Amphiphilic porous hollow carbon microsphere as well as preparation method and application thereof

A technology of carbon microspheres and amphiphilicity, which is applied in the field of amphiphilic porous hollow carbon microspheres and their preparation and application, which can solve the problems of increased cost and complicated preparation process, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

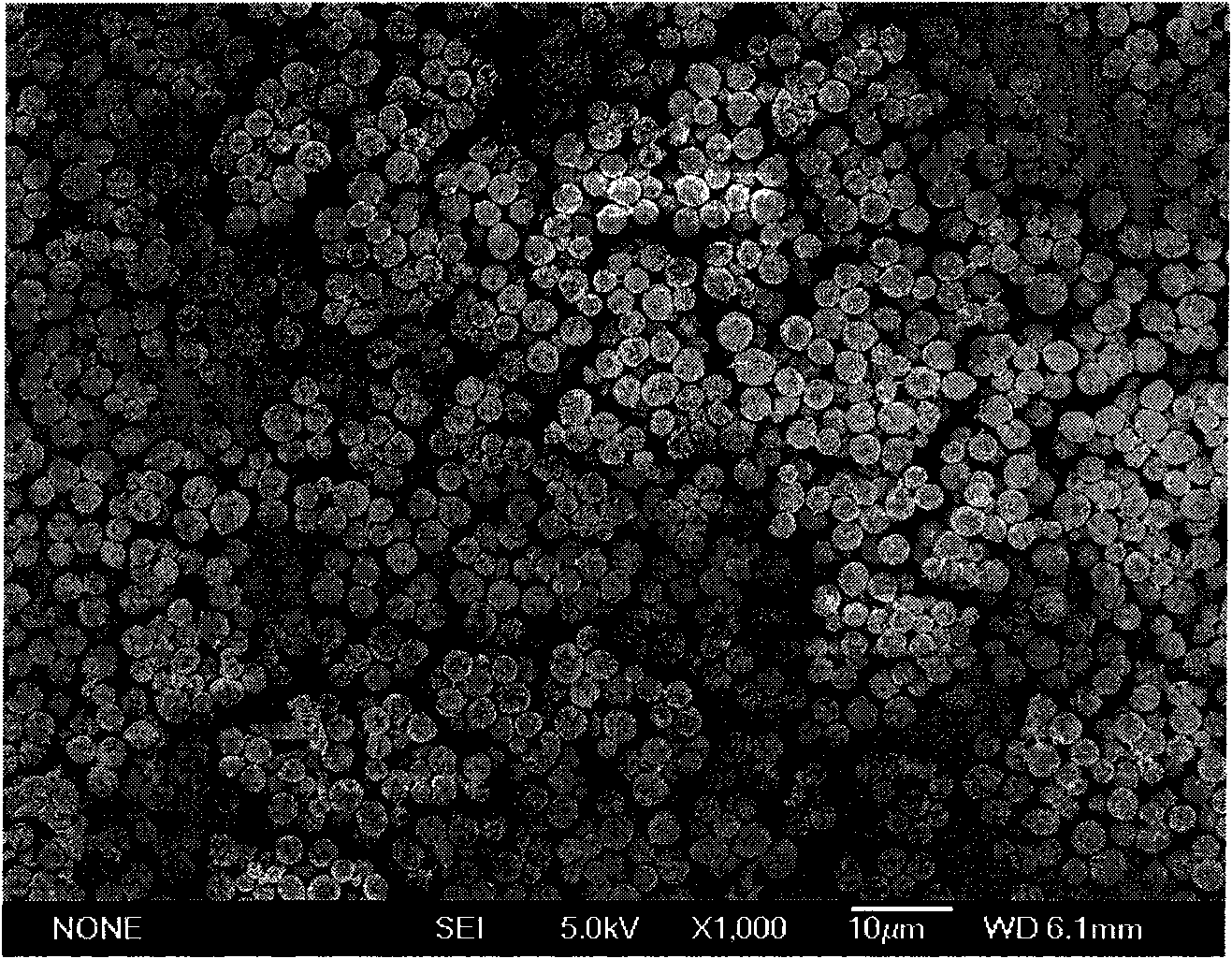

[0031] Embodiment 1, the preparation of amphiphilic mesoporous hollow carbon microsphere a

[0032] Weigh 1 g of Saccharomyces cerevisiae (manufacturer is Angel Yeast Co., Ltd., trade name is high temperature resistant brewing high-activity dry yeast, catalog number 80000012), and disperse it in 100 ml of 0.1 mol / L butanediol aldehyde, and then transferred to the reaction kettle and placed in a thermostat for 14 hours at 180 ° C, the obtained precipitate was washed with deionized water, and dried at 20 ° C for 24 hours, after drying, the amphiphilic porous hollow carbon was obtained Microspheres.

