Method for manufacturing test piece of hgdrogen induced cracking (HIC) and sulfide stress cracking (SSC) of welding material melting laid metal

A technology of deposited metal and stress cracking, which is applied in the preparation of test samples, metal processing equipment, welding equipment, etc., can solve the problems of meeting actual requirements and the inability of sulfur-resistant welding materials to pass the sulfur-resistant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1: Selection of surfacing test plate

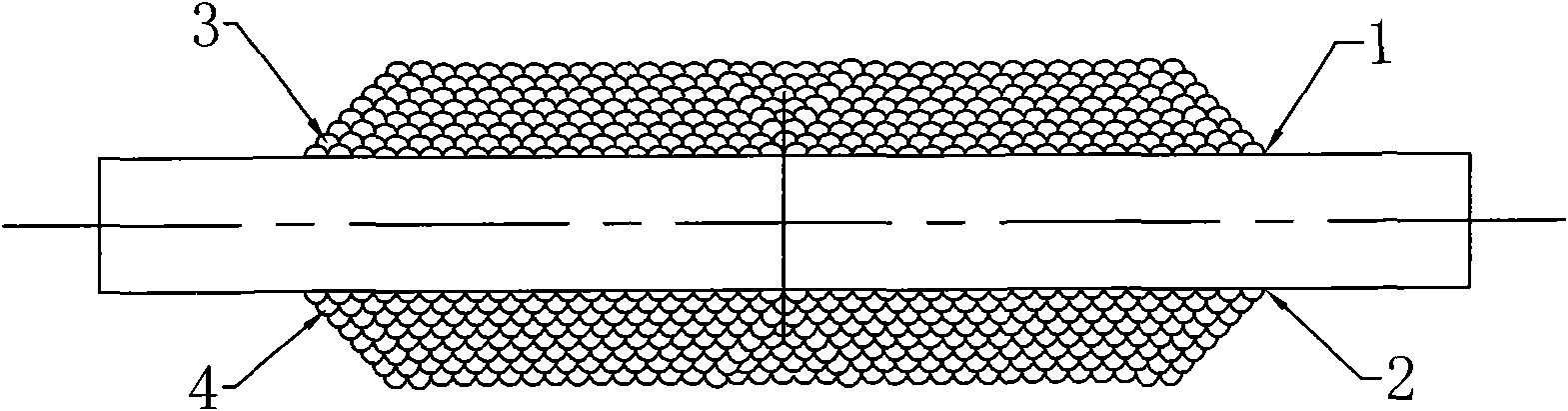

[0034] see figure 1 :

[0035] In order to ensure that there is no obvious deformation of the test plate during the surfacing process, which will affect the mechanical properties of the deposited metal of the welding consumables, and at the same time avoid excessive impurity elements from being mixed into the deposited metal of the welding consumables, the material of the test plate selected for surfacing welding is tensile The strength is not lower than 490MPa, and the specification is 300×200×30mm low-alloy material 16MnR.

