Optical angle measuring device and angle measuring method

An optical measurement and angle technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of high operation and debugging requirements, complex measurement system structure, easy to be affected by environmental factors, etc., to achieve simple structure and measurement accuracy. High and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The angle optical measuring device and angle measuring method of the present invention will be further described in detail below in conjunction with the accompanying drawings.

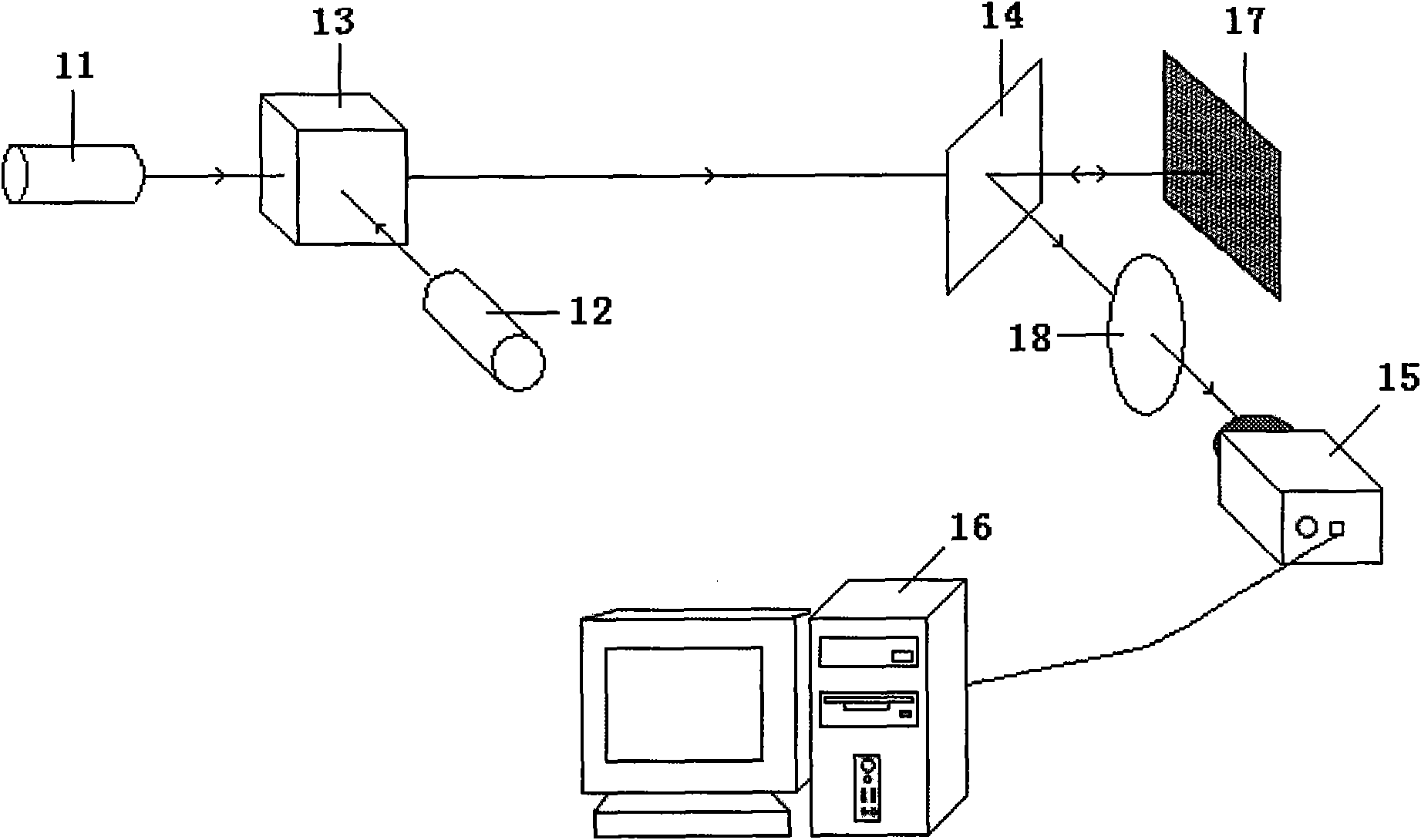

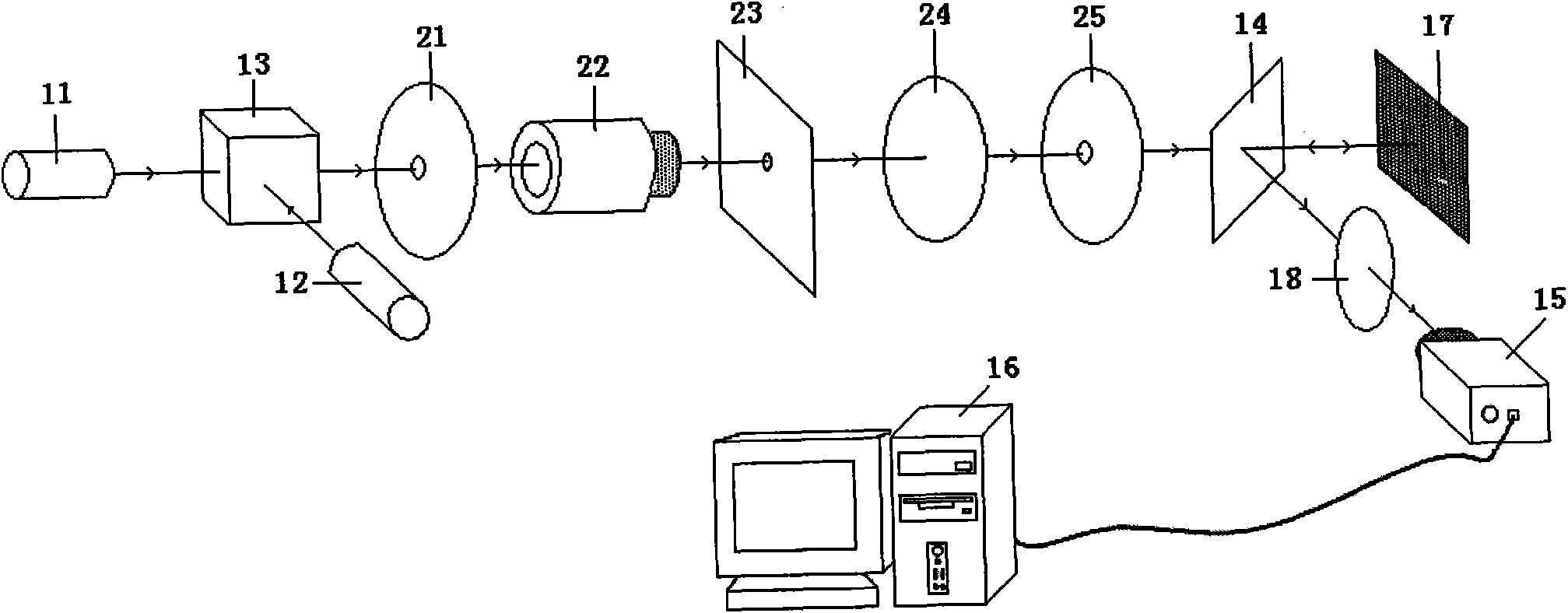

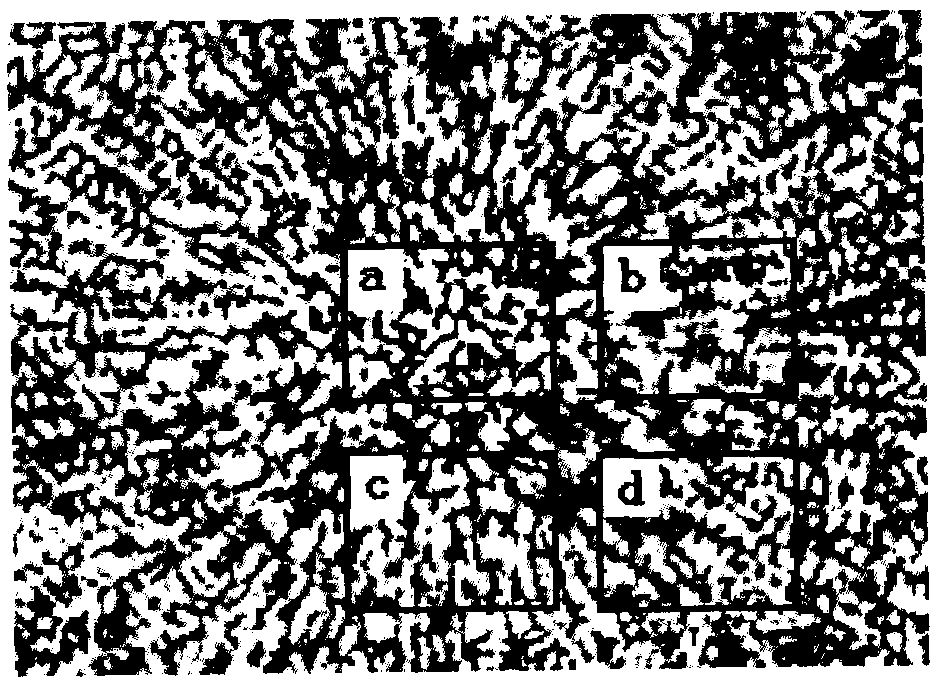

[0030] see figure 1 , the angle optical measuring device comprises two light sources 11 and 12 arranged along the optical axis of the angle optical measuring device, a dichroic prism 13, a half mirror 14, a photodetector 15, an image processor 16, a rough template installed test object ( figure 1 Only the rough template 17) and the first lens 18 installed on the measured object are shown;

[0031] The two light sources 11 and 12 are used to generate coherent light, and the light beams emitted by the two light sources 11 and 12 form a certain angle with each other; The prism 13 combines beams to generate coherent light;

[0032] The dichroic prism 13, the half-mirror 14 and the measured object are arranged in sequence; the coherent light generated by the dichroic prism 13 passes through the ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com