Alkaline earth metal saponification and extraction method of acidic extractant

An acid extraction agent and alkaline earth metal soap technology, which is applied in the field of hydrometallurgical extraction and separation, can solve the problems of environmental discharge, use of soluble chloride, complicated treatment of harmful waste water, etc., and achieves the effect of solving environmental pollution and avoiding pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

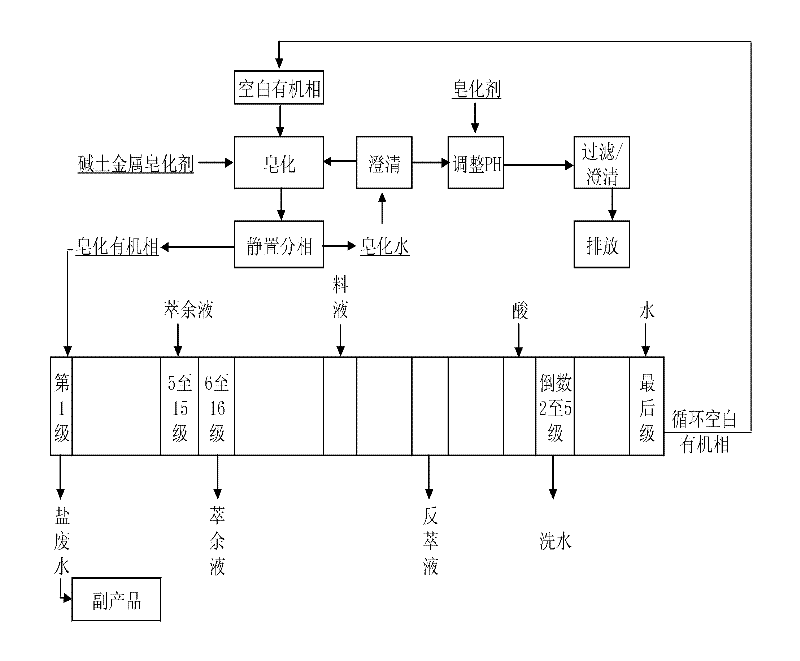

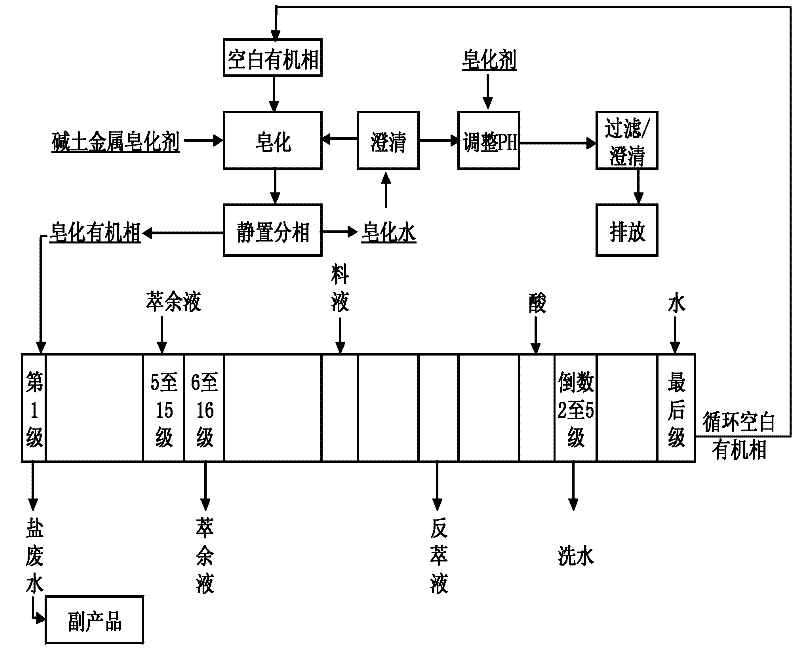

Image

Examples

Embodiment 1

[0024] Add 2 cubic meters of saponification water in the saponification pot, then add 8.0 cubic meters of P507 blank organic phase (P507 and kerosene weight ratio 1: 1), start stirring, add 240Kg calcium carbonate powder, stop stirring after continuing to stir for 70 minutes, and let stand for 120 Minutes, after confirming that the two-phase interface is clear, open the bottom valve of the saponification pot to discharge a small amount of residue and saponification water to the low-level wastewater tank to clarify and recover a small amount of organic phase; part of the clarified saponification wastewater is pumped into the saponification pot for recycling; the residue and another part of saponification The waste water is sent to another reaction pot, and calcium carbonate powder is added to adjust the pH to 6.5-7, and the clear liquid is discharged after filtration.

[0025] This calcium saponified organic phase is introduced into the first-stage mixing chamber of the 110-stag...

Embodiment 2

[0027] Add 900 liters of clarified saponification water in the saponification pot, then add 8.0 cubic P204 blank organic phase (P204 and kerosene weight ratio 1: 2), start stirring, add 40Kg magnesium hydroxide powder, stop stirring after continuing to stir for 20 minutes, static Set aside for 20 minutes, after confirming that the two-phase interface is clear, open the bottom valve of the saponification pot to discharge a small amount of residue and saponification water into the low-level waste water tank to clarify and recover a small amount of organic phase; part of the clarified saponification waste water is pumped into the saponification pot for recycling; the residue and other Part of the saponification wastewater is sent to another reaction pot, and calcium hydroxide is added to adjust the pH to 6.5-8, and the clear liquid is discharged after clarification.

[0028] The magnesium saponified organic phase is introduced into the mixing chamber of the first stage of the 40-s...

Embodiment 3

[0030] Add 1.2 cubic meters of clear saponified water into the saponification pot, and then add 8.0 cubic meters of C 272 Blank organic phase (weight ratio C272: thinner=2: 3, diluent is weight ratio sulfonated kerosene: isooctyl alcohol=8: 2), start stirring, add 100Kg calcium hydroxide powder, stop stirring after continuing to stir for 30 minutes , let it stand for 40 minutes, and after confirming that the two-phase interface is clear, open the bottom valve of the saponification pot to discharge a small amount of residue and saponification water into the low-level wastewater tank to clarify and recover a small amount of organic phase; part of the clarified saponification wastewater is pumped into the saponification pot for recycling; the residue And another part of saponification waste water is sent to another reaction pot, and calcium hydroxide powder is added to adjust the pH to 6.5-8, and the clear liquid is discharged after filtration.

[0031] This calcium saponified or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com