Environmentally-friendly tea set and production method thereof

An environment-friendly tea set technology, which is applied to household containers, drinking vessels, etc., can solve the problems of complicated production process, influence on the surrounding environment, large clay consumption, etc., and achieve the effect of saving gem natural resources, avoiding environmental pollution, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with specific examples, which do not represent a limitation to the above-mentioned present invention.

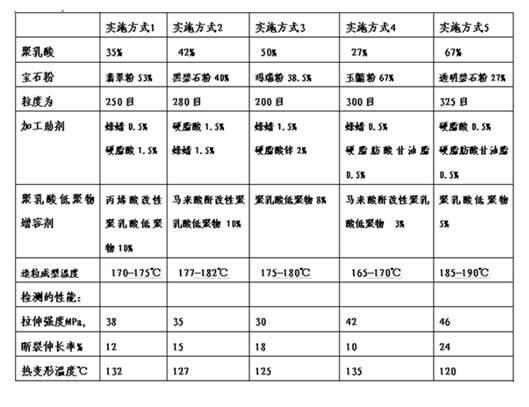

[0021] Table 1 Raw material formula and technical parameters of preparation in various embodiments

[0022]

[0023] Note: The polylactic acid oligomer in the polylactic acid oligomer compatibilizer has a molecular weight of 5,000 to 20,000.

[0024] The preparation method of the environment-friendly tea set comprises the following steps:

[0025] (1) Prepare materials according to Table 1, among which gemstone powder is the powder and leftovers produced by processing gemstone products, which are obtained by removing impurities and crushing;

[0026] (2) The raw materials are mixed evenly by a high-speed mixer, and the mixture is sent to a twin-screw extrusion granulator for mixing, extrusion and granulation into pellets. Mixing extrusion granulation temperature is 165-190°C, speed 250...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com