Liquid complex enzyme for peeling membranes of orange segments, and compounding process and application thereof

A liquid compound enzyme and decapsulation technology, which is applied in the field of food enzyme preparation application research and development, can solve the problems that affect the competitiveness of canned citrus, pollute the environment with acid-base wastewater, and have no effect, so as to avoid green and technological problems. Barriers, improve product quality, and reduce the effect of broken rate of orange petals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The sources of raw enzyme preparations used in this example are: acid pectinase, xylanase, and β-glucanase are all products of Qingdao Kangdien Biotechnology Co., Ltd.; acid cellulase is from Germany AB Enzyme Preparation Company product.

[0021] Detected according to the enzyme activity detection method selected by the present invention, the activity of each single enzyme used in the present embodiment is: acid pectinase activity: 20211u / ml; acid cellulase activity: 10345u / ml; xylanase activity: 52182u / g; β-glucanase activity: 221232u / g.

[0022] 1. Preparation of liquid compound enzyme:

[0023] Mix 600ml of acid pectinase and 300ml of acid cellulase at a volume ratio of 2:1, stir evenly, and make a mixed enzyme solution of two enzymes, add 100g of xylanase and 100g β-glucanase, stir evenly, and make liquid compound enzyme.

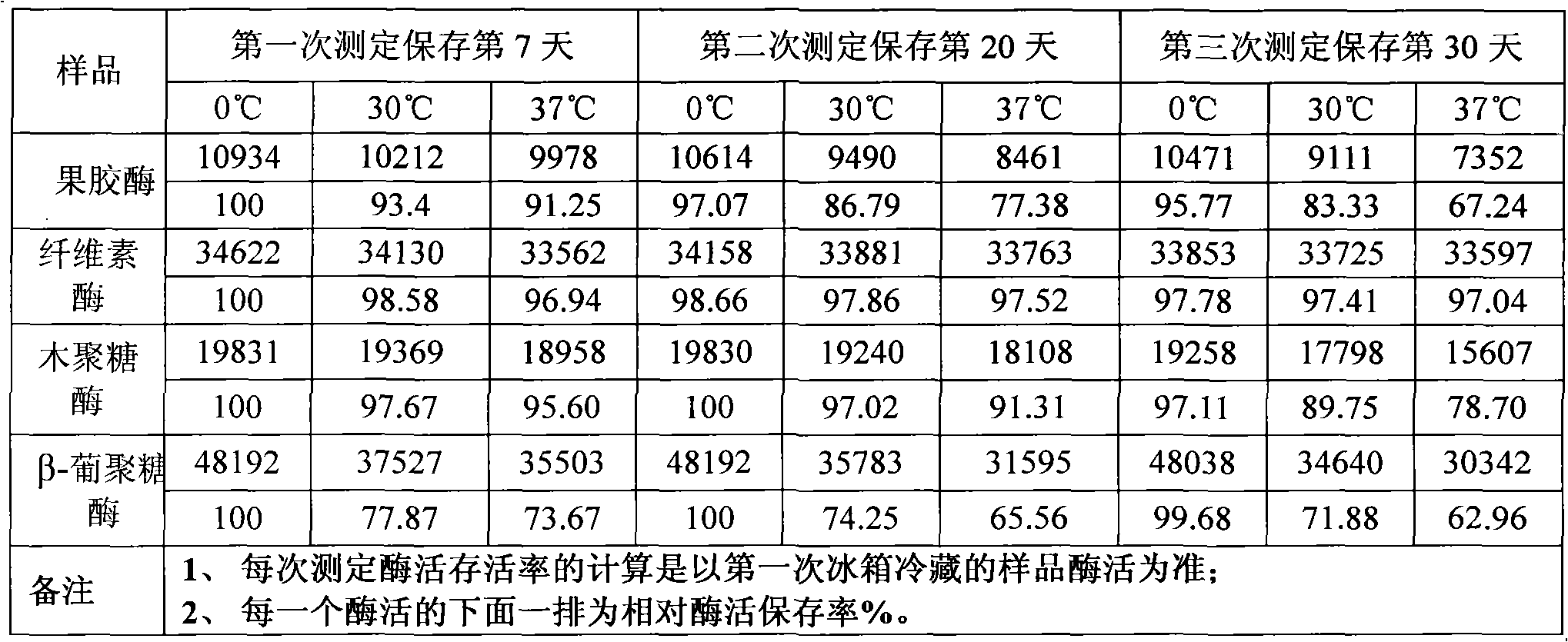

[0024] 2. Stability test of compound enzyme:

[0025] The prepared complex enzymes were stored at 0°C, 30°C, and 37°C respectively, and the...

