Preparation process for preparing photocatalyst from blast furnace slag serving as raw material

A technology of photocatalyst and preparation process, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., which can solve the problems of long preparation time, unfavorable clean production, and unguaranteed quality of hydrothermal reaction precursors and other problems, to achieve the effect of improving photocatalytic activity, improving photocatalytic oxidation efficiency, and avoiding the problem of yellow smog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

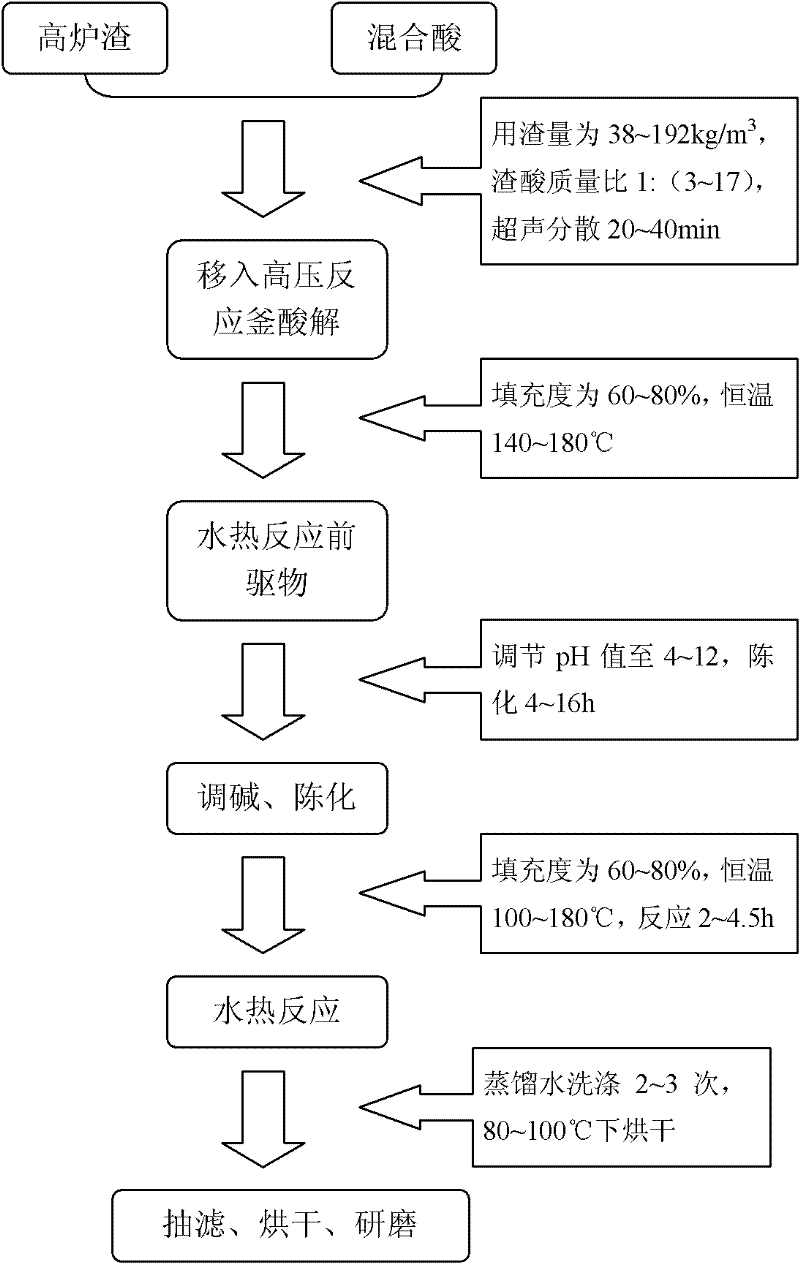

Method used

Image

Examples

Embodiment 1

[0018] Main components of blast furnace slag: SiO 2 5.21wt%, Al 2 o 3 7wt%, Fe 2 o 3 24wt%, CaO 18.2wt%, MgO 9.75wt%, Co 0.008wt%, Cr 0.20wt%, Cu 0.001wt%, V 0.23wt%, W 0.009wt%, P 1wt% , S is 0.003wt%, and the balance is unavoidable impurities.

[0019] Grind the blast furnace slag of the above ingredients to below 200 mesh, mix it with mixed acid (the molar ratio of sulfuric acid and nitric acid is 1:1) at a mass ratio of 1:17, ultrasonically disperse for 30 minutes, and then move it into a high-pressure reactor. The filling degree is 60%, acid hydrolysis at a constant temperature of 180°C for 10 hours, cooled to room temperature, standing still, taking out all the supernatant and the bottom colloid as the precursor of the hydrothermal reaction;

[0020] Adjust the pH value of the hydrothermal reaction precursor to 4 with sodium hydroxide solution, stir evenly, then age for 6 hours, move it into a high-pressure reactor with a filling degree of 80%, control the temperatu...

Embodiment 2

[0024] Main components of blast furnace slag: SiO 2 11.31wt%, Al 2 o 3 0.8wt%, Fe 2 o 3 28.6wt%, CaO 30.9wt%, MgO 18.55wt%, TiO 2 is 0.95wt%, Co is 0.005wt%, Cr is 0.06wt%, Cu is 0.005wt%, V is 0.005wt%, W is 0.005wt%, P is 1.34wt%, S is 0.05wt%, and the balance is unavoidable impurities.

[0025]Grind the blast furnace slag of the above ingredients to below 200 meshes, mix it with mixed acid (the molar ratio of sulfuric acid and nitric acid is 1:0.4) at a mass ratio of 1:5, ultrasonically disperse it for 20 minutes, and then move it into a high-pressure reactor. The filling degree is 70%, acid hydrolyzed at a constant temperature of 160°C for 8 hours, cooled to room temperature, left standing, and the supernatant and the bottom colloid are taken as the precursors of the hydrothermal reaction;

[0026] Adjust the pH value of the hydrothermal reaction precursor to 12 with sodium hydroxide solution, stir evenly, then age for 16 hours, move it into a high-pressure reactor w...

Embodiment 3

[0028] Main components of blast furnace slag: SiO 2 27.08wt%, Al 2 o 3 21.9wt%, Fe 2 o 3 0.5wt%, CaO 40wt%, MgO 3.38wt%, TiO 2 is 0.42wt%, Co is 0.008wt%, Cr is 0.43wt%, Cu is 0.009wt%, V is 0.10wt%, W is 0.002wt%, P is 0.002wt%, S is 0.27wt%, and the balance is unavoidable impurities.

[0029] Grind the blast furnace slag of the above ingredients to below 200 mesh, mix it with mixed acid (the molar ratio of sulfuric acid and nitric acid is 1:2) at a mass ratio of 1:3, ultrasonically disperse it for 20 minutes, and then move it into a high-pressure reactor. The filling degree is 70%, acid hydrolyzed at a constant temperature of 160°C for 8 hours, cooled to room temperature, left standing, and the supernatant and the bottom colloid are taken as the precursors of the hydrothermal reaction;

[0030] Adjust the pH value of the hydrothermal reaction precursor to 12 with sodium hydroxide solution, stir evenly, then age for 16 hours, move it into a high-pressure reactor with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com