Method for manufacturing bipolar transistor

A technology of bipolar transistors and manufacturing methods, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., capable of solving problems such as optimization of bipolar transistors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

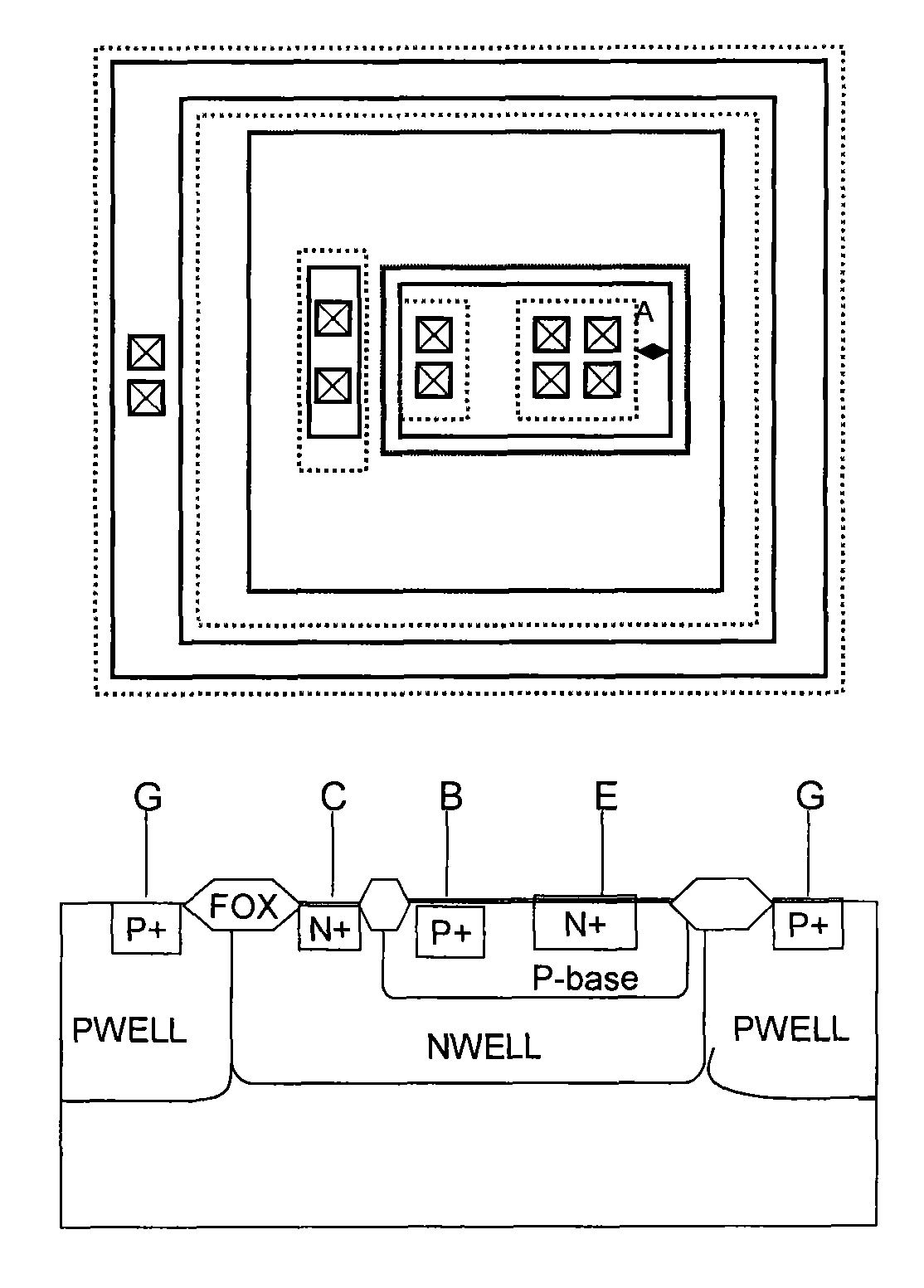

[0026] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

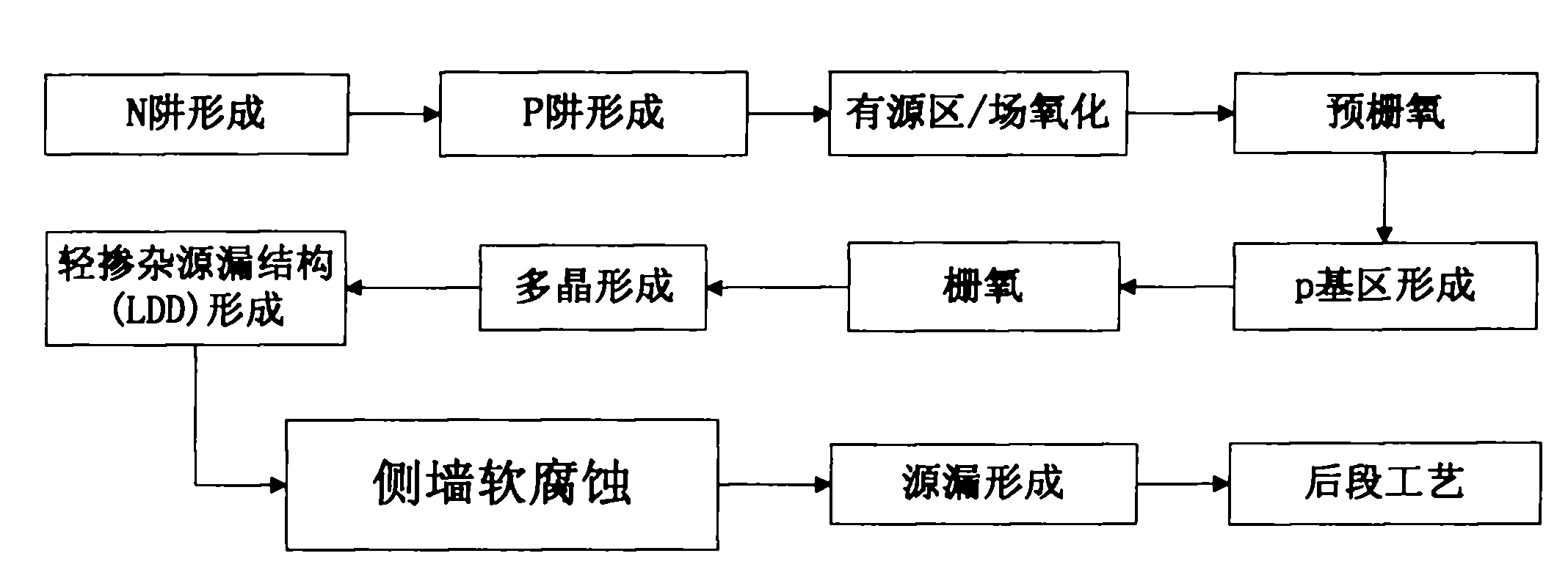

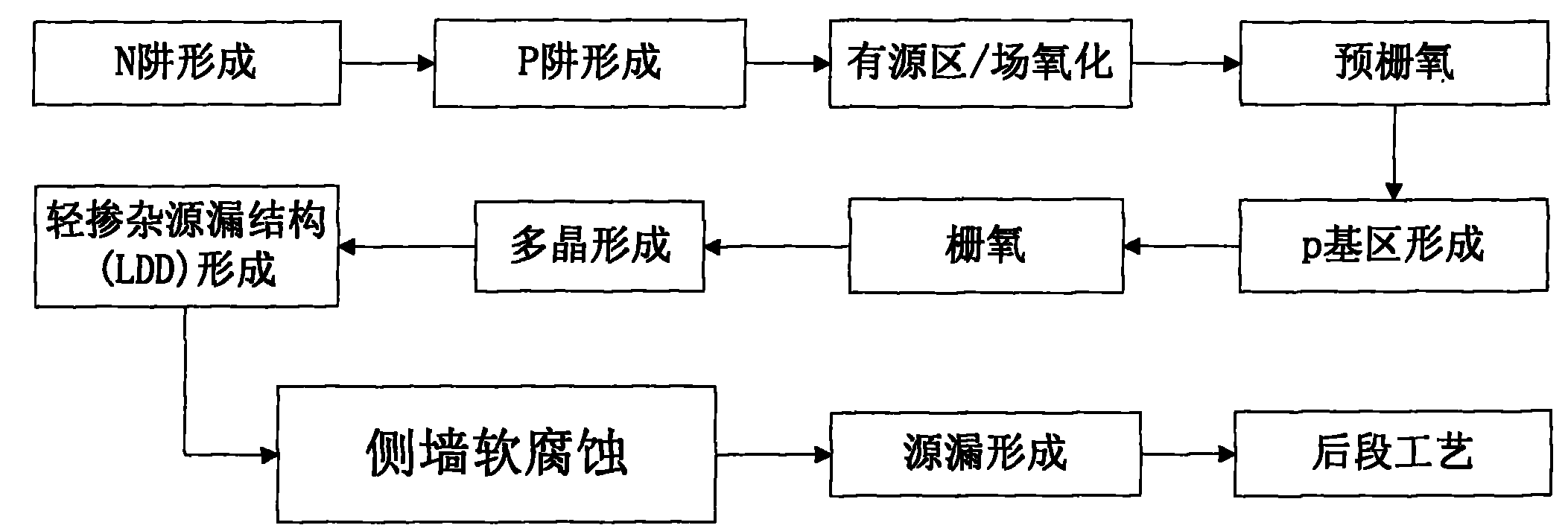

[0027] figure 1 It is a schematic diagram of a manufacturing method of a bipolar transistor according to a preferred embodiment of the present invention. Including the following steps:

[0028] N well formation: the wafer undergoes a photolithography process (photoresist spin coating, photoresist exposure, development, and inspection), and phosphorus ion implantation forms the well region that constitutes the PMOS and the collector that constitutes the bipolar transistor.

[0029] P well formation: The wafer is also formed by photolithography and boron ion implantation to form the well region of NMOS.

[0030] Active area / field oxidation: After the active area photolithography process, after the hard mask is etched away, a field oxide layer is formed by a high temperature and wet oxidation process.

[0031] Pre-gate oxide: After the waf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com