Photoconductive ink as well as preparation method and use method thereof

A light-guiding ink and photoinitiator technology, applied in ink, application, optics, etc., can solve problems such as light guide plate deformation and ink color shift, achieve the effects of preventing deformation, avoiding color shift, and improving display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

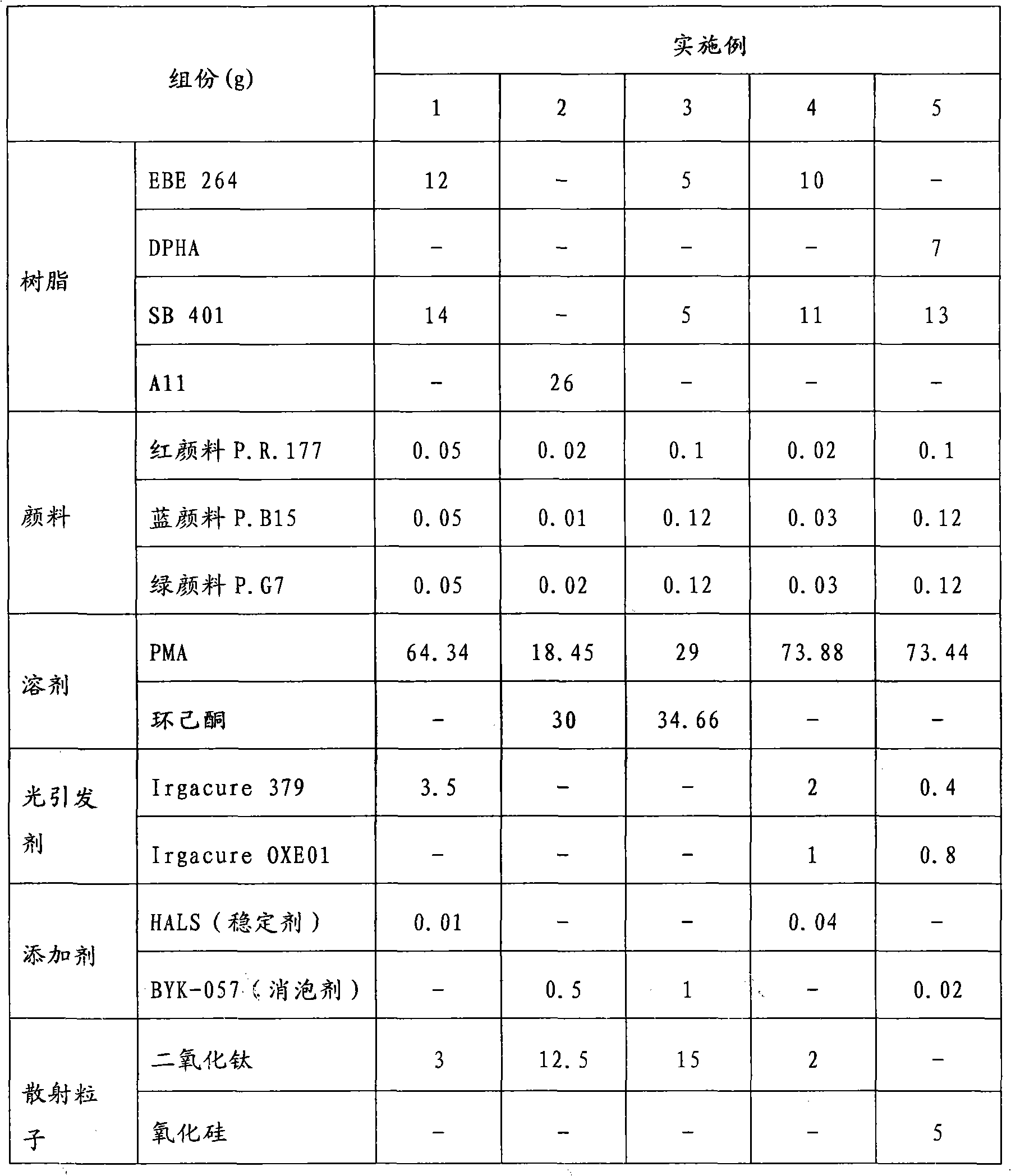

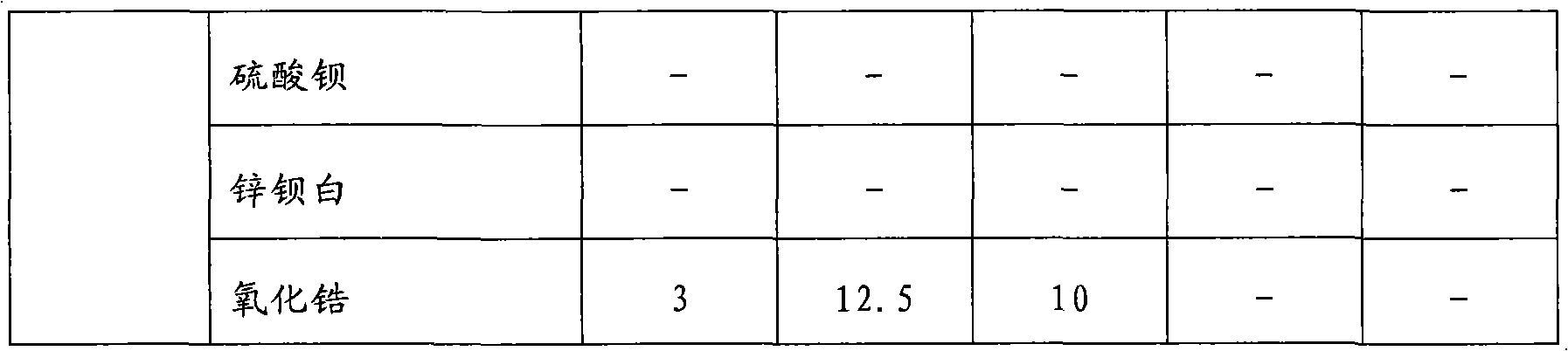

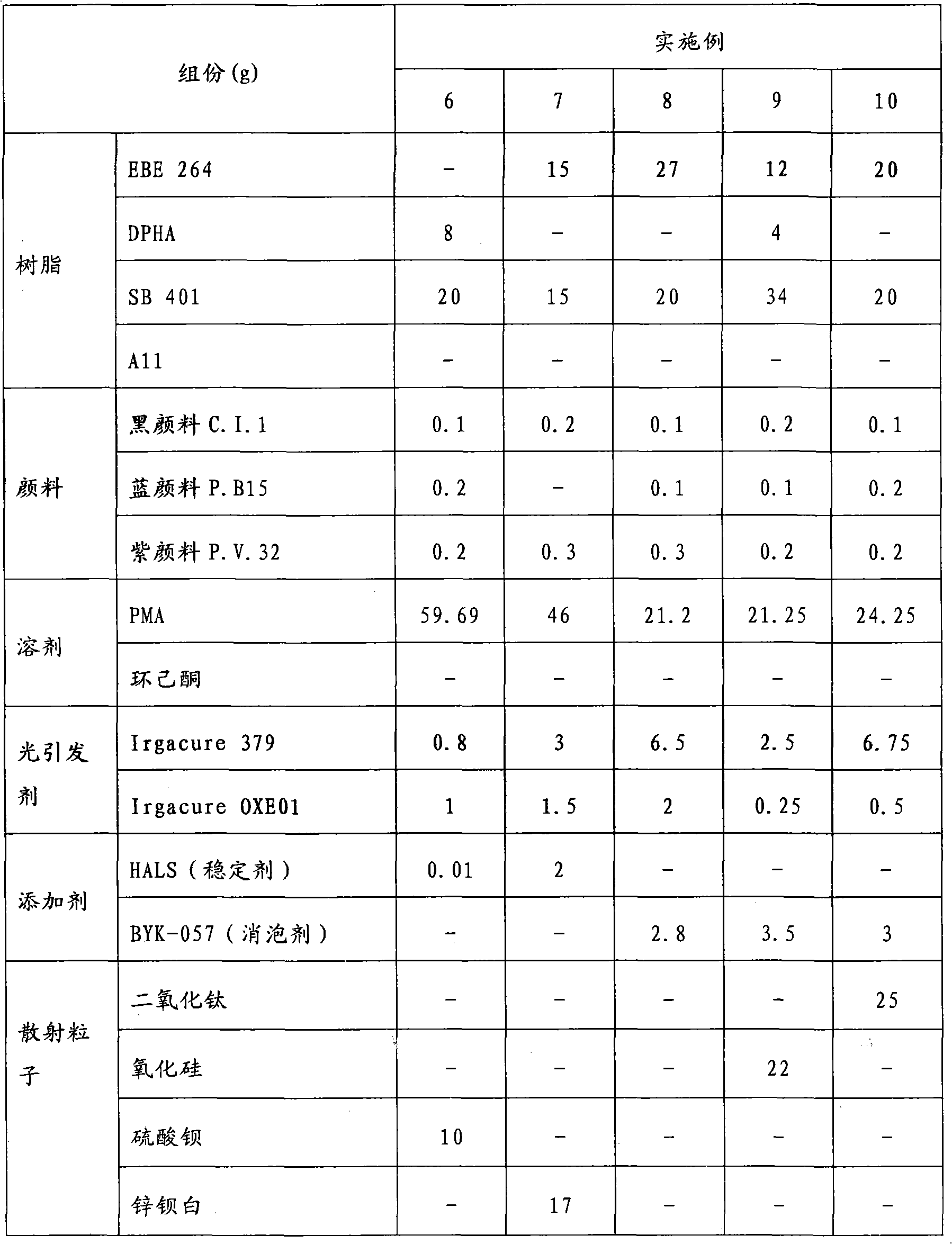

[0029] The light guiding ink of the present invention comprises: 2-25 parts by weight of scattering particles, 10-50 parts by weight of resin, 0.01-0.5 parts by weight of pigment, 20-75 parts by weight of solvent, and 0-8.5 parts by weight of photoinitiator And 0.01-3.5 parts by weight of additives.

[0030] Among them, the characteristics of the material of the scattering particles determine the refractive index of the light-guiding ink. If the refractive index is too low, the light scattering is weak, and the light uniformity effect cannot be achieved; while the refractive index is too high, the scattering is too strong, which is easy to cause light loss. If the particle size is too small, it is difficult to scatter light and reduce the brightness of the light guide plate; if the particle size is too large, it is easy to cause back reflection light loss, which also leads to a decrease in brightness. In the present invention, titanium dioxide, barium sulfate, magnesium oxide,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com