Thin layer liquid membrane measuring and controlling method of metal thin liquid membrane corrosion and electrolytic bath device thereof

A thin-layer liquid film, measurement and control method technology, applied in measurement devices, electromagnetic measurement devices, weather resistance/light resistance/corrosion resistance, etc. and other problems, to achieve the effect of fast measurement and control method and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1, the method of joint measurement and control of open liquid film thickness and occluded liquid film thickness:

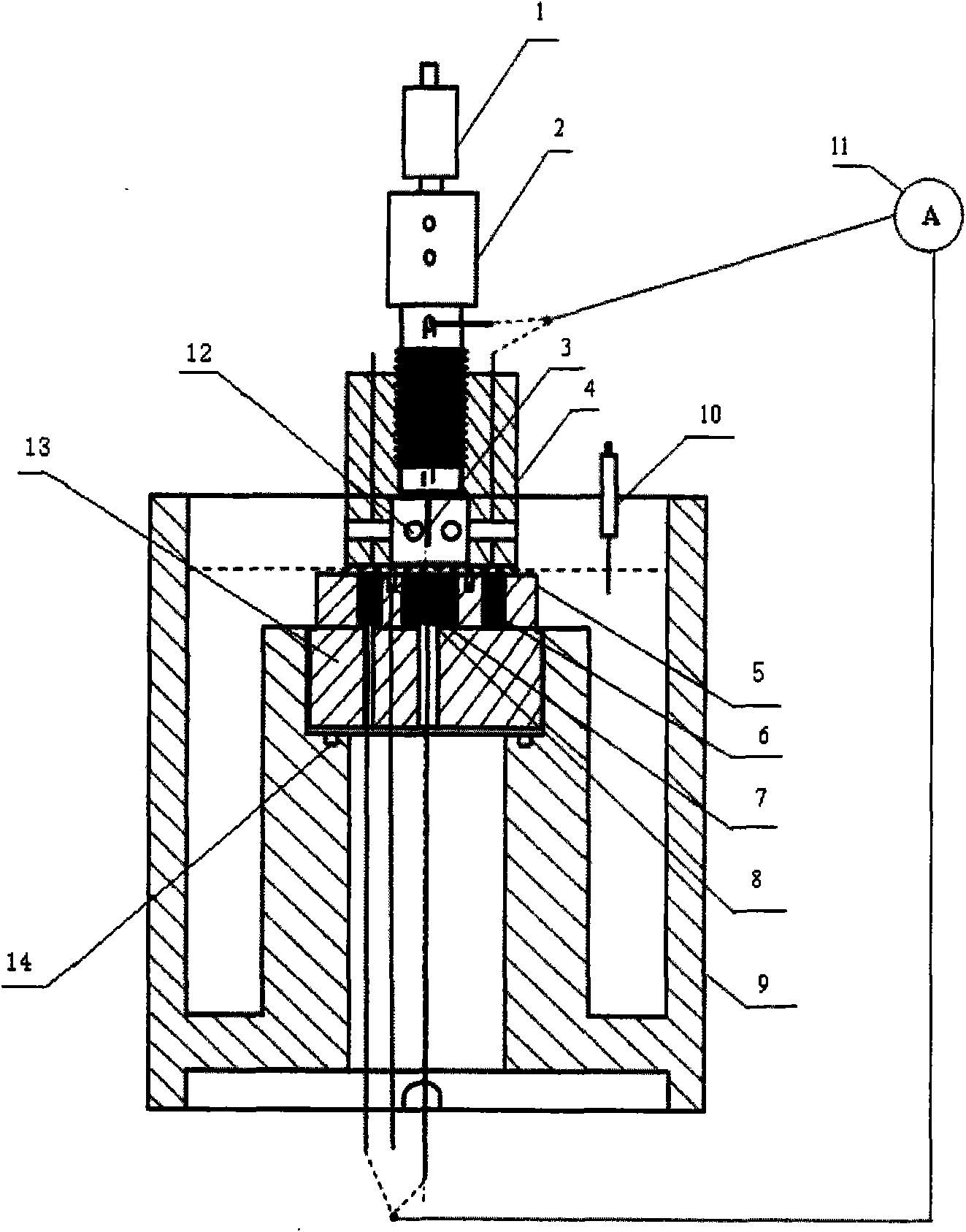

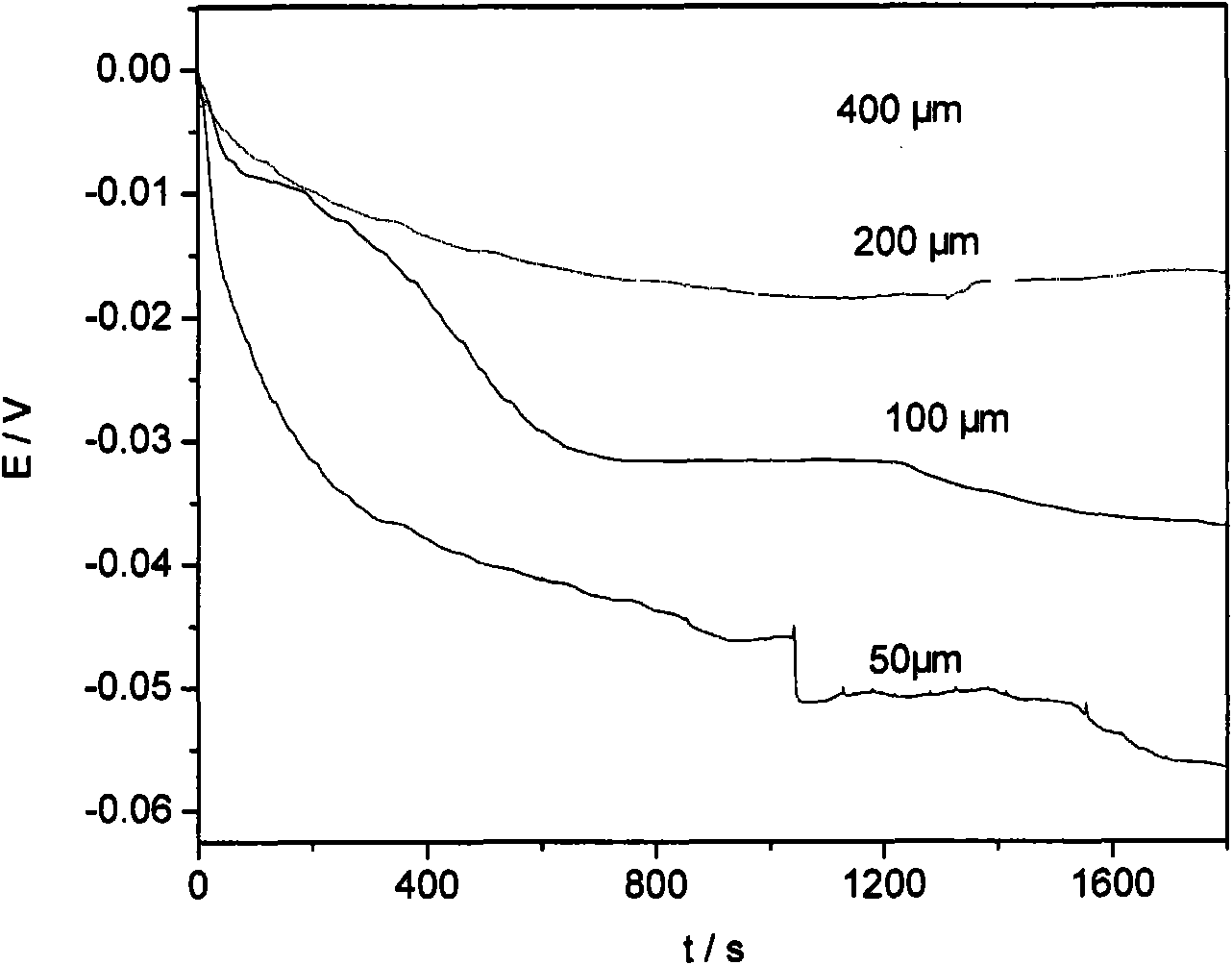

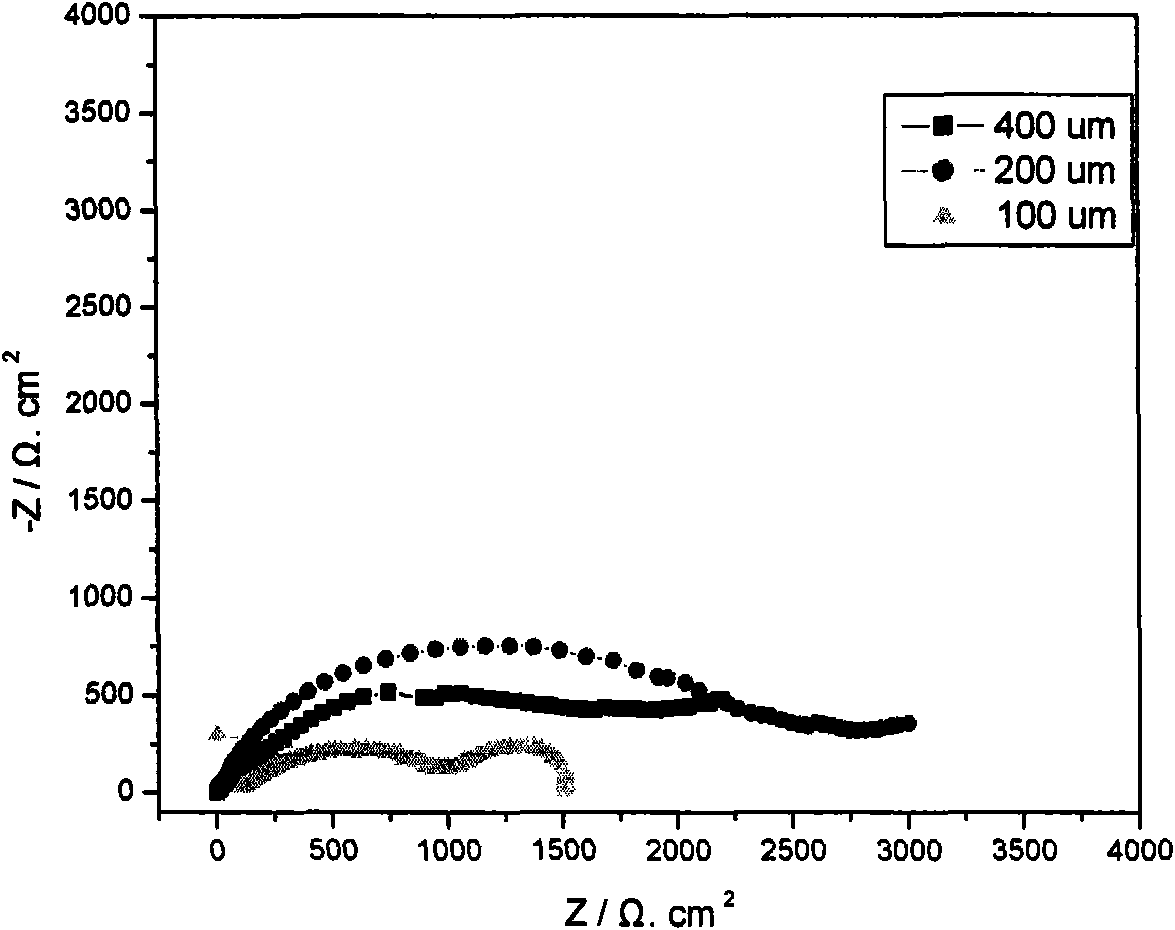

[0017] Round and ring electrodes machined from pure zinc. First, polish the electrode with 600 water-based sandpaper, and adjust the circular and ring electrodes