[0036] Step 2: Selection of surfacing welding method

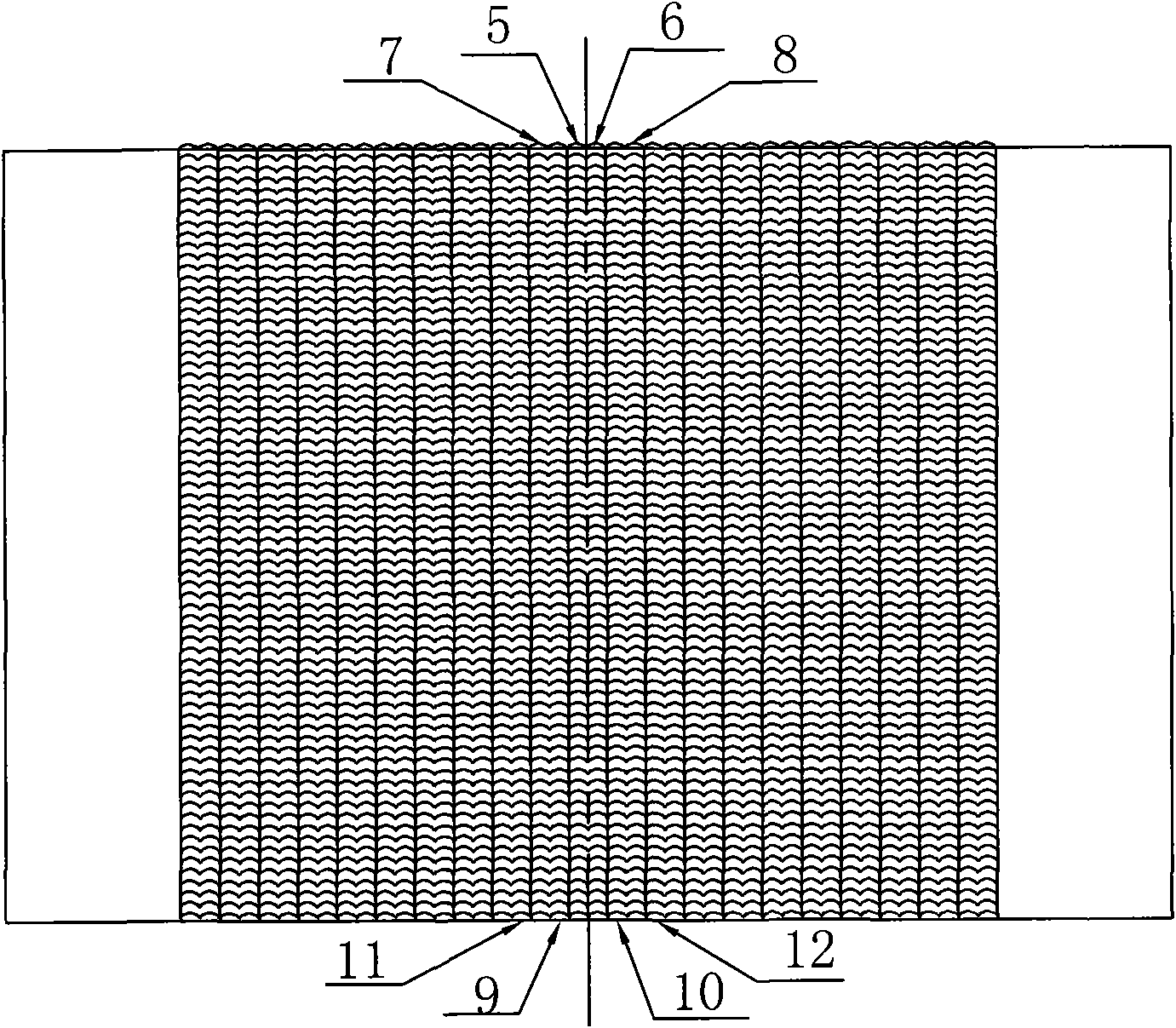

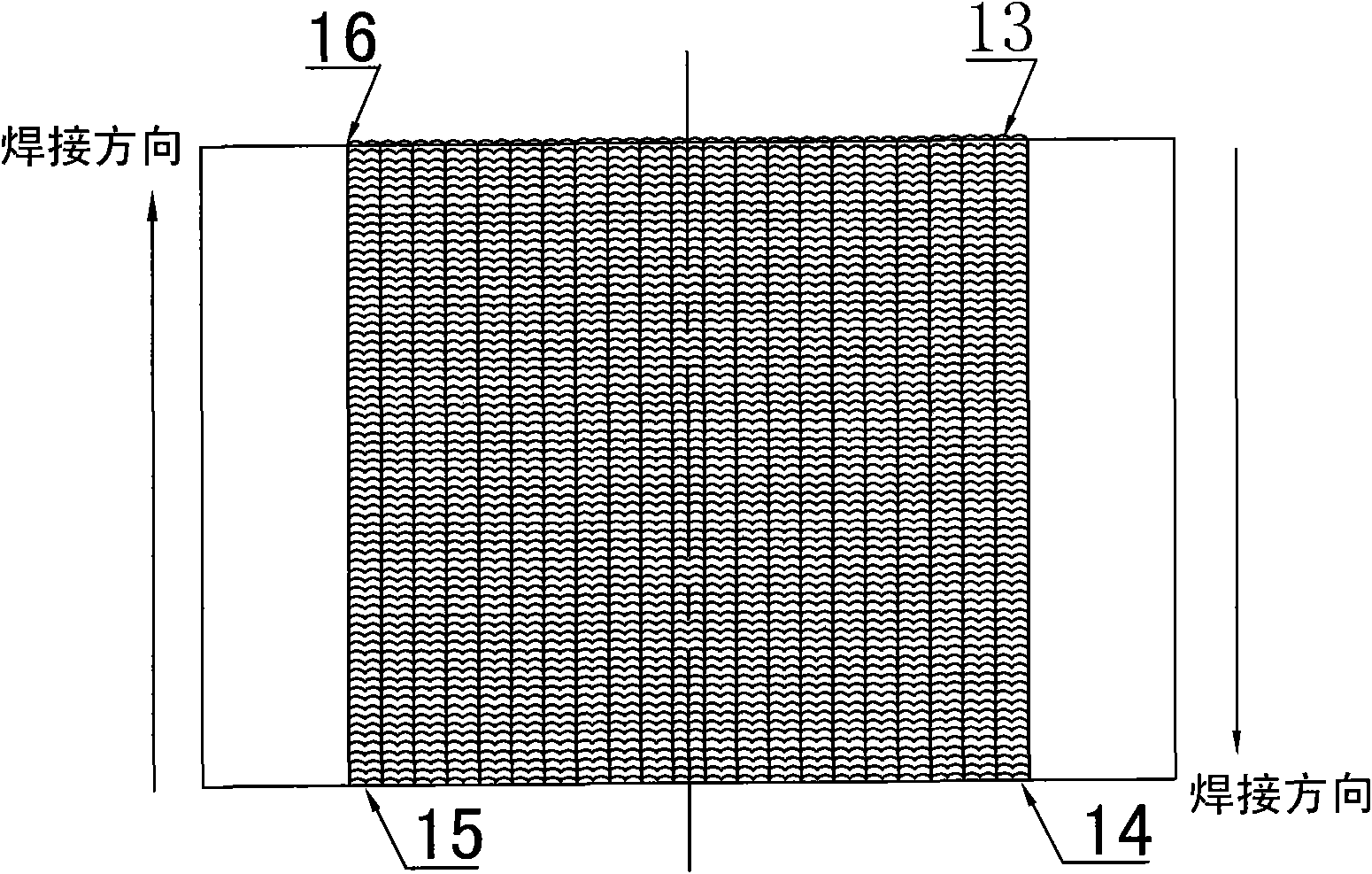

[0037] In order to reduce the stress and deformation generated during the welding process and reduce the influence of welding deformation on the mechanical properties of the welded metal deposition, the surfacing welding is carried out by symmetrical welding on both sides of the test plate, that is, the first layer of weld bead 1 is welded on the f...

Embodiment 2

[0053] Step 1-3: same as embodiment 1.

[0054] Step 4: In order to ensure that the prepared sample can fully reflect the performance of the welding consumable itself, each side of the surfacing welding bead generally maintains 10 layers. The thickness of the welding consumable deposited metal of the surfacing welding is 21mm, the width is 165mm, and the length is 185mm.

[0055] All the other are with embodiment 1.

Embodiment 3

[0057] Step 1-3: same as embodiment 1.

[0058] Step 4: In order to ensure that the prepared samples can fully reflect the performance of the welding consumable itself, each side of the surfacing welding bead generally maintains 12 layers. The thickness of the welding consumable deposited metal of the surfacing welding is 22mm, the width is 170mm, and the length is 190mm.

[0059] All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com