[0033] Observation of amphiphilic porous hollow carbon microspheres by scanning electron microscope. The pore size distribution on the shell of amphiphilic porous hollow carbon microspheres was determined by nitrogen adsorption method. The infrared characterization of the surface functional groups of amphiphilic porous hollow carbon microspheres was carried out by Fourier transfor...

Embodiment 2

[0035] Example 2, Preparation of Amphiphilic Mesoporous Hollow Carbon Microspheres b

[0036] The preparation method is basically the same as in Example 1, except that the surface protection agent used is glutaraldehyde, the concentration is 0.05mol / L, the dosage of yeast is 5g, and the rest of the steps are the same as in Example 1.

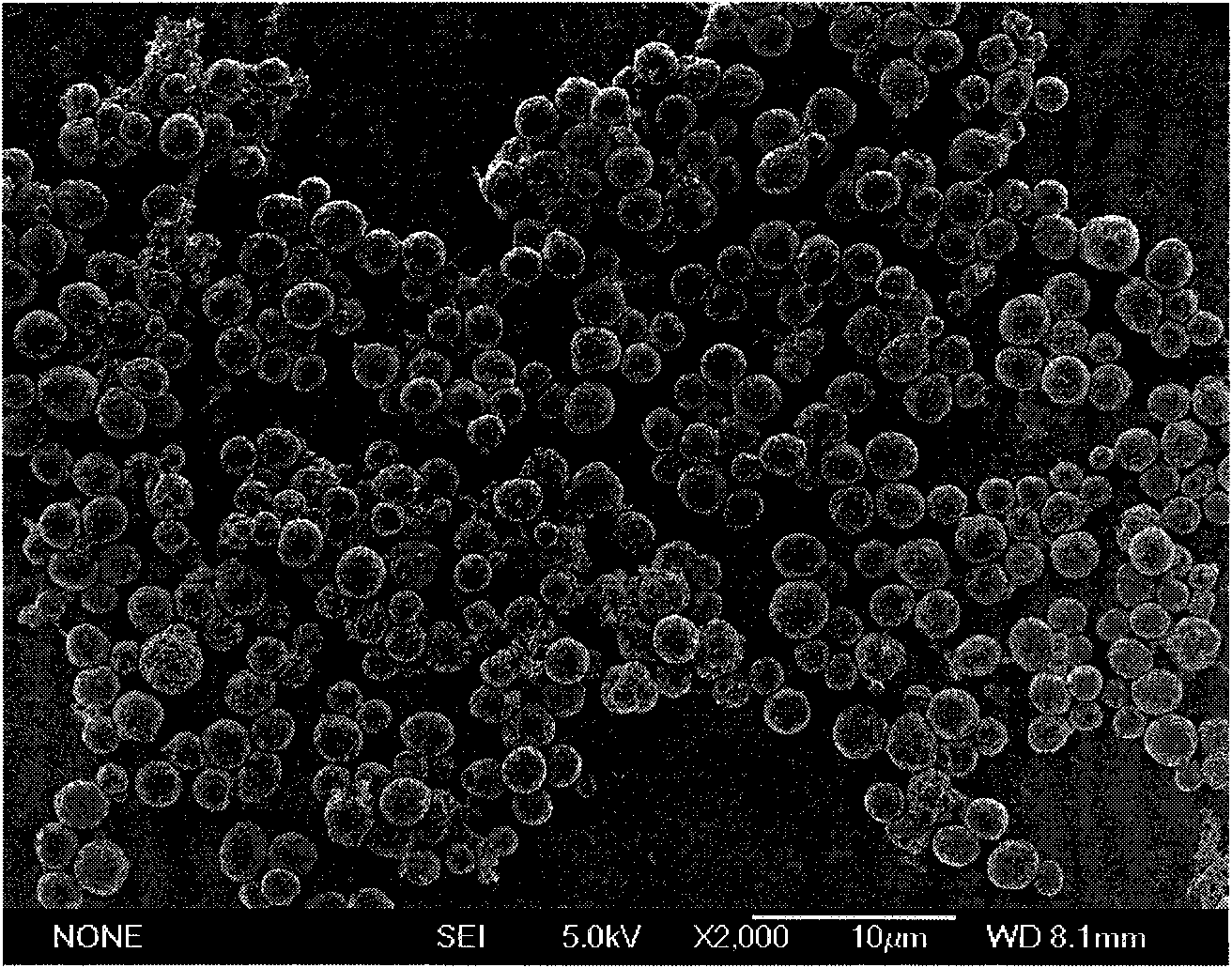

[0037] The structure of the product under the scanning electron microscope is as follows figure 2 As shown, the prepared hollow carbon microspheres are spherical with a diameter of 2-4 microns. Its nitrogen adsorption-desorption isotherm and pore size distribution diagram are shown in Figure 6 As shown, according to the nitrogen adsorption-desorption isotherm, the average pore diameter on the spherical shell is 43.5nm. Its infrared characterization result is similar to Example 1.

Embodiment 3

[0038] Example 3, Preparation of Amphiphilic Macroporous Hollow Carbon Microspheres

[0039]The preparation method is basically the same as in Example 1, except that the surface protection agent used is adipaldehyde, the concentration is 0.01mol / L, the dosage of yeast is 20g, and the rest of the steps are the same as in Example 1.

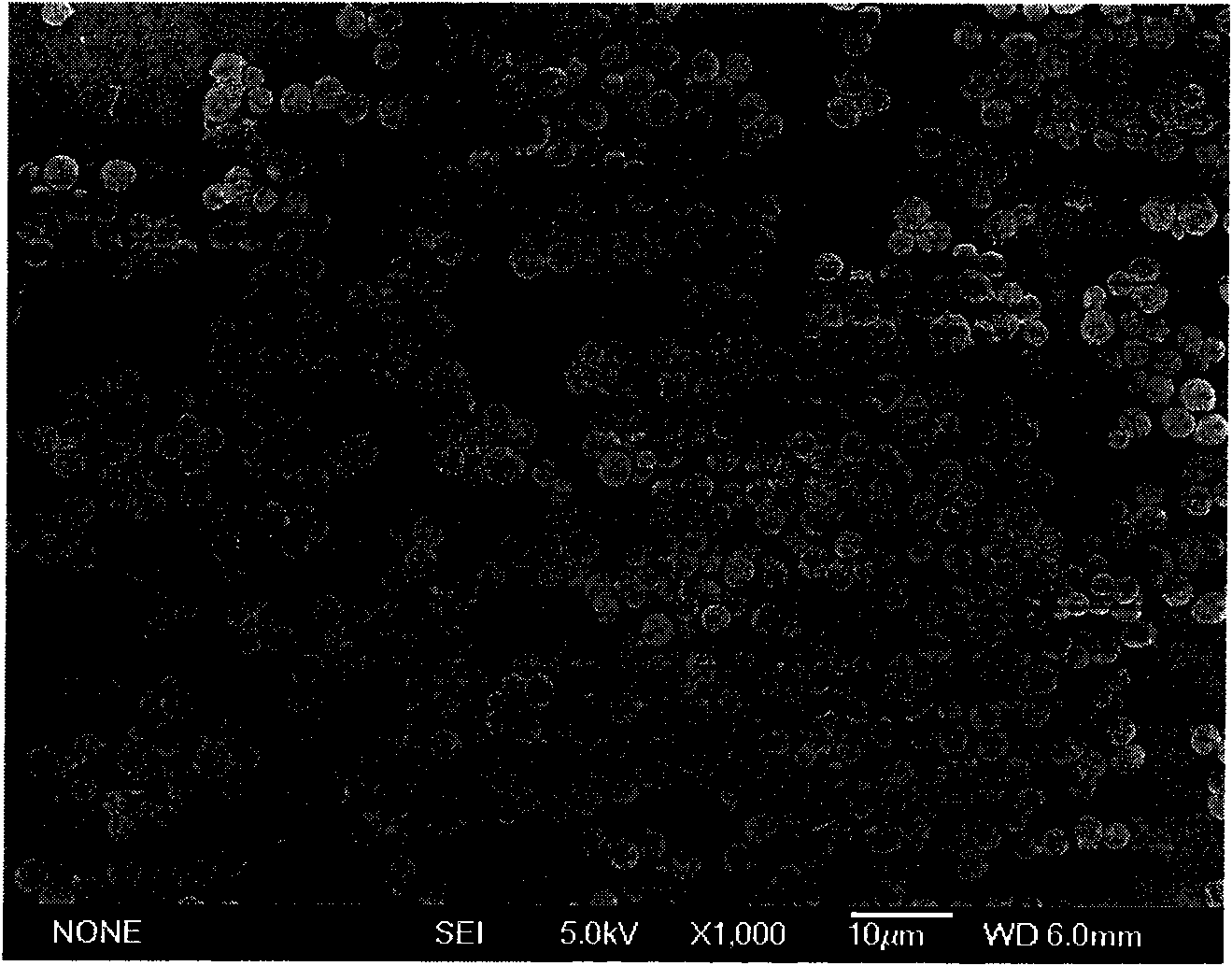

[0040] The structure of the product under the scanning electron microscope is as follows image 3 As shown, the prepared hollow carbon microspheres are also spherical with a diameter of 2-4 microns. Its nitrogen adsorption-desorption isotherm and pore size distribution diagram are shown in Figure 7 As shown, according to the nitrogen adsorption-desorption isotherm, the average pore diameter on the spherical shell is 50.2nm, and the infrared characterization result is similar to that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com