White LED chip and preparation method thereof

A LED chip and white light technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of phosphor degradation, high cost, unstable color temperature, etc., and achieve the effect of improving brightness, stability and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

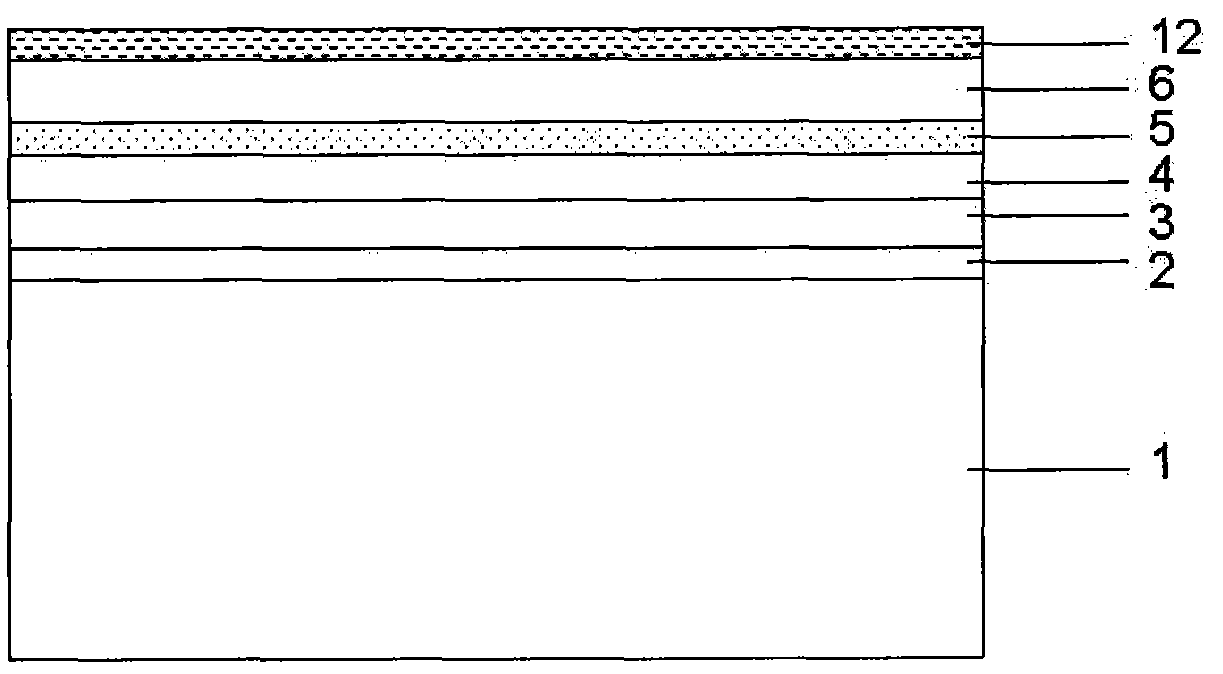

[0022] According to the method of the present invention to prepare the specific steps of the white LED chip process as follows:

