Forced-convection heat transfer experimental device for strong inner heat source containing porous medium passage

A technology of porous media and forced convection, applied in the field of thermal hydraulics, can solve problems such as difficult heating, cold wall effect, and low power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The preferred embodiments of the present invention are given below and described in conjunction with the accompanying drawings.

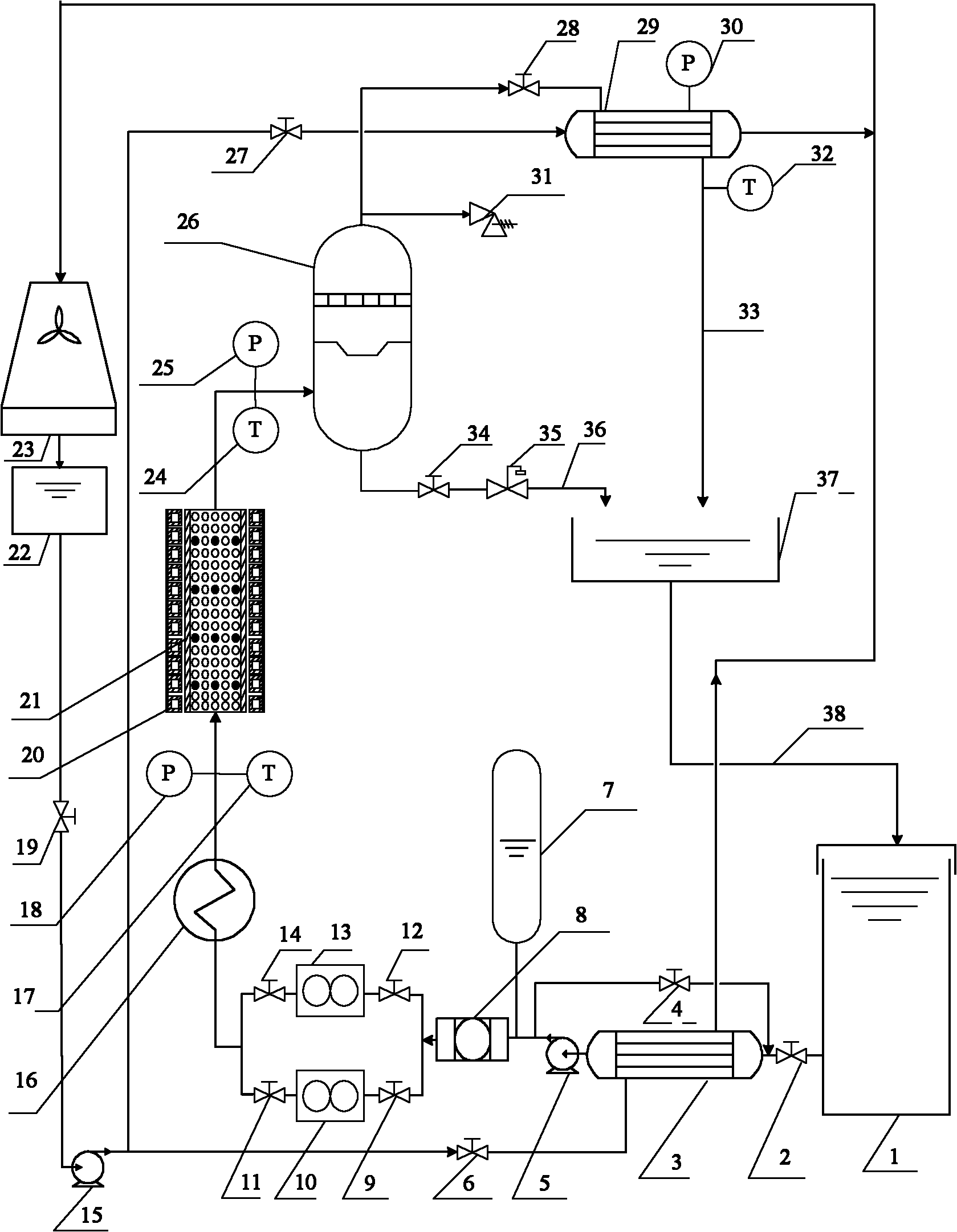

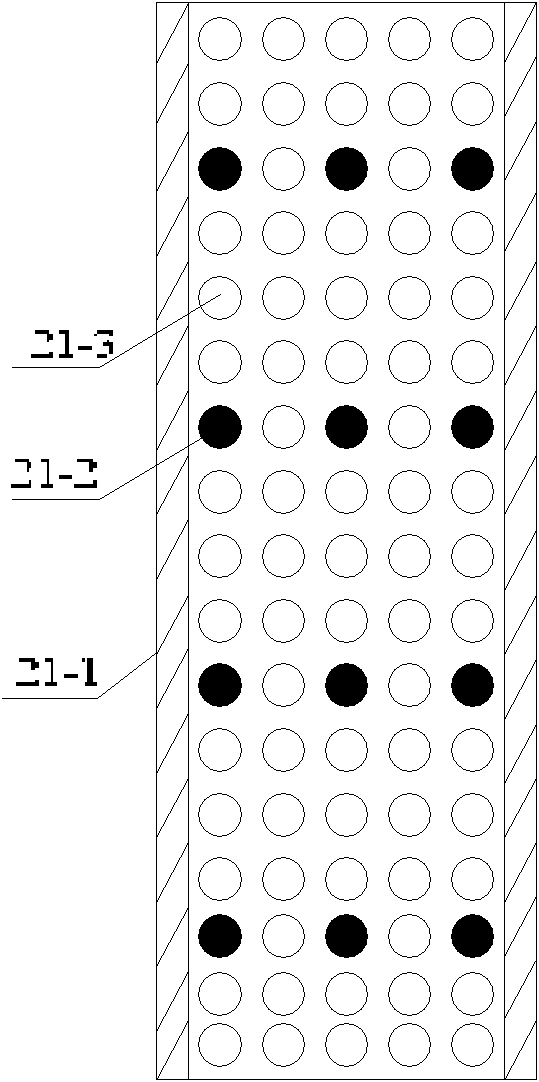

