Nano high-efficiency composite blockage removing liquid

A high-efficiency, plugging-removing technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of short validity period, lower injection rate, low incremental injection volume, etc., to achieve enhanced oil recovery and long unblocked time , significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: the formula of the plug-removing liquid adopted is as follows: it is made up of the following components by weight percentage:

[0021] Sodium hypophosphite 8%, organic polyphosphorus carboxylic acid 0.8%, potassium persulfate 1.5%, blue 826 synergist 5%, potassium dichromate 7%, sodium molybdate 9%, iron ion stabilizer 10%, water 58.7%.

[0022] The medicaments of the above-mentioned components are miscible with water at room temperature and then stirred evenly.

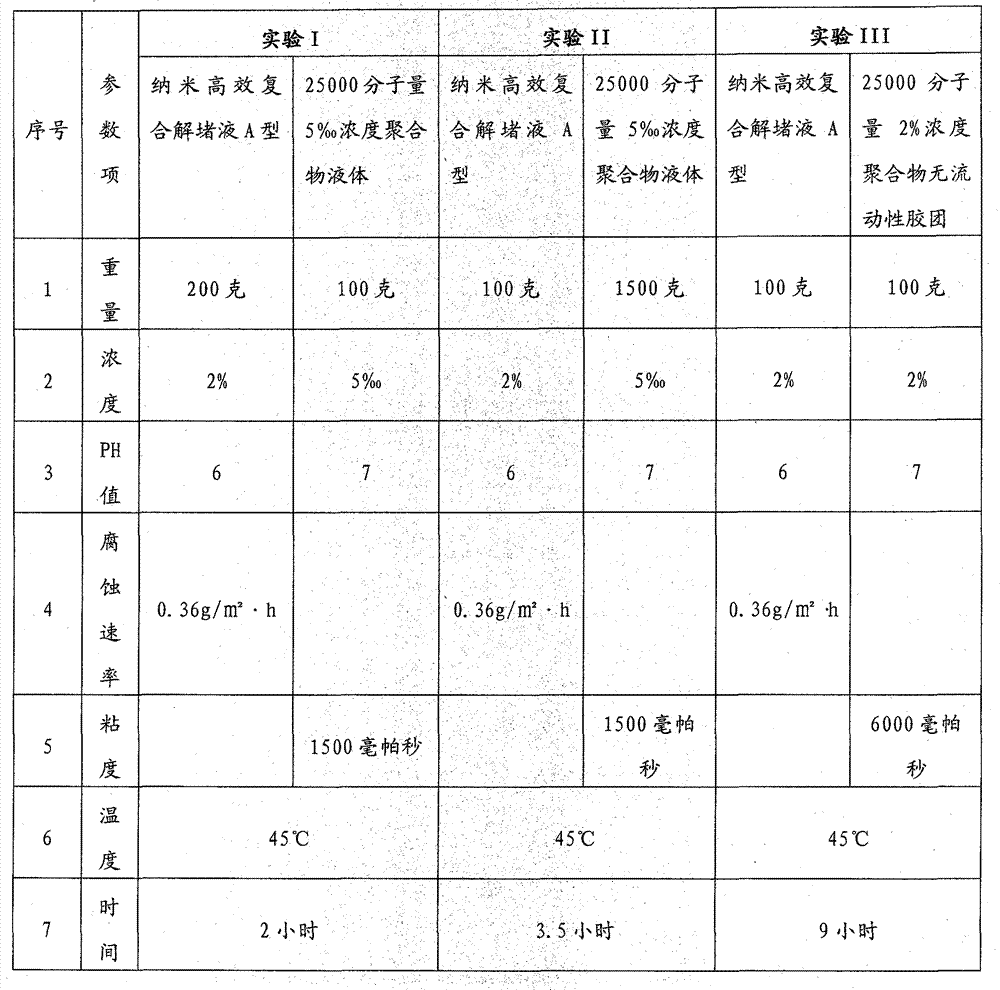

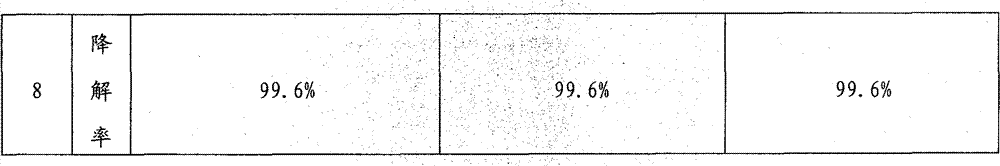

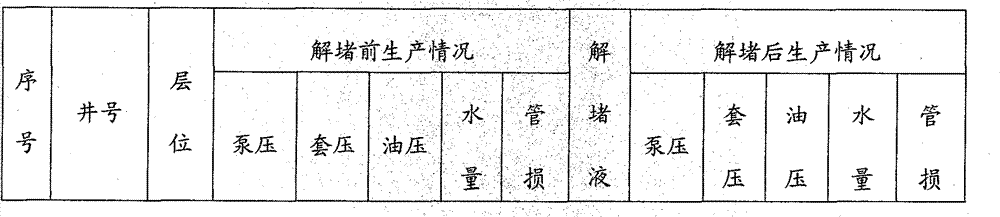

[0023] The use effect of the formula in this example in oil and water wells, refer to the following table 2:

[0024] Table 2. The use effect of embodiment 1:

[0025]

[0026]

[0027] It can be seen from Table 2 that the pressure and water volume indicators are very different before and after unblocking, which proves that this formula has a good effect on unblocking.

Embodiment 2

[0028] Embodiment 2: the prescription of the plug-removing liquid that adopts is as follows: be made up of the component of following percentage by weight:

[0029] Sodium hypophosphite 10%, organic polyphosphorus carboxylic acid 1%, potassium persulfate 2%, blue 826 synergist 4%, potassium dichromate 8%, sodium molybdate 10%, iron ion stabilizer 12%, water 53%. The medicaments of the above-mentioned components are miscible with water at room temperature and then stirred evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com