Method for preparing soluble starch

A manufacturing method and soluble technology, applied in the field of starch production, can solve the problems of no stable process route products, unreasonable control of technical parameters, high reducibility of soluble starch, etc., achieve good quality, strong innovation, and improve the effect of preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

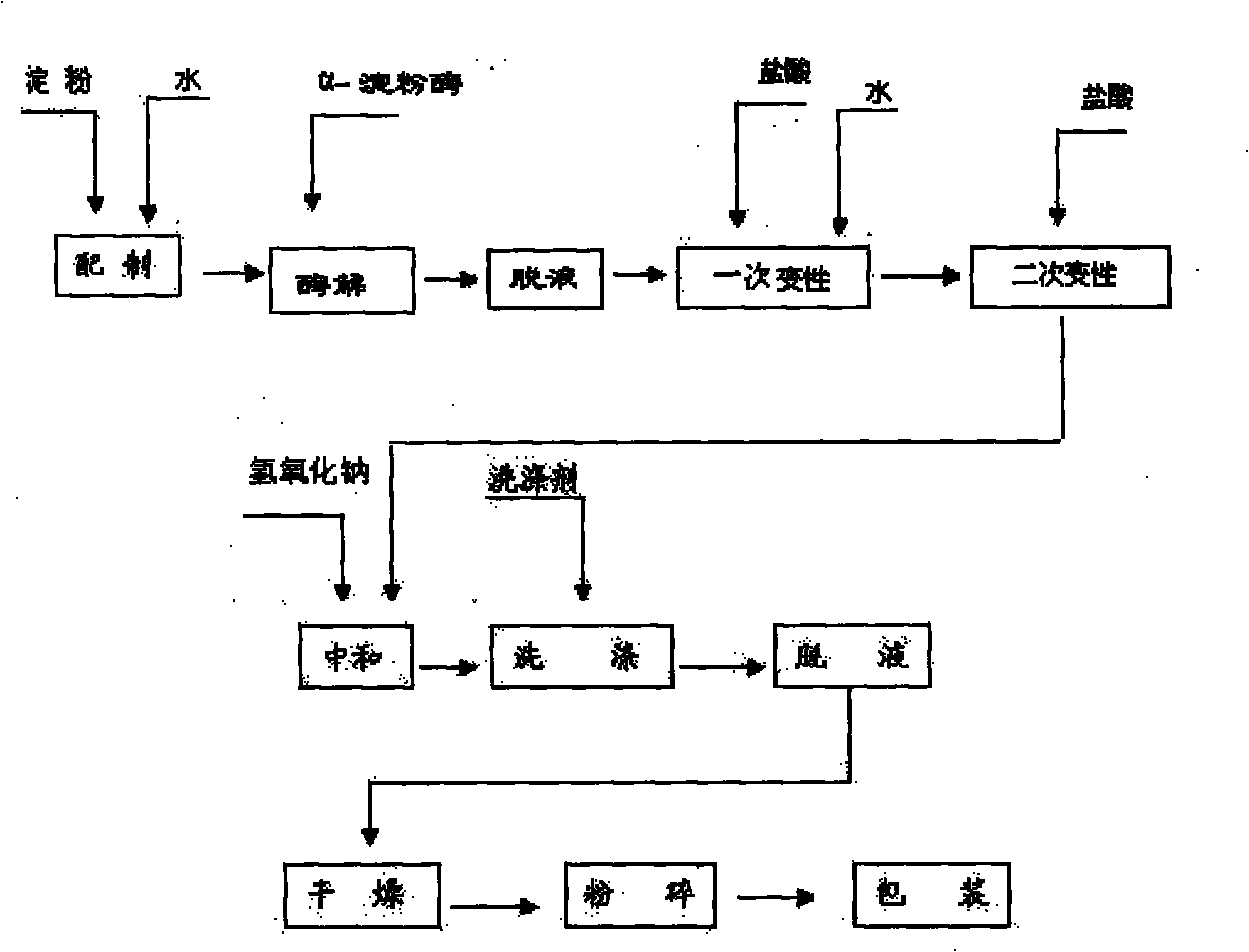

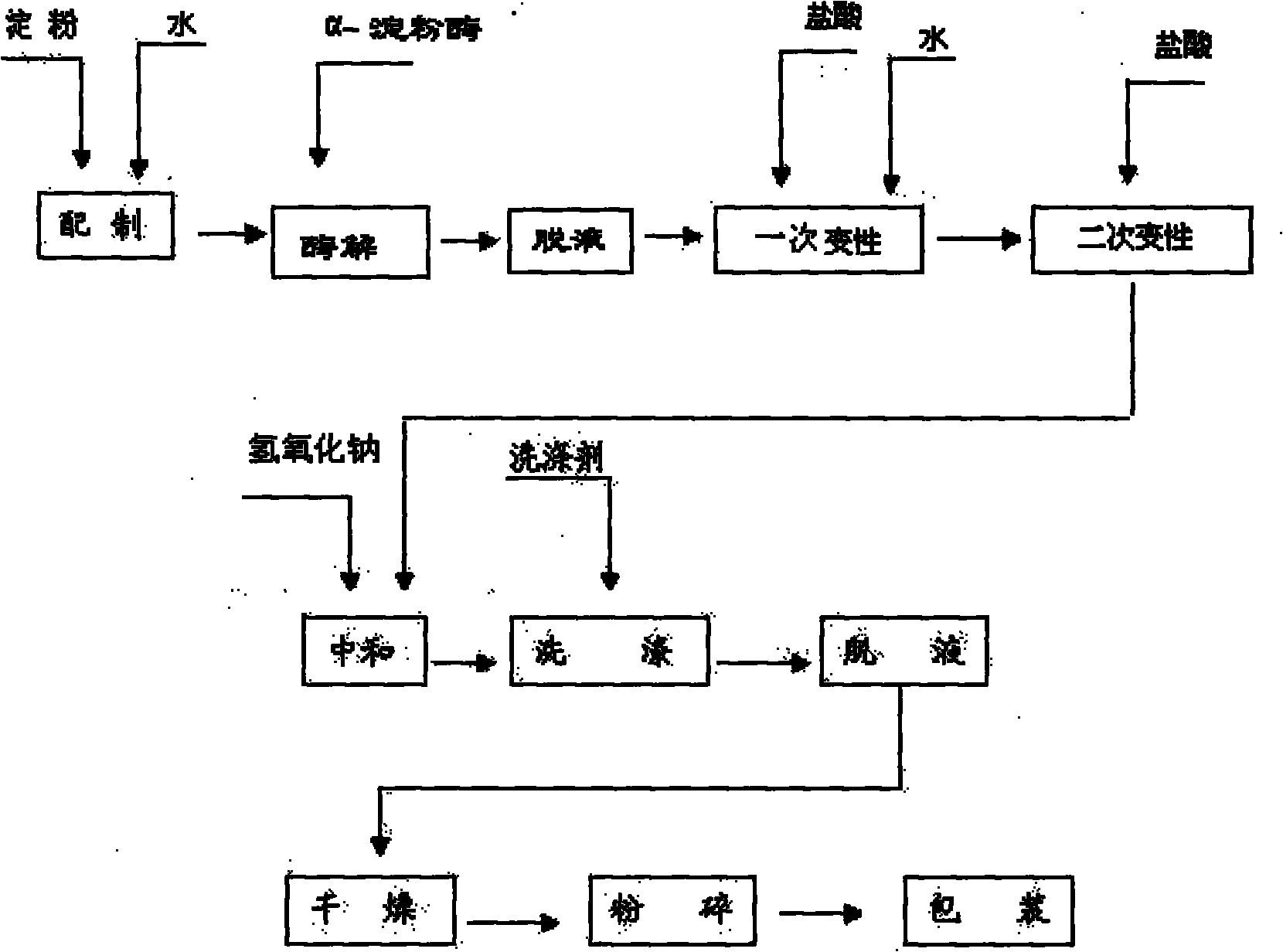

Method used

Image

Examples

Embodiment Construction

[0028] In the stainless steel enzymatic hydrolysis kettle, add 100 kg of starch, 120 kg to make 40% starch milk, start stirring, add 3 kg of α-amylase, heat up to 50 ° C, react for 30 minutes, and centrifuge to remove the liquid. Then it was made into 40% starch milk, then added to the stainless steel reaction kettle, and 15 liters of 31% hydrochloric acid solution was added (it was formulated into a hydrochloric acid solution with a concentration of 5.96%), acidified at 40°C for 2 hours, and then heated to 50°C , add dropwise the remaining 15 liters of hydrochloric acid solution (it is formulated into a hydrochloric acid solution with a concentration of 5.96%) for acidification, the jacket is heated by hot water, the temperature of the material is maintained at 50 ° C, and it is incubated for 2 hours, and then 10% hydroxide is added Neutralize the remaining acid with sodium, add 200 kg of water to wash twice, centrifuge and deliquify, send the centrifuged material to a vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com