Embodiment 2

[0033] The sources of raw enzyme preparations used in this example are: acid pectinase, acid cellulase, xylanase, and β-glucanase are all products of Qingdao Kangdien Biotechnology Co., Ltd.

[0034] Detected according to the enzyme activity detection method selected by the present invention, the activity of each single enzyme used in the present embodiment is: acid pectinase activity: 19978u / ml; acid cellulase activity: 9834u / ml; xylanase activity: 30442u / g; β-glucanase activity: 138720u / g.

[0035] 1. Preparation of liquid compound enzyme:

[0036] Mix 640ml of acid pectinase and 160ml of acid cellulase in a volume ratio of 4:1, stir evenly, and make a two-enzyme mixed enzyme liquid, add 200ml of xylanase and 1 / 4 volume of the two-enzyme mixed enzyme liquid respectively 200ml β-glucanase, stir evenly, and make liquid compound enzyme.

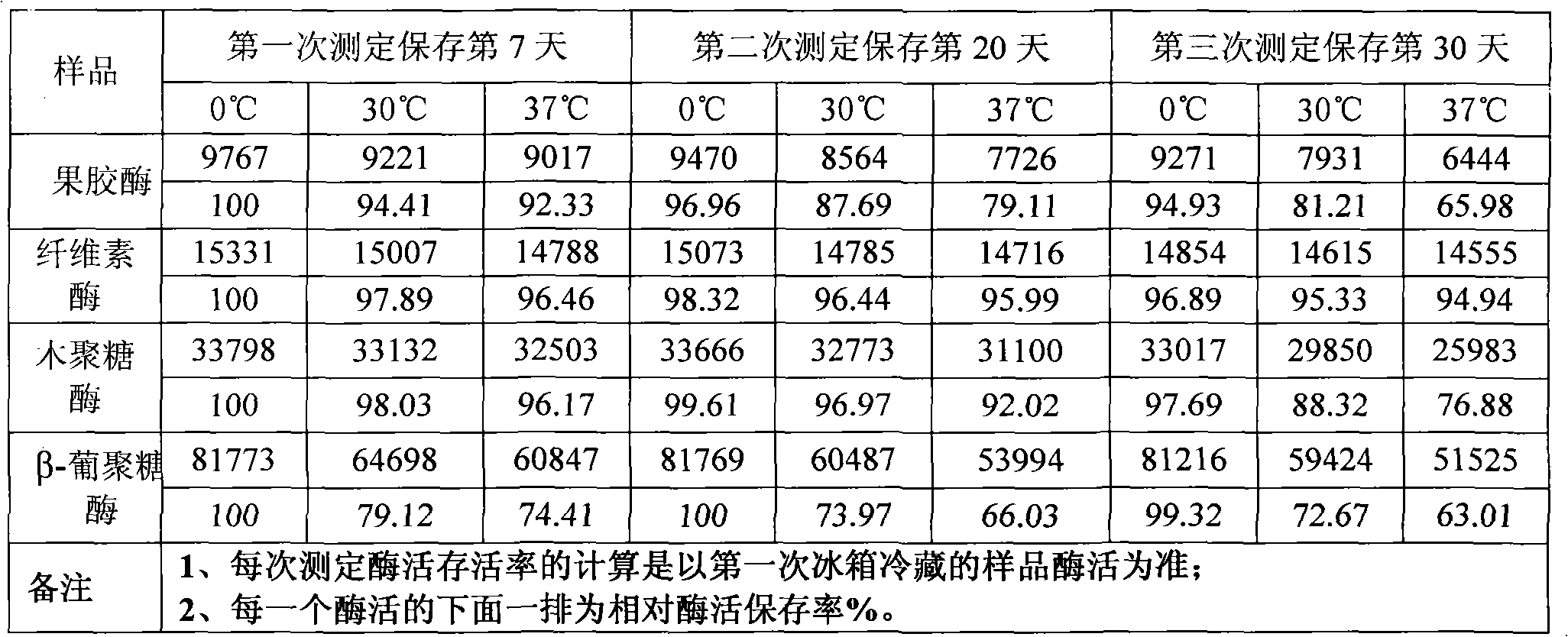

[0037] 2. Stability test of compound enzyme:

[0038] The prepared complex enzymes were stored at 0°C, 30°C, and 37°C respectively, and th...

