Washing machine adjusting heating power according to different input energies and use method

A heating power, washing machine technology, applied to other washing machines, washing machine control devices, applications, etc., can solve the problem of selecting a specific heating program for energy storage power supply, and achieve the effects of avoiding heat dissipation problems, preventing service life decline, and avoiding current fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

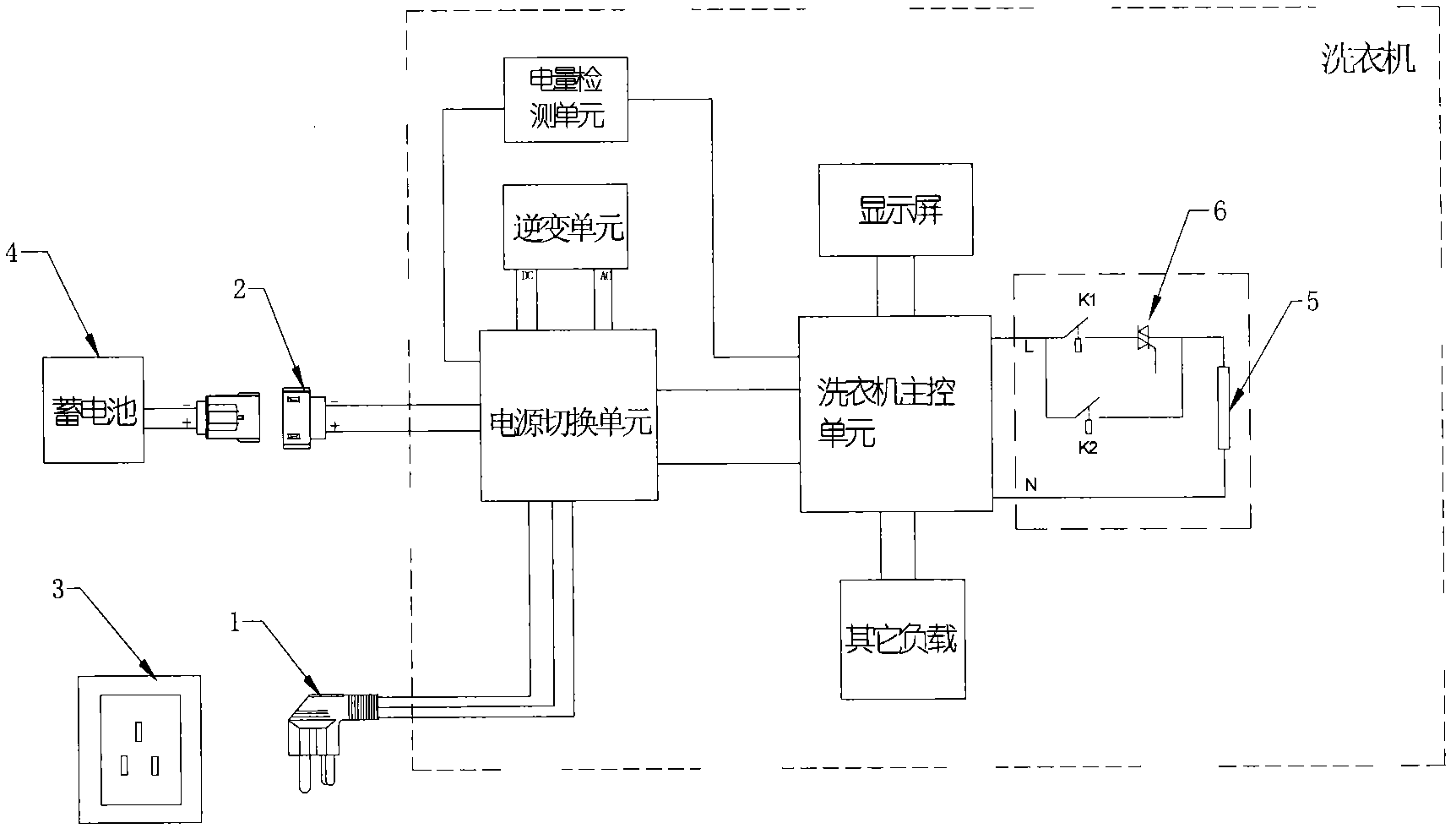

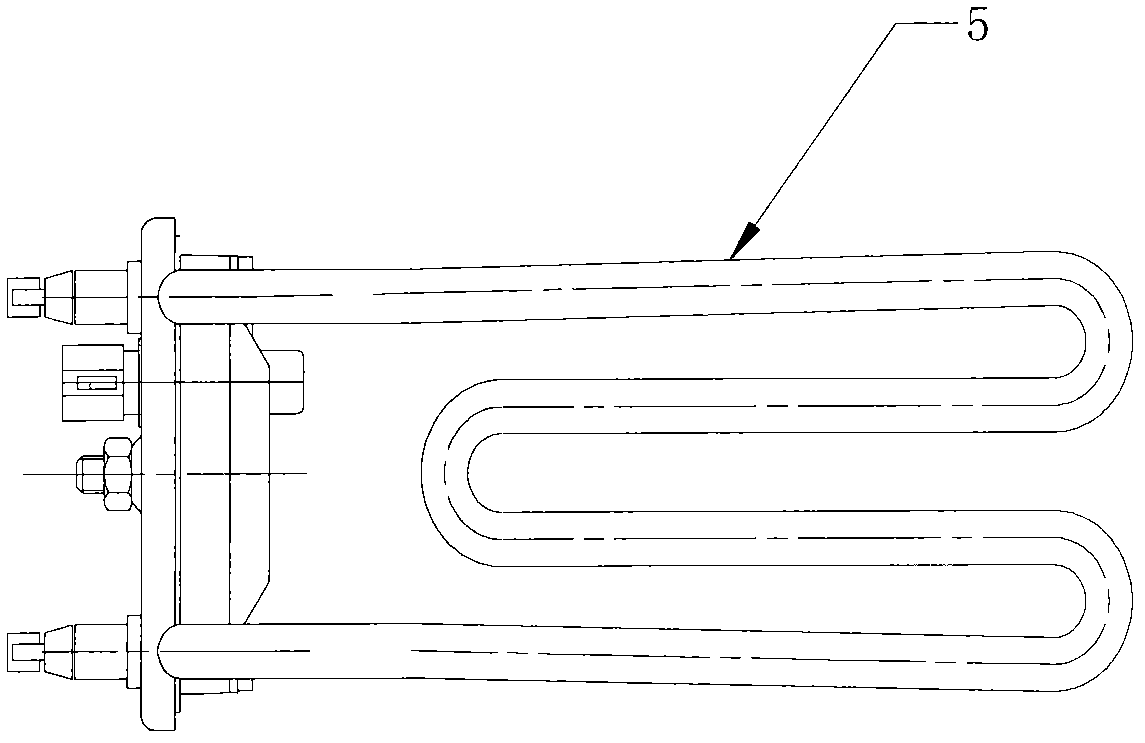

[0045] The heating tube is installed on the outer tub of the washing machine, the battery is 24V20AH, and the power of the heating tube is 1800W. When the user selects the high-temperature heating program to start during the washing process, the main control unit of the washing machine immediately switches the power input to the grid power input through the power switch unit (this process is a forced switch, that is, whether the current power input is battery or grid power). At the same time, the washing machine main control unit turns off the relay K1 (relays K1 and K2 are both off before use), and turns on the relay K2, so that the power of the grid power directly drives the full power output of the heating tube to achieve the purpose of rapid heating. During the heating process, the unit prompts the user with current heating information through the display screen, and the relay K2 is disconnected after the heating program is executed.

Embodiment 2

[0047] The heating tube is installed on the outer tub of the washing machine, the battery is 24V20AH, and the power of the heating tube is 1800W. When the user selects the low-temperature heating program during the washing process, the washing machine main control unit obtains the current battery power capacity value through the power analysis unit, including two results:

[0048] (1) The current remaining battery power is sufficient to support the low temperature heating program, and the washing machine main control unit switches the power input to the battery through the power switch unit (this process is a forced switch, that is, whether the current power input is the battery or the grid power). The main control unit of the washing machine controls the heating tube control circuit to turn off the relay K2 (K1 and K2 are usually off) and turn on the relay K1. At the same time, the control angle a corresponding to this low-temperature heating program controls the thyristor and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com