Culture method and applications of Ganoderma weberianum mycelial pellets

A technology of ganoderma lucidum mycelium and cultivation method, which is applied in the direction of chemical instruments and methods, fungi, water/sludge/sewage treatment, etc. It can solve the problems of low chromaticity removal efficiency and long reaction time, and achieve convenient operation Extensive, low cost, high decolorization degradation activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

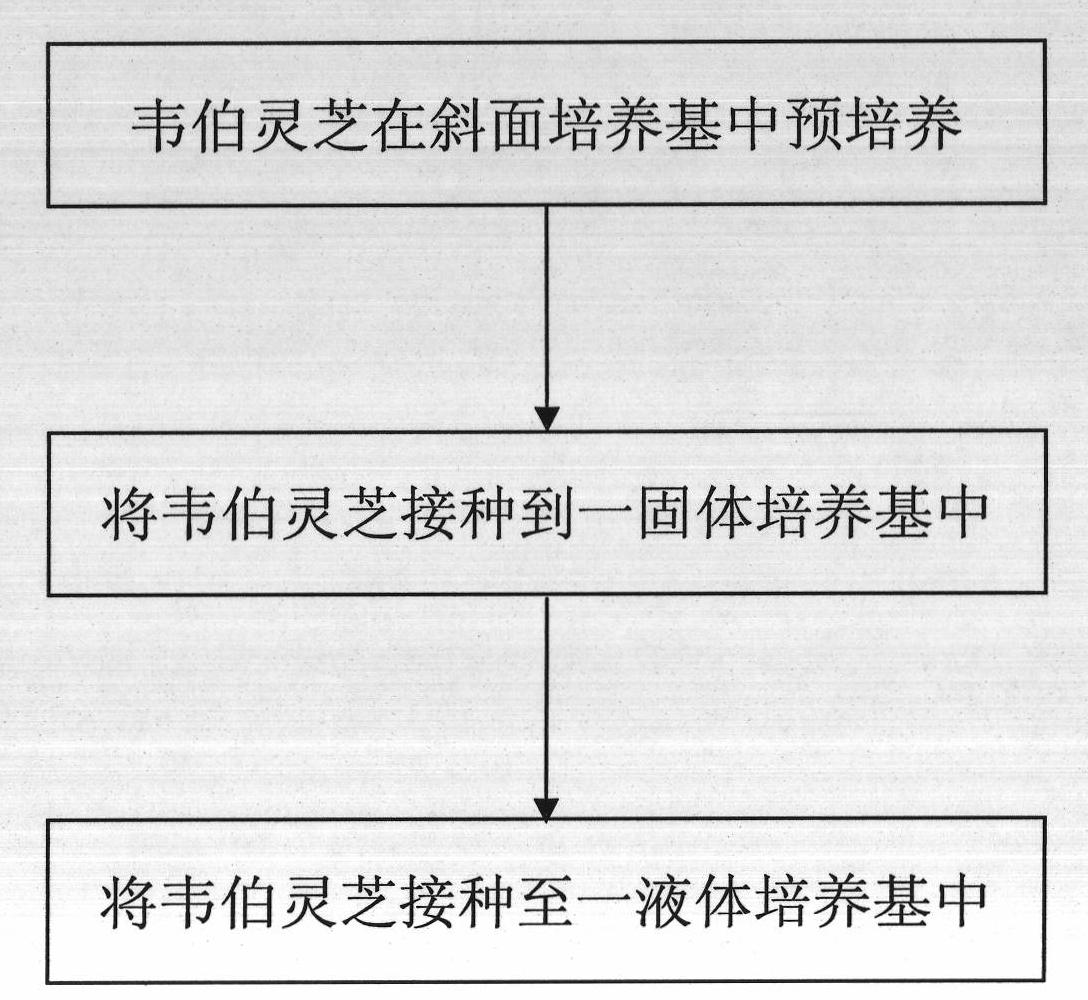

[0038] 1. Preparation of Weber Ganoderma lucidum mycelium balls

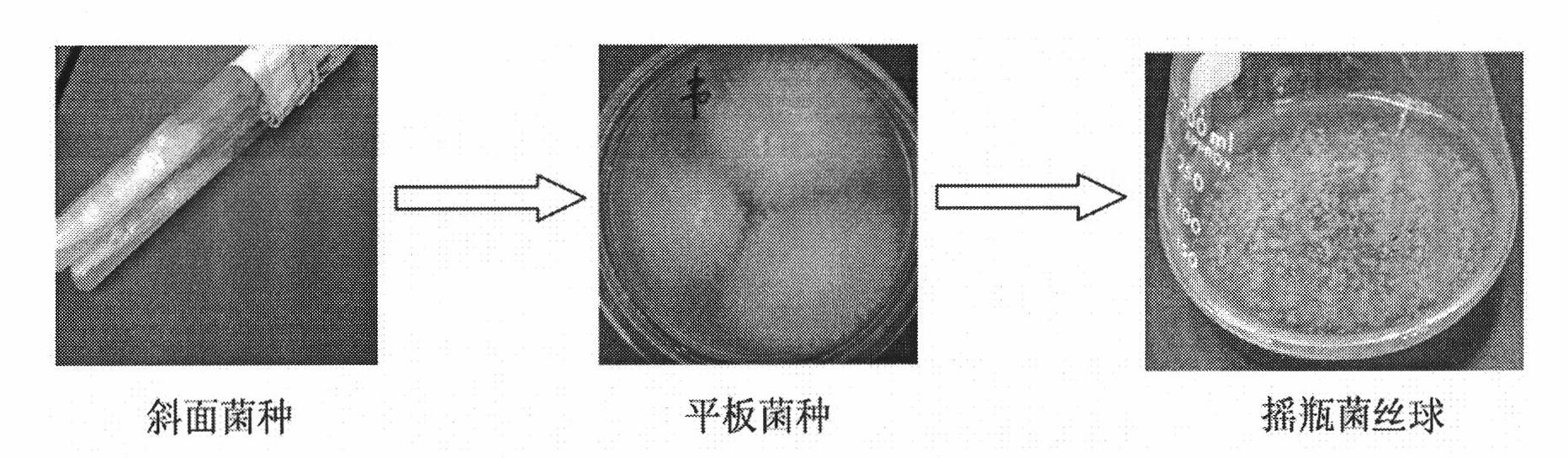

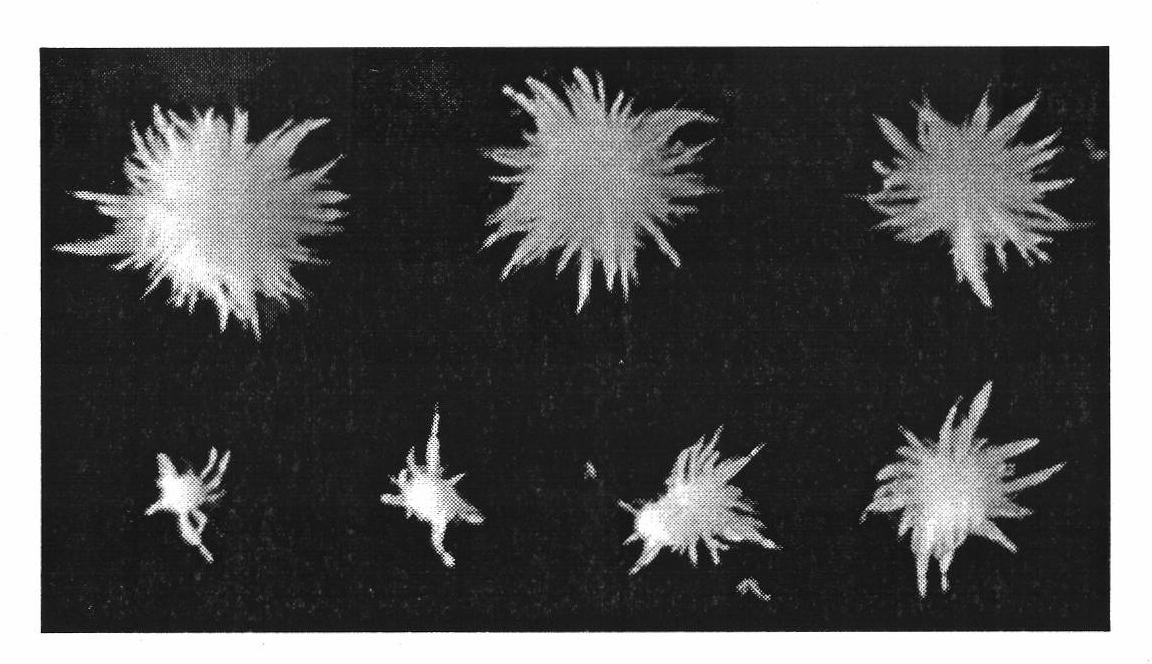

[0039] Under sterile conditions, use an inoculation loop to dig out the mycelia from the slant strains and transfer them to the plate medium, and put them in an incubator at 25-32°C for 2-5 days to obtain activated strains such as figure 1 with figure 2 shown. Then under aseptic conditions, dig mycelium from the plate of activated strains, disperse evenly, add it to the liquid culture medium containing Weber Ganoderma lucidum mycelium balls, under the conditions of 25-32°C and 120-200 rpm Vibrating culture for 3-6 days can obtain Weber ganoderma mycelium balls. The optimum condition for the activation of strains is to culture in an incubator at 28°C for 4 days; the optimum condition for obtaining Weber's Ganoderma lucidum mycelium ball is to culture with shaking at 28°C and 160 rpm for 5 days. image 3 Shown are mycelial pellets of various sizes obtained using this method.

[0040] The medium formula used i...

Embodiment 1

[0050] Add indigo solution to the culture of Weber ganoderma lucidum hyphae bulbs obtained by the method of the present invention to make the concentration 20mg / L, and adjust the acidity and alkalinity of the solution to pH4, and cultivate it statically for 2 hours at 28°C, and the indigo The decolorization rate is 41% as Figure 4 shown.

Embodiment 2

[0052] Add indigo solution to the Weber ganoderma mycelium culture obtained by the method of the present invention to make the concentration 20mg / L, and adjust the acidity and alkalinity of the solution to pH4, shake at 28°C and 160 rpm After culturing for 2 hours, the decolorization rate of indigo is 88%. Figure 4 shown.

[0053] Comparing Examples 1 and 2, it can be seen that shaking culture is beneficial to decolorization, and shaking culture is used in the following examples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com