Embodiment 3

[0046] The sources of raw enzyme preparations used in this example are: acid pectinase is the product of Qingdao Kangdien Biotechnology Co., Ltd.; acid cellulase is the product of AB Enzyme Preparation Company in Germany; xylanase and β-glucanase It is a product of Shanghai Senur Import and Export Trading Co., Ltd.

[0047] Detected according to the enzyme activity detection method selected by the present invention, the activity of each single enzyme used in the present embodiment is: acid pectinase activity: 31233u / ml; acid cellulase activity: 10345u / ml; xylanase activity: 52182u / g; β-glucanase activity: 221232u / g.

[0048] 1. Preparation of liquid compound enzyme:

[0049] Mix 160ml of acid pectinase and 640ml of acid cellulase in a volume ratio of 1:4, stir evenly, and make a mixed enzyme solution of two enzymes, add 160g of xylanase and 160g of β-glucanase, stirred evenly, made into liquid compound enzyme.

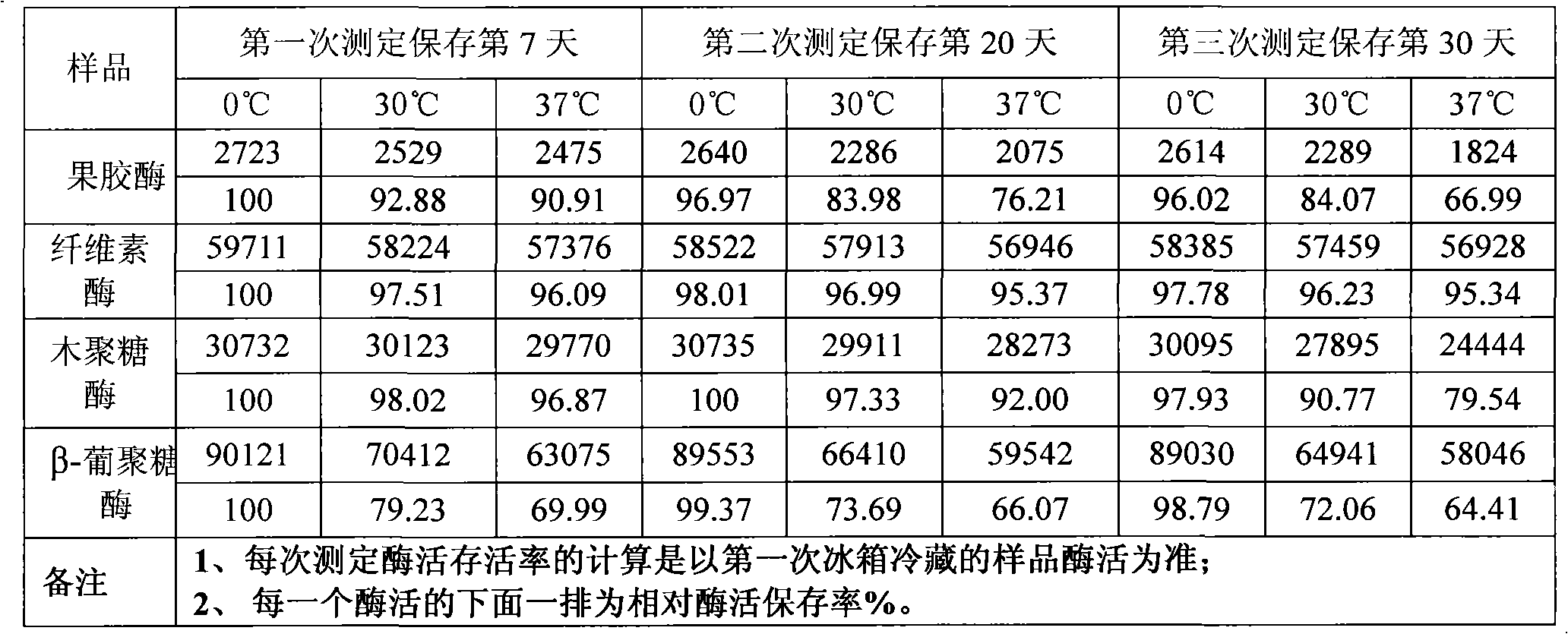

[0050] 2. Stability test of compound enzyme:

[0051] The pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com