Wire connecting method for line repair

A wiring and circuit technology, applied in the field of semiconductor circuit repair, can solve problems such as accidental short circuit, poor contact, platinum discontinuity, etc., and achieve the effect of improving current function debugging, improving success rate and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

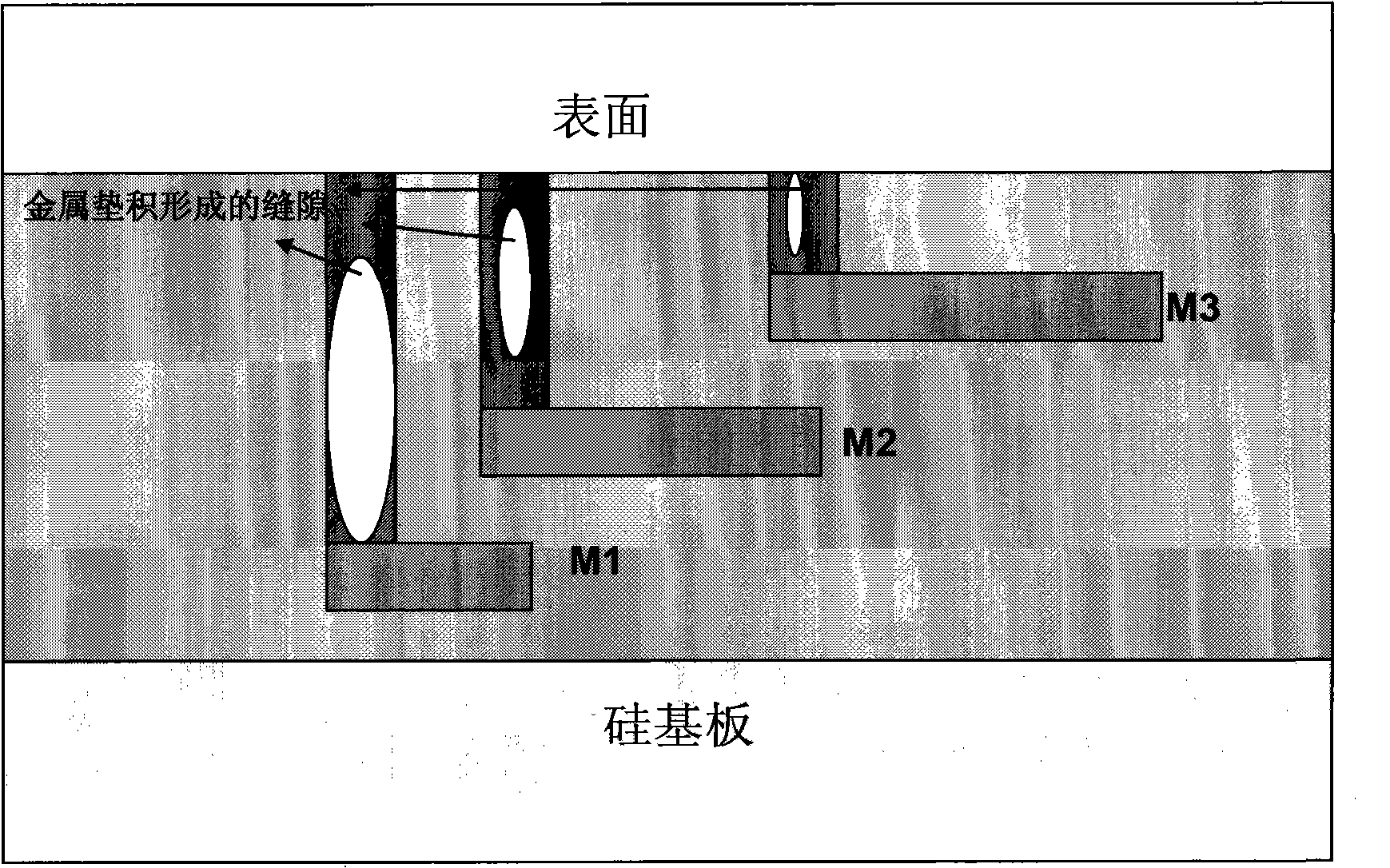

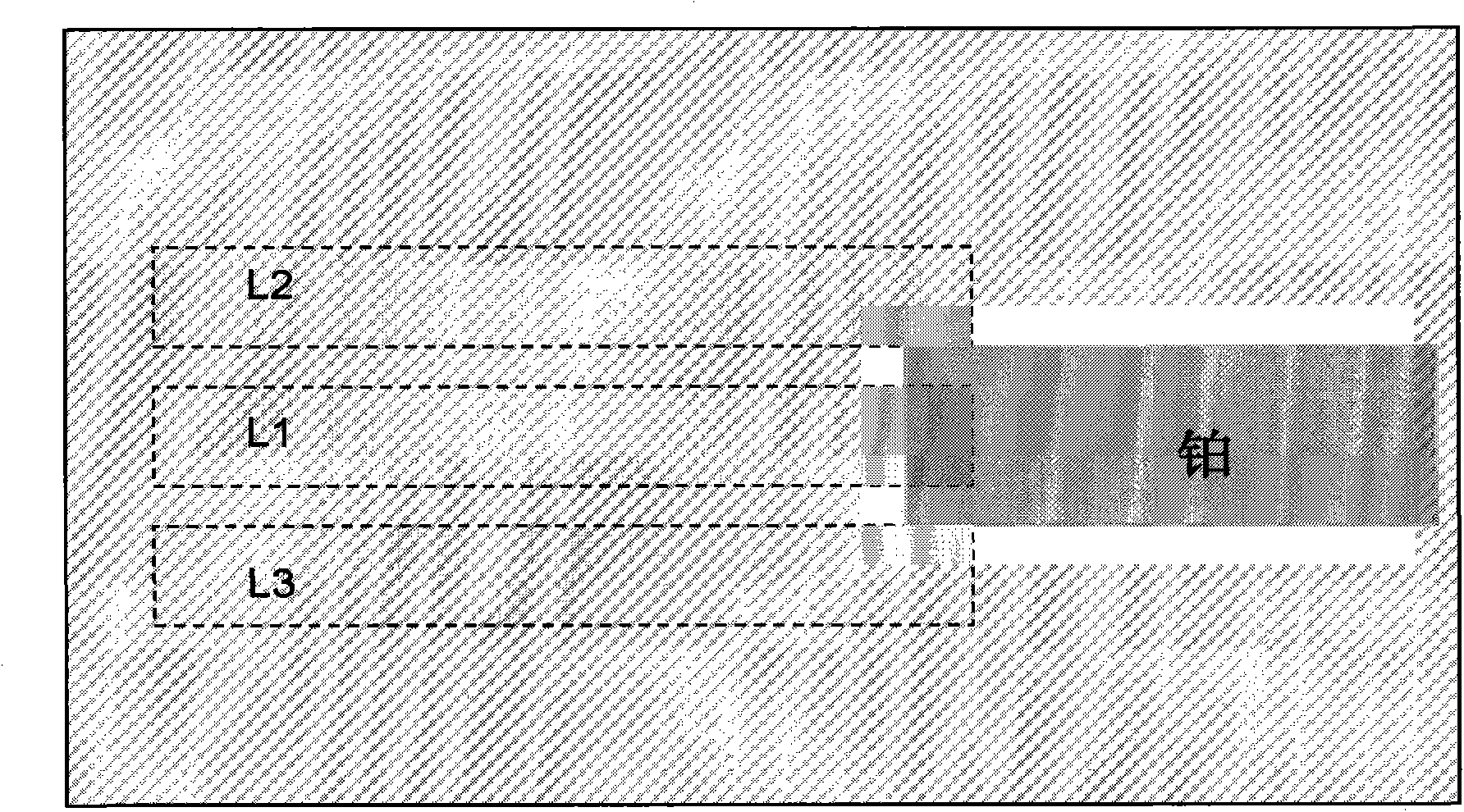

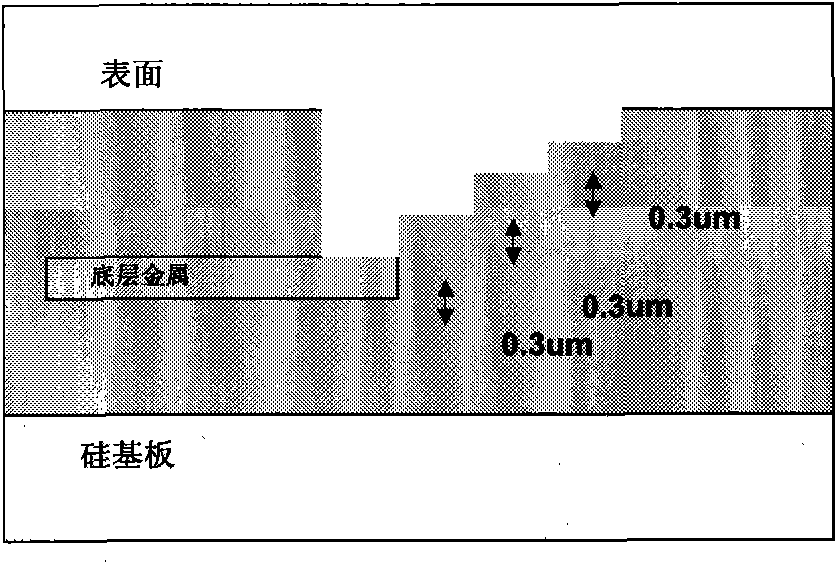

[0028] Focused Ion Beam Electron Microscope FIB (Focused Ion Beam): It uses the focused gallium positive ion beam as the incident particle (or primary ion) to hit the surface of the sample, and collects secondary electrons for imaging. Due to the large atomic weight of gallium ions, it accelerates The rear kinetic energy is large, so it has a good sputtering etching function, and with a suitable gas system, auxiliary functions including selective etching and depositing specific materials can be realized. The gas system it is often equipped with is Pt-Dep (platinum metal deposition system), IEE (selective enhanced etching), I-dep (insulation film deposition), etc.; when working, the gas is sprayed on the surface of the sample, and the ion beam bombards When FIB sets the pattern, it not only directly etches the sample surface, but also impacts some gas atoms on the sample surface; by adjusting appropriate parameters, a layer of platinum metal film can be deposited with Pt-dep, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com