Three-stage thermal field of polysilicon ingot furnace

A polycrystalline silicon ingot furnace, three-stage technology, applied in the direction of polycrystalline material growth, single crystal growth, crystal growth, etc., can solve the problems of shortened battery life, long production cycle, large production energy consumption, etc., and achieve life conversion. The effect of improving efficiency, shortening production cycle and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

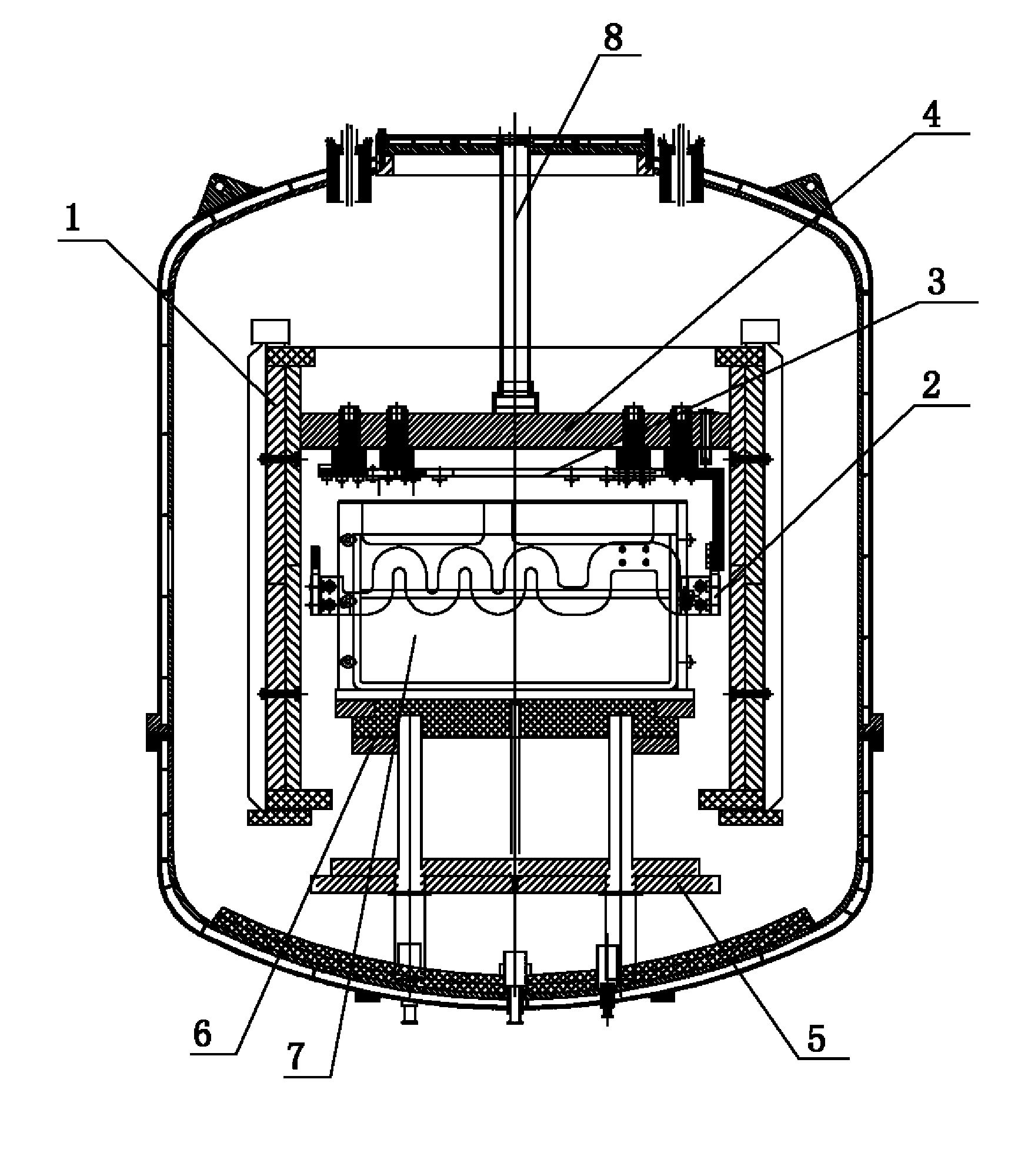