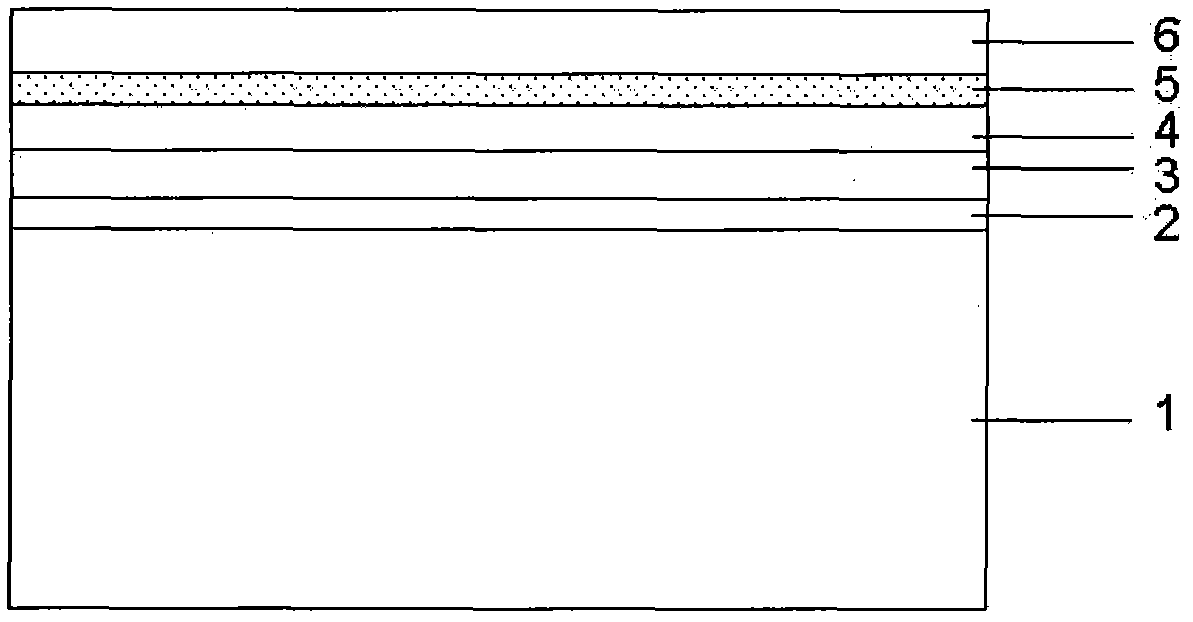

[0023] 1. Prepare the vertical structure blue LED chip of the SiC substrate: the buffer layer 2, the non-doped GaN layer 3, and the N-type GaN layer are sequentially grown on the SiC substrate 1 by conventional MOCVD (metal organic compound chemical vapor deposition) process 4. Active region 5 and P-type GaN layer 6 . The structure of the prepared vertical GaN-based blue LED chip is as follows figure 1 shown.

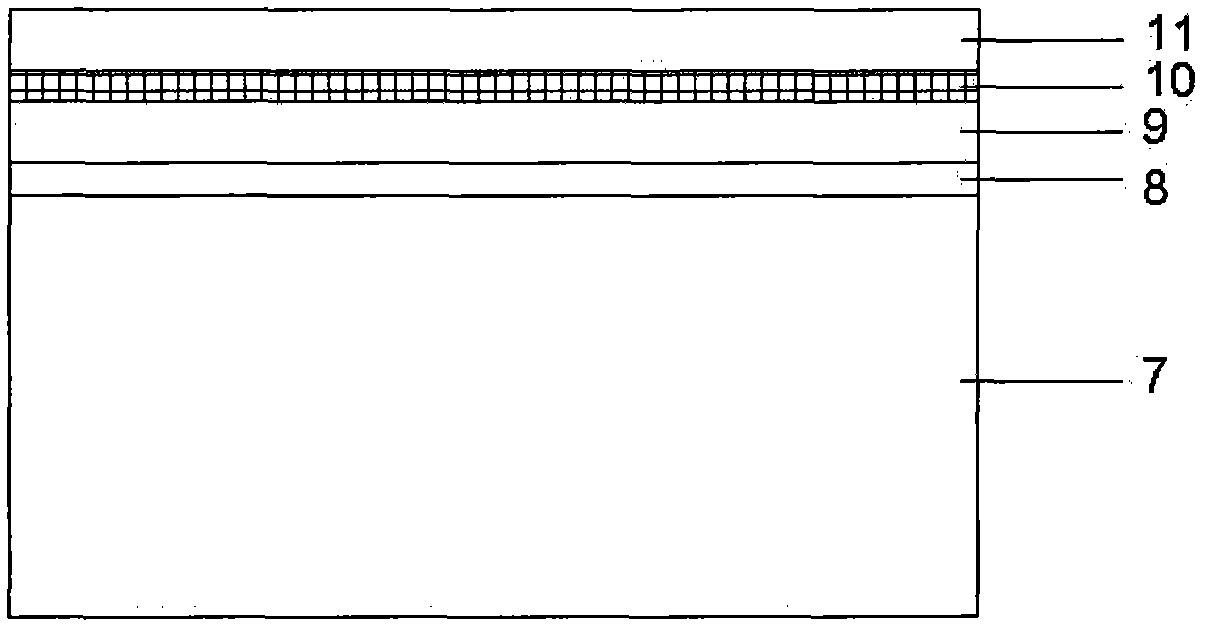

[0024] 2. Preparation of AlGaInP-based yellow LED chip: using conventional MOCVD (metal organic compound chemical vapor deposition) process to epitaxially grow buffer layer 8, P-type confinement layer 9, active region 10 and N on P-type GaAs substrate 7 in sequence type confinement layer 11. The structure of the prepared vertical GaN-based blue LED chip is as follows figure 2 shown. The substrate material of the blue LED chip can also u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com