Rapid thermal processing chamber with shower head

A rapid heat treatment and chamber technology, applied in the field of heat treatment, can solve problems such as non-uniform endothermic or exothermic reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

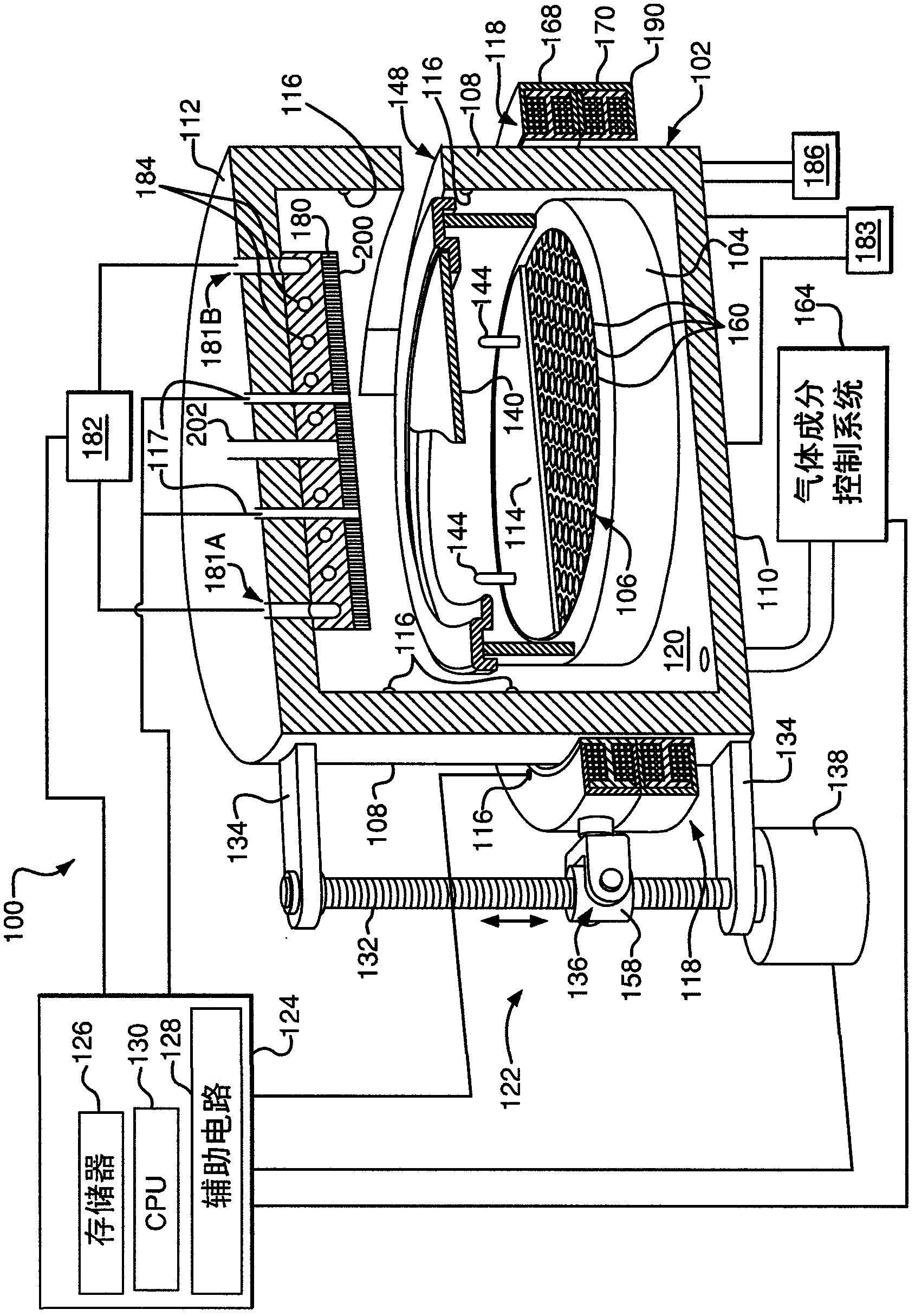

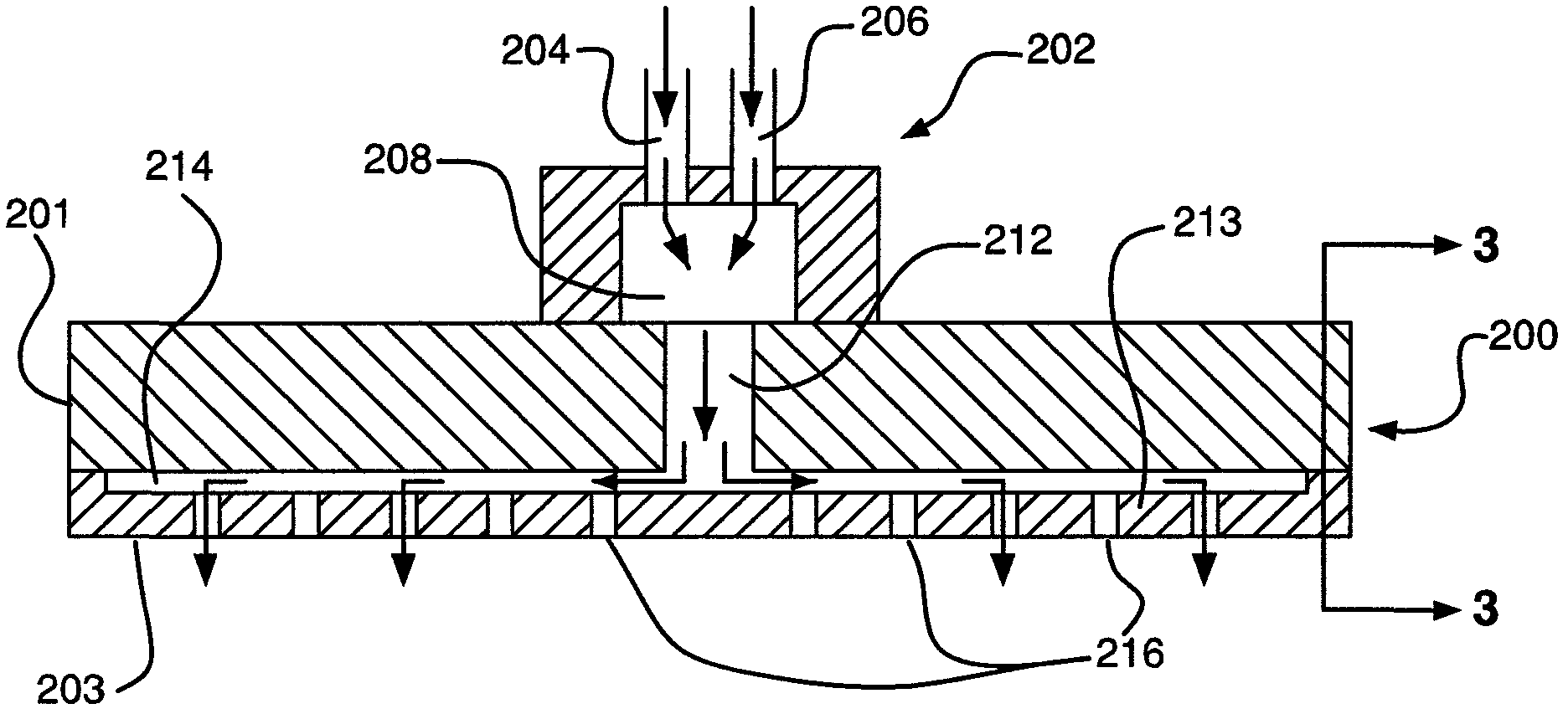

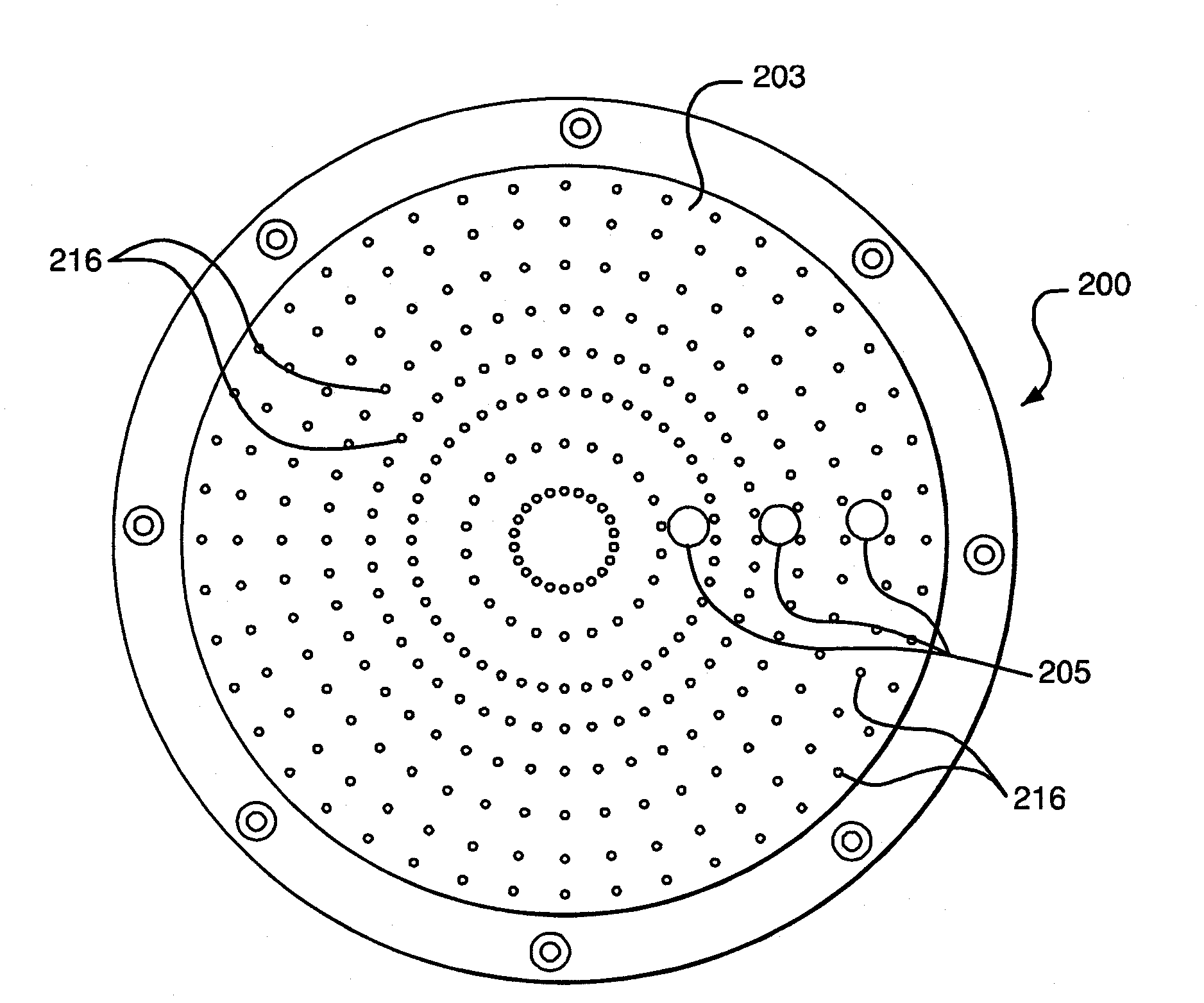

[0019] The embodiments described below generally relate to RTP systems that include a plate incorporating gas distribution outlets to distribute the gas evenly over the substrate, allowing rapid and controlled heating and cooling of the substrate. The panels can be absorptive, reflective, or a combination of both. As used herein, rapid thermal processing or RTP refers to an apparatus or process capable of uniformly heating a wafer at a rate of about 50°C / sec and higher, eg, 100-150°C / sec and 200-400°C / sec. Typical ramp-down (cooling) rates in an RTP chamber are between 80-150°C / sec. Some processes performed in RTP chambers require temperature variations across the substrate of less than a few degrees Celsius. Therefore, the RTP chamber must include a lamp or other suitable heating system and heating control system capable of heating at rates as high as 100-150°C / sec and 200-400°C / sec, unlike rapid thermal processing chambers that do not have the capability to A distinction i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com