Natural gas separation device

A separation device, natural gas technology, applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of difficult separation of sulfides, poor separation effect, and huge investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiment of the present invention discloses a natural gas separation device. The natural gas separation device can effectively separate water vapor in natural gas before liquefying natural gas, especially impurities such as sulfur and carbon. The device not only has a simple structure and low cost, but also has Good separation effect.

[0020] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution provided by the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

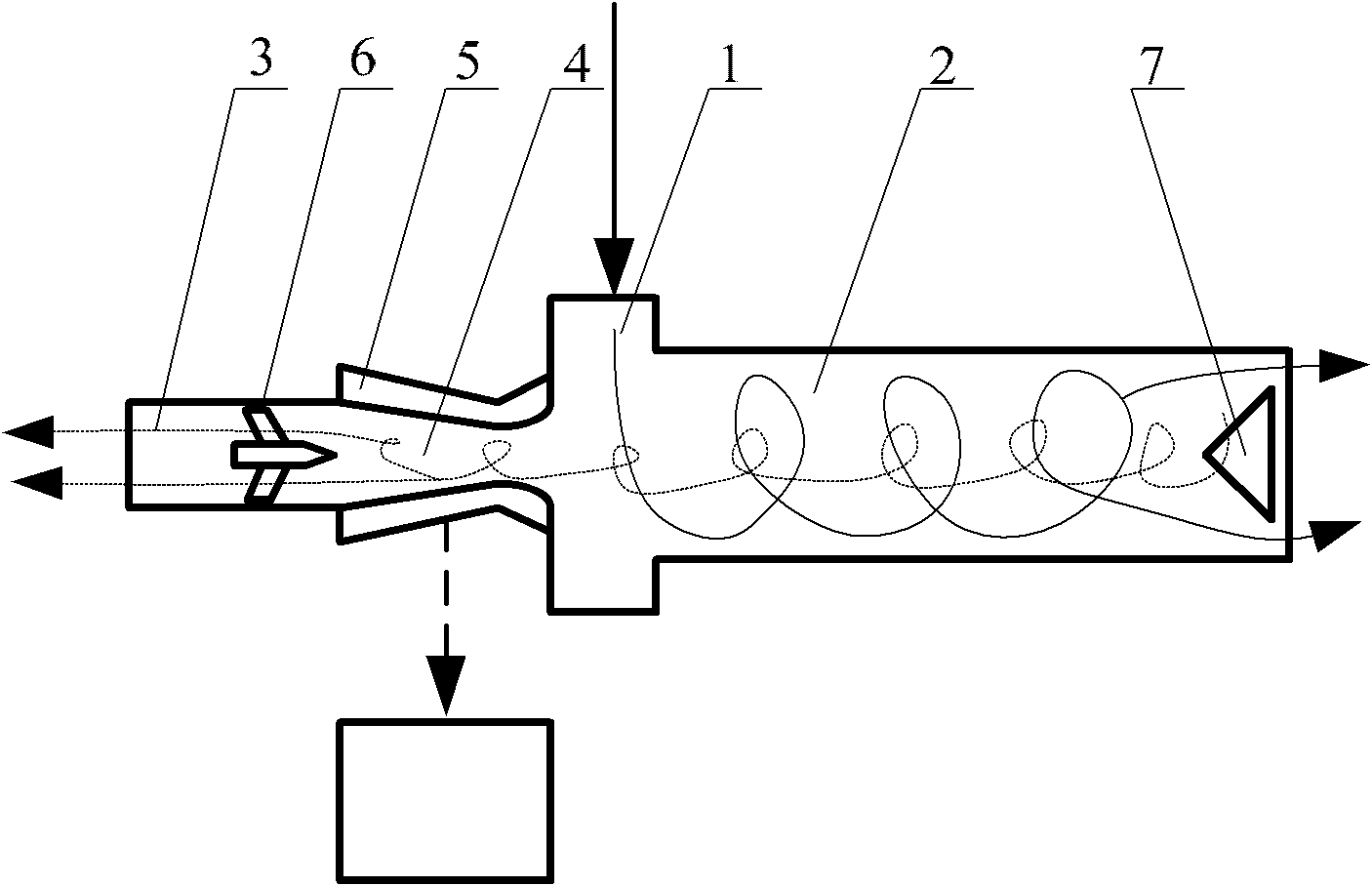

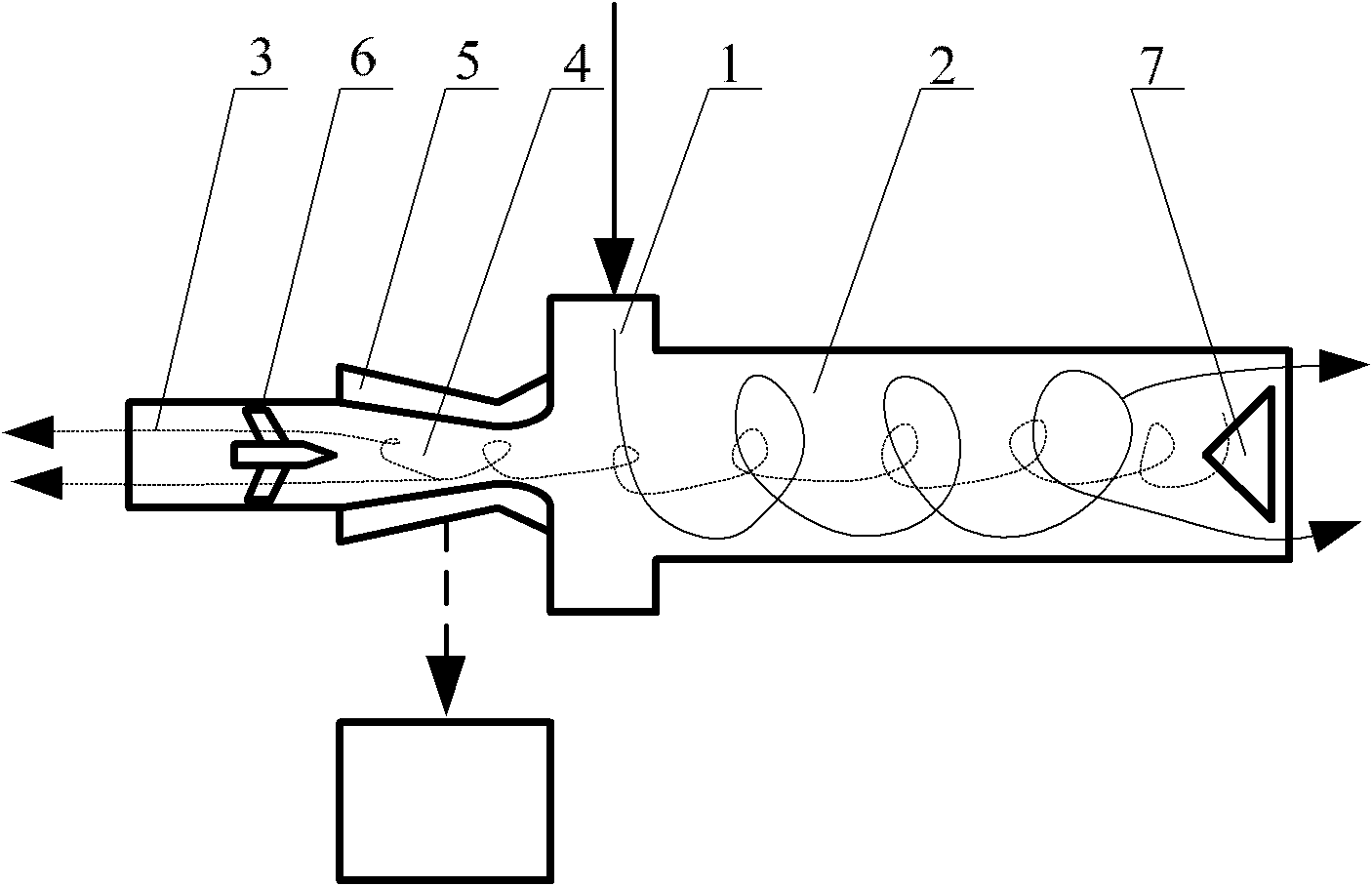

[0021] Please refer to figure 1 , figure 1 Schematic diagram of the structure of the natural gas separation device provided by the present invention.

[0022] The natural gas separation device provided by the present invention comprises a vortex tube 1, a hot end tube 2 and a cold end tube 3, the air inlet of the hot end tube 2 communicates with the hot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com