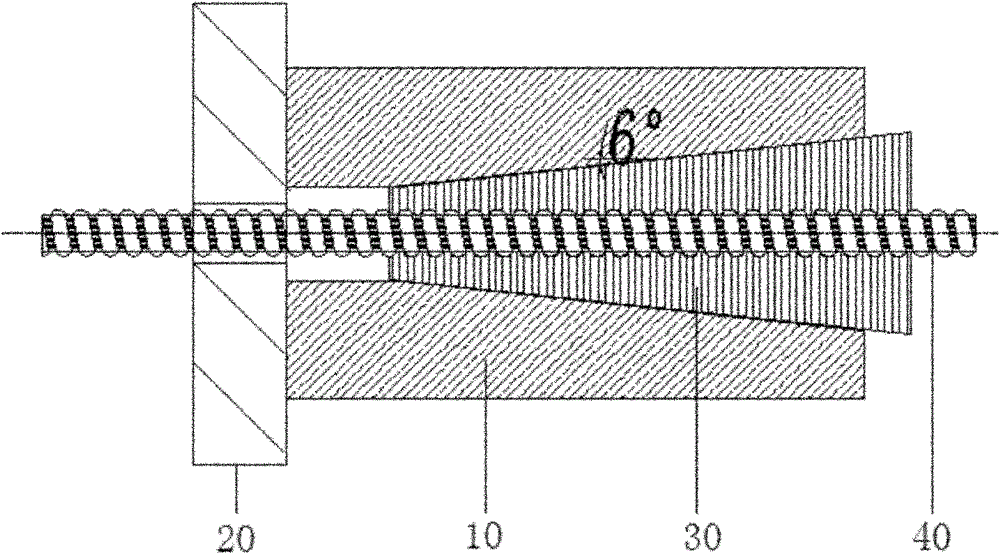

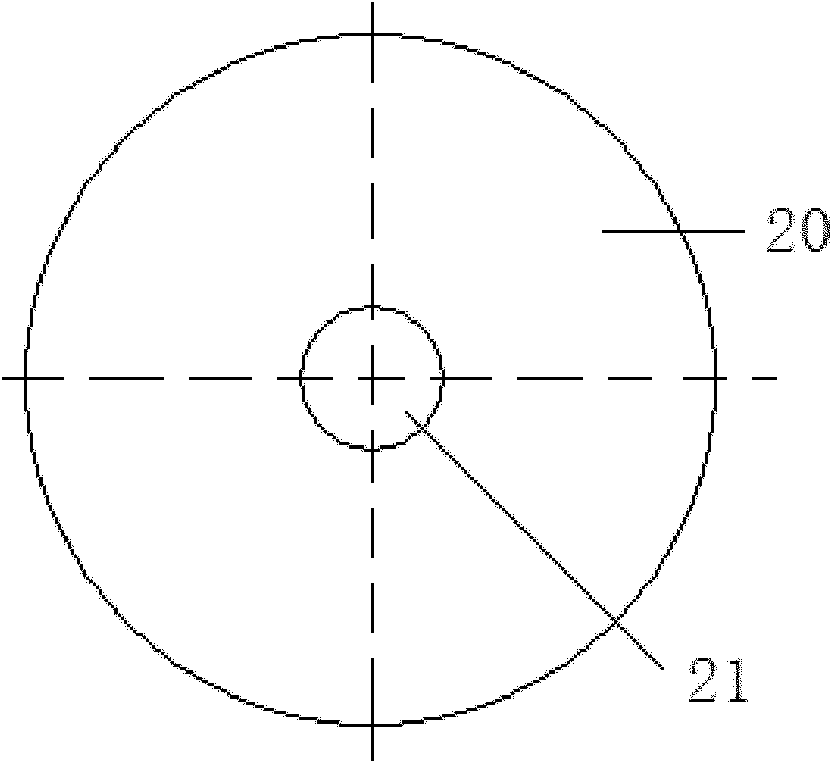

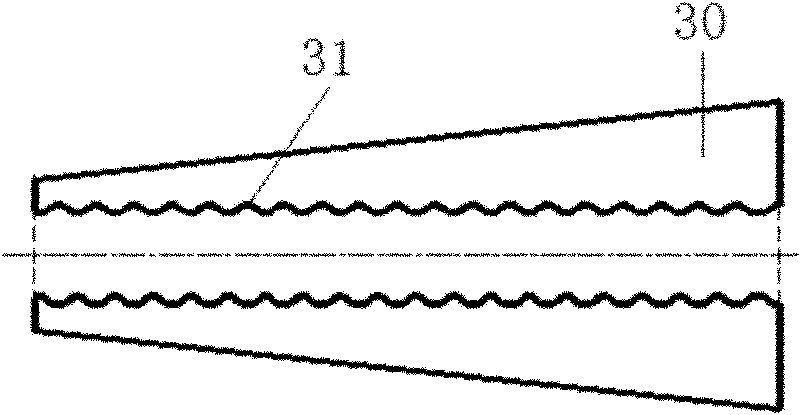

[0051] The following is a detailed description in conjunction with the drawings and embodiments:

[0052] 1. About composite materials

[0053] The best values of its components and their weight percentages are:

[0054] ① Cement: Ordinary Portland cement, 28-day flexural strength of 9.9MPa and compressive strength of 58.1MPa.

[0055] ②Sand: standard sand, with a particle size range of 0.125~0.65mm, natural river sand, grading in zone III.

[0056] ③Silica fume: SiO 2 ≥90%, particle size below 1μm, average particle size 0.11μm, density 2.214g / cm 3 .

[0057] ④Quartz powder: density is 2.626g / cm 3 About, the average particle size is less than 48μm.

[0058] ⑤Superplasticizer: The main component is β-naphthalenesulfonic acid formaldehyde high condensate. When the content is 2%, the water reducing rate is 20%.

[0059] ⑥ There is no special requirement for calcined bauxite aggregate.

[0060] ⑦Aramid fiber: diameter is 12.7μm, length is 6mm.

[0061] 2. About the method

[0062] Step ②:

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com