to be at the same level as the electrode table, then rinse the electrodes with distilled water and absolute ethanol, and then dry them with cold air. according to figure 1 After assembling the electrolytic cell device, first connect a zero-resistance ammeter between the circular electrode and the platinum wire at the side end of the externally threaded insulating rod to determine whether there is current passing between the circular electrode and the platinum probe, and slowly rotate the screw micrometer Move the platinum probe to the surface of the circular electrode until the zero-resistance galvanometer shows that there is current passing through, count the reading of the spiral micr...

Embodiment 2

[0019] Embodiment 2, the method for separately measuring and controlling the thickness of the open liquid film:

[0020] Round and ring electrodes machined from pure zinc. First, polish the electrode with 600 water-based sandpaper, and adjust the circular and ring electrodes to be at the same level as the electrode table, then rinse the electrodes with distilled water and absolute ethanol, and then dry them with cold air. according to figure 1 After assembling the electrolytic cell device, connect a zero-resistance ammeter between the circular electrode and the platinum wire at the side end of the externally threaded insulating rod to judge whether there is current passing between the circular electrode and the platinum probe, and slowly rotate the screw micrometer to make The platinum probe moves toward the surface of the circular electrode until the zero-resistance galvanometer shows that there is current passing through, counts the reading of the spiral micrometer, then mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com