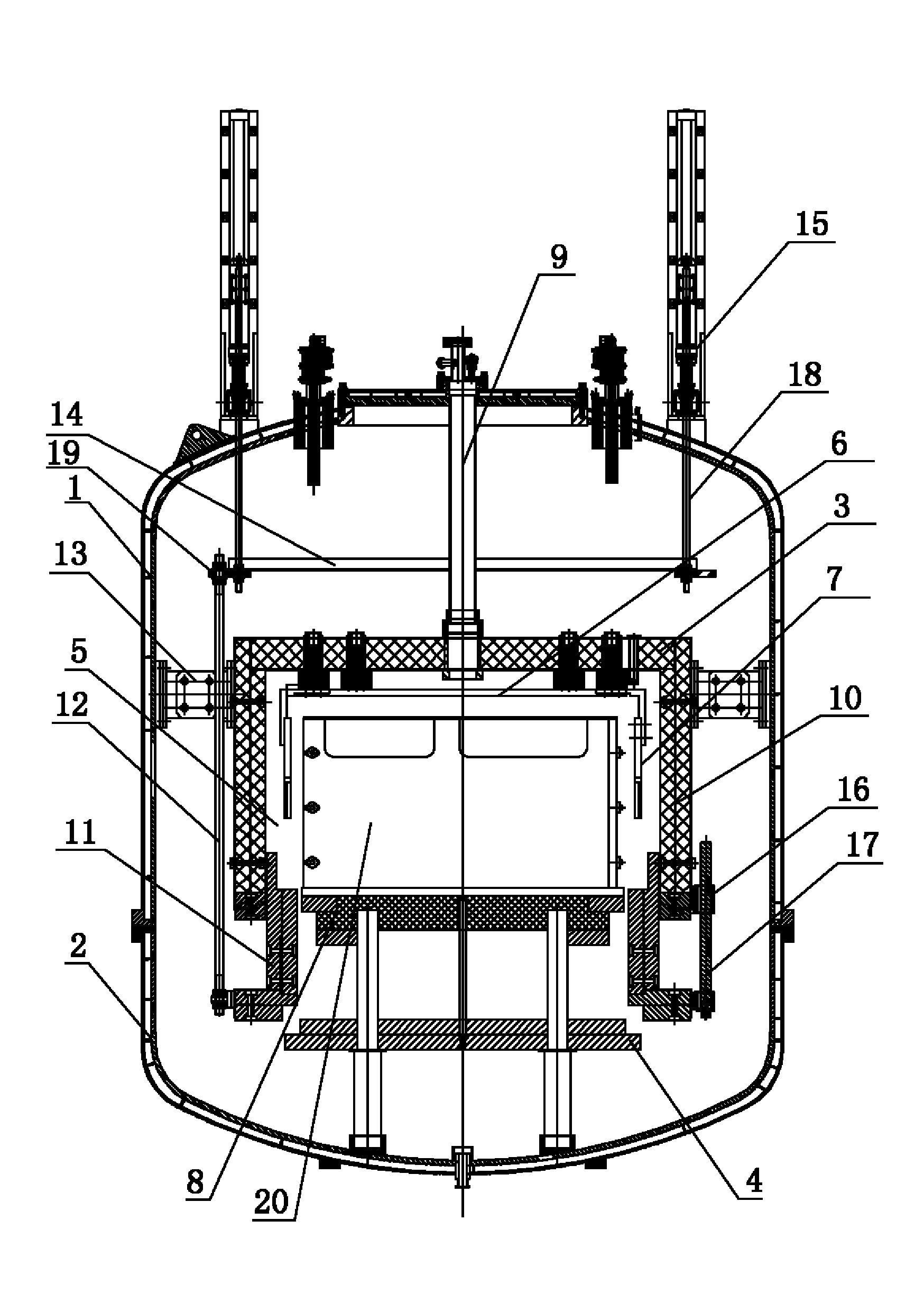

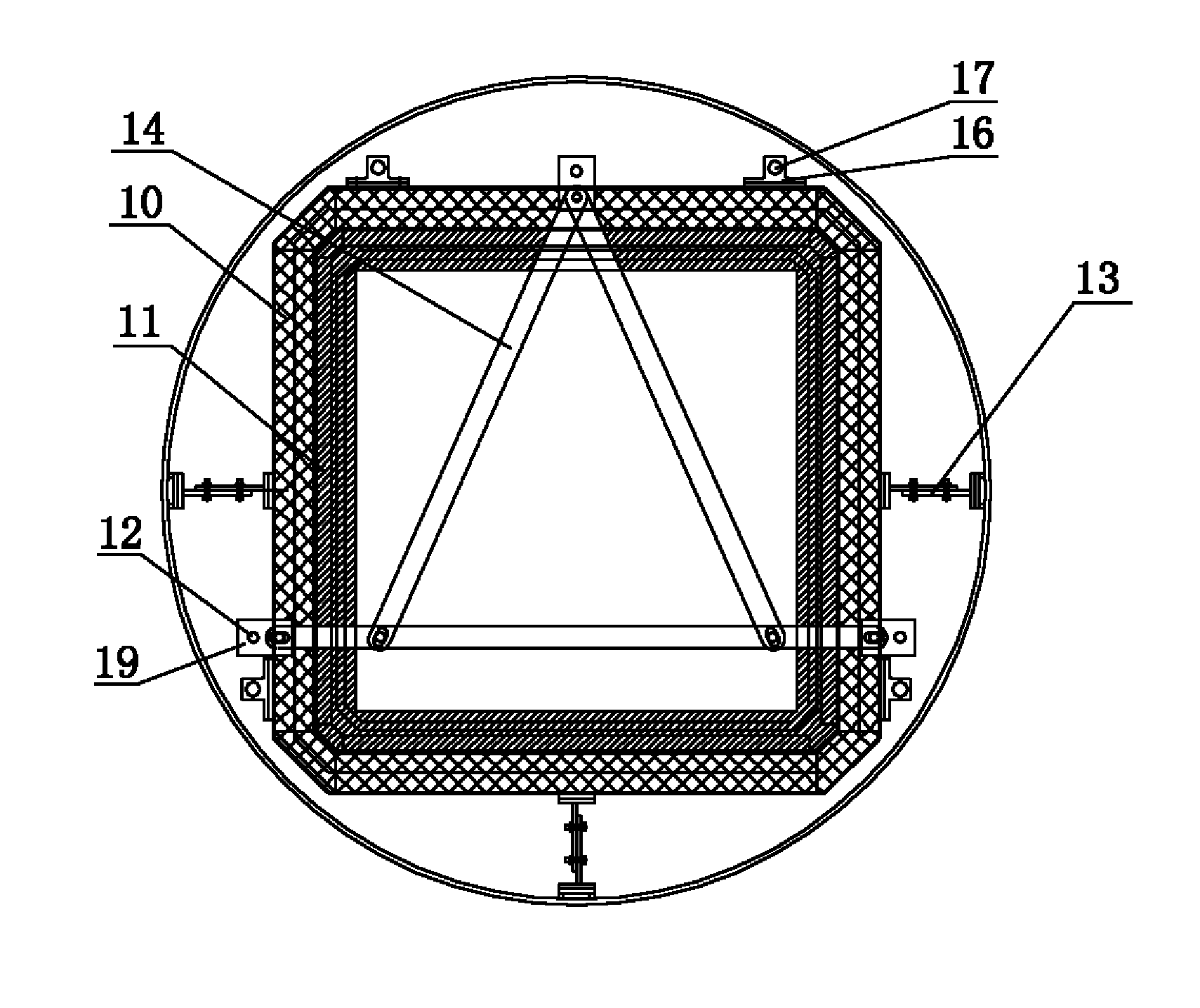

[0014] See figure 2 , image 3 , which includes a furnace chamber, the furnace chamber is composed of an upper furnace shell 1 and a lower furnace shell 2, a top insulation layer 3, a surrounding insulation layer, a bottom insulation board 4, a top insulation layer 3, a surrounding insulation layer, Bottom insulation board 4 forms insulation cavity 5 under the closed state, and insulation cavity 5 is equipped with top heater 6, surrounding heater 7, directional solidification block 8 inside, and top insulation layer 3 is equipped with the intake pipe 9 that goes out downwards, and surrounding insulation layer It includes an upper insulation layer 10 and a lower insulation layer 11, the outer edge surface of the upper insulation layer 10 is fastened to the external fixing seat 13, the external fixing seat 13 is fastened to the inner wall of the upper furnace shell 1, and the outer wall of the lower insulation layer 11 is attached to the upper The inner wall of the thermal ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com