Production technology of high purity phosgene with low hydrogen chloride content

A production process, hydrogen chloride technology, applied in the direction of carbonyl chloride, etc., can solve problems such as hydrogen chloride condensation, achieve the effect of simplifying the process and reducing manufacturing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

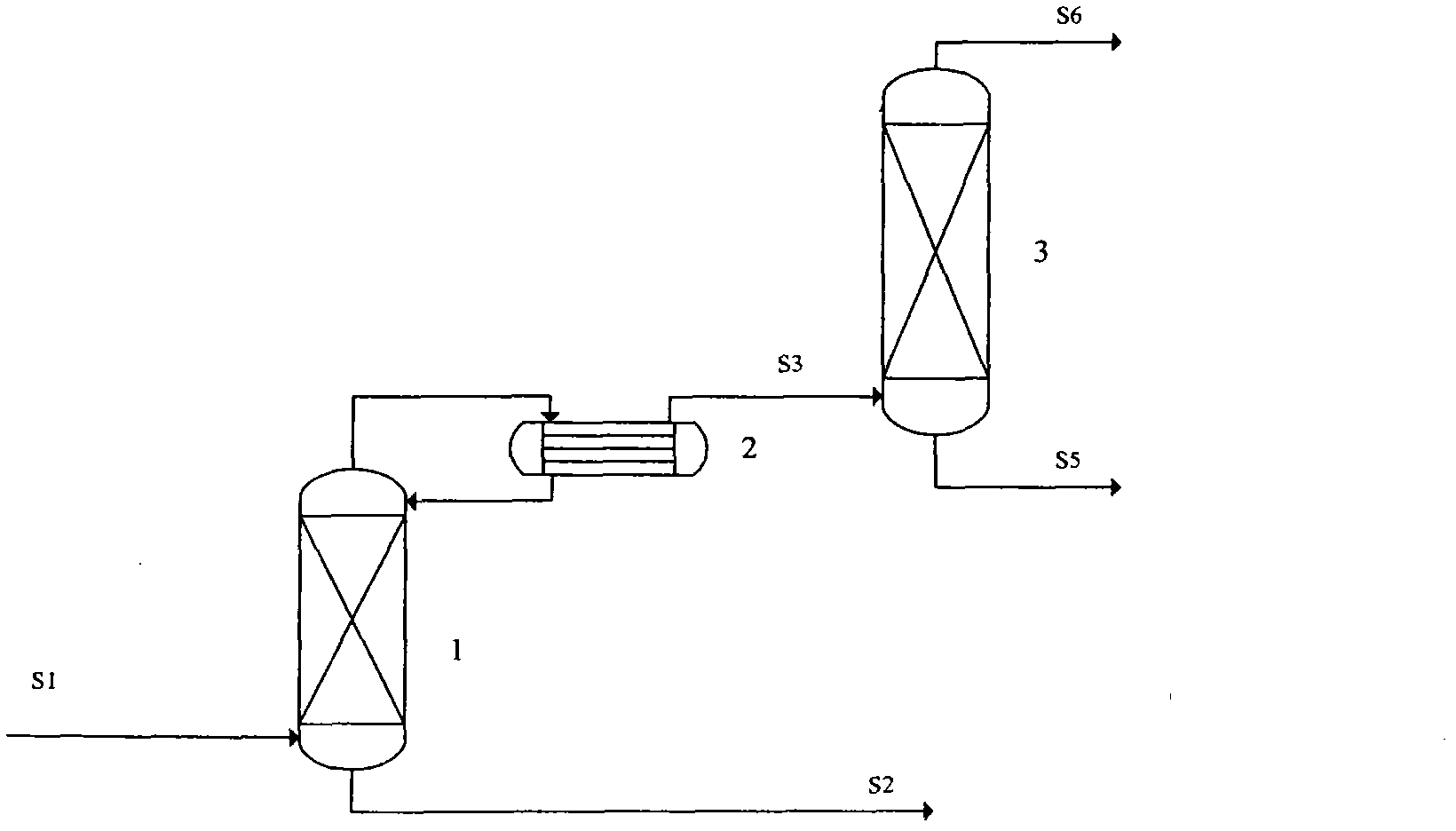

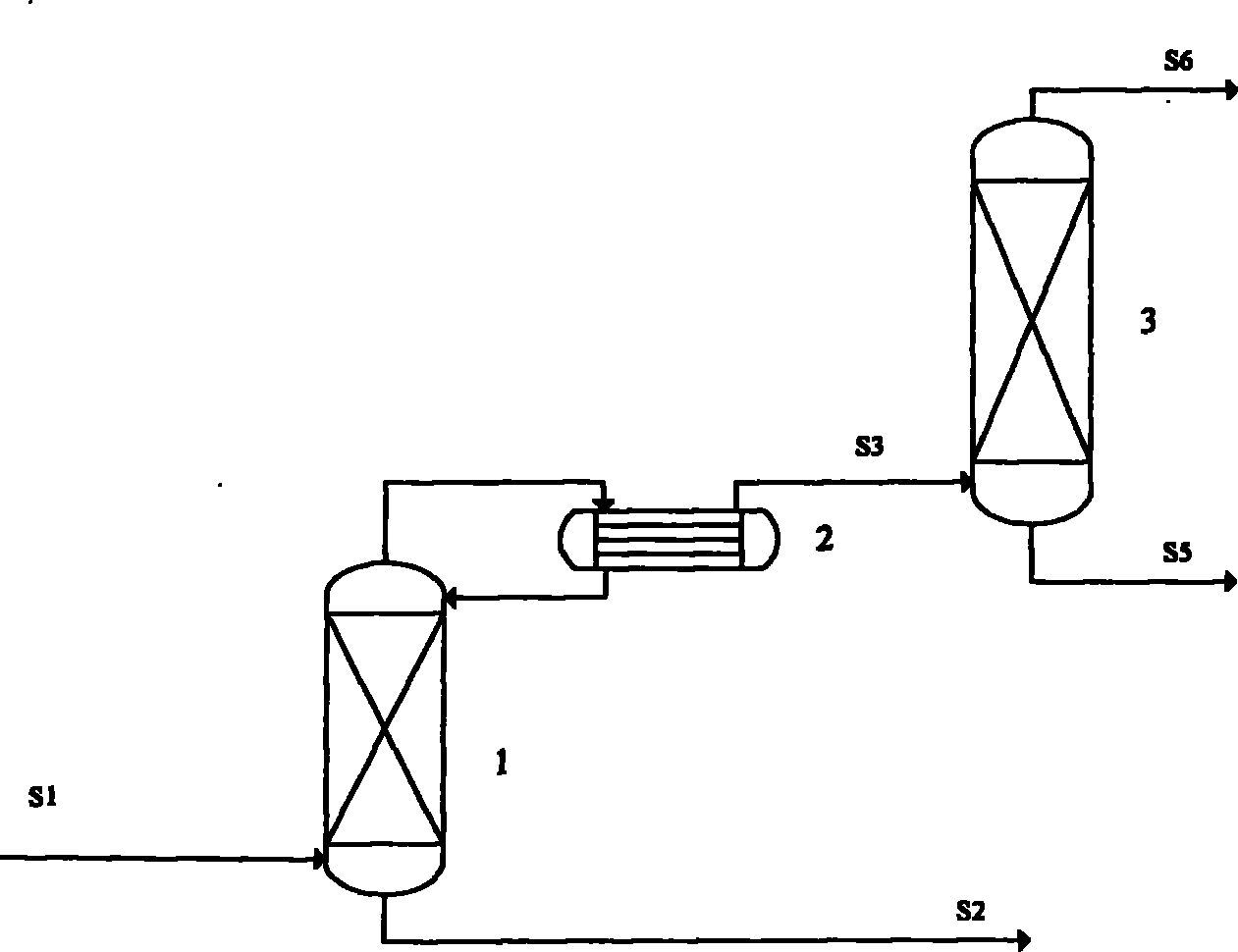

[0025] The rectification tower 1 is a packed tower with three theoretical plates. The phosgene-rich mixed gas S1 from the phosgene synthesizer has a flow rate of 50kg / h, a temperature of 65°C, and a pressure of 0.5MPa. The composition is: 97.16% phosgene, 2.23% carbon monoxide, 0.21% hydrogen chloride, and 0.21% nitrogen , 0.14% of carbon dioxide and 0.05% of other inert gases, S1 enters from the third plate of rectification tower 1, the operating pressure of rectification tower 1 is 0.45MPa, and the reflux ratio is 20. The phosgene product S2 is obtained at the bottom of the rectifying tower 1 .

[0026] There is a partial condenser 2 on the top of the rectification tower 1, and the liquid phase provides reflux. The mixed gas S3 passes through the absorption tower 3. The absorption tower 3 is a packed tower with 3 theoretical plates, and the phosgene in it is further recovered with toluene. The absorption tower The exhaust S6 at the top of the tower 3 is sent to tail gas tre...

Embodiment 2

[0033] The rectification tower 1 is a packed tower with 5 theoretical plates. The phosgene-rich mixed gas S1 flow rate from the phosgene synthesizer is 50kg / h, the temperature is 65°C, and the pressure is 0.5MPa, and the composition is phosgene 97.16%, carbon monoxide 2.23%, hydrogen chloride 