Sintering segregation distribution controlling method for stabilizing material layer thickness

A technology of material layer thickness and control method, which is applied in the direction of furnace type, furnace, lighting and heating equipment, etc., can solve the problems that the sintering of thick material layer does not take full advantage, and the tracking control of material layer thickness is difficult to achieve stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

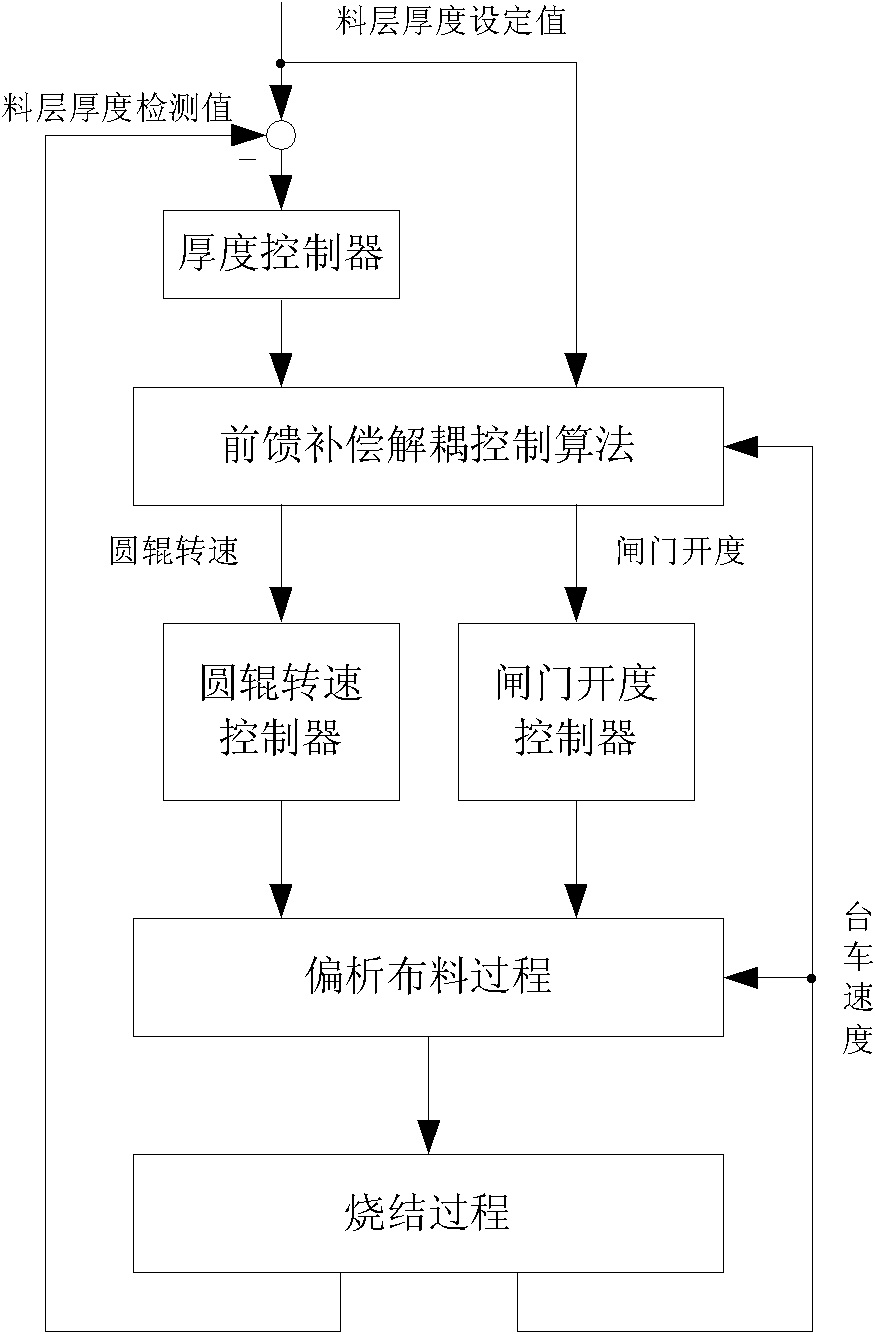

[0026] refer to figure 1 , the method of this embodiment includes the following steps:

[0027] Step 1: Establish a feed-forward compensation decoupling controller to realize the decoupling between the thickness of the material layer, the rotational speed of the round roller feeder and the opening degree of the discharge gate.

[0028] The feed-forward compensation decoupling control algorithm establishes the relationship between the thickness of the material layer, the rotational speed of the round roller and the opening degree of the discharge gate according to the principle of material flow balance.

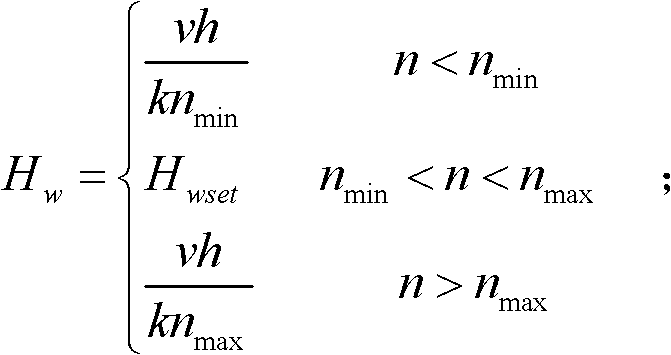

[0029] The feeding amount W of the round roller feeder and the material outflow line speed v w And discharge gate opening height H w And the relationship between the discharge gate width B is:

[0030] W = ρv w BH w =ρnπLBH w (15)

[0031] In the formula, ρ is the bulk density of the material, n is the rotation speed of the roller, and L is the diameter of the rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com