0.21%, nitrogen 0.21%, Carbon dioxide 0.14% and other inert gases 0.05%, S1 enters from the 5th plate of the rectification tower 1, the operating pressure of the rectification tower 1 tower is 0.45MPa, and the reflux ratio is 24. The phosgene product S2 is obtained at the bottom of the rectifying tower 1 .

[0034] There is a fractional condenser 2 at the top of rectification tower 1, and the liquid phase provides reflux, and the mixed gas S3 passes through absorption tower 3. The exhaust gas S6 is sent to tail gas treatment, and the phosgene solution S5 recovered from the bottom of the absorption tower 3 can be further purified or destroyed according to the needs of the process. The pr...

Embodiment 3

[0041] The rectification tower 1 is a packed tower with 10 theoretical plates. The phosgene-rich mixed gas S1 from the phosgene synthesizer has a flow rate of 50kg / h, a temperature of 65°C, and a pressure of 0.5MPa. The composition is: 97.16% phosgene, 2.23% carbon monoxide, 0.21% hydrogen chloride, and 0.21% nitrogen , carbon dioxide 0.14% and other inert gases 0.05%, S1 enters from the 10th plate of the rectification tower 1, the operating pressure of the rectification tower 1 tower is 0.45MPa, and the reflux ratio is 18. The phosgene product S2 is obtained at the bottom of the rectifying tower 1 .

[0042] There is a partial condenser 2 on the top of the rectification tower 1, and the liquid phase provides reflux. The mixed gas S3 passes through the absorption tower 3. The theoretical plate number of the absorption tower 3 is 10, and the phosgene therein is further recovered with dichloromethane. The absorption tower 3 The exhaust S6 at the top is sent to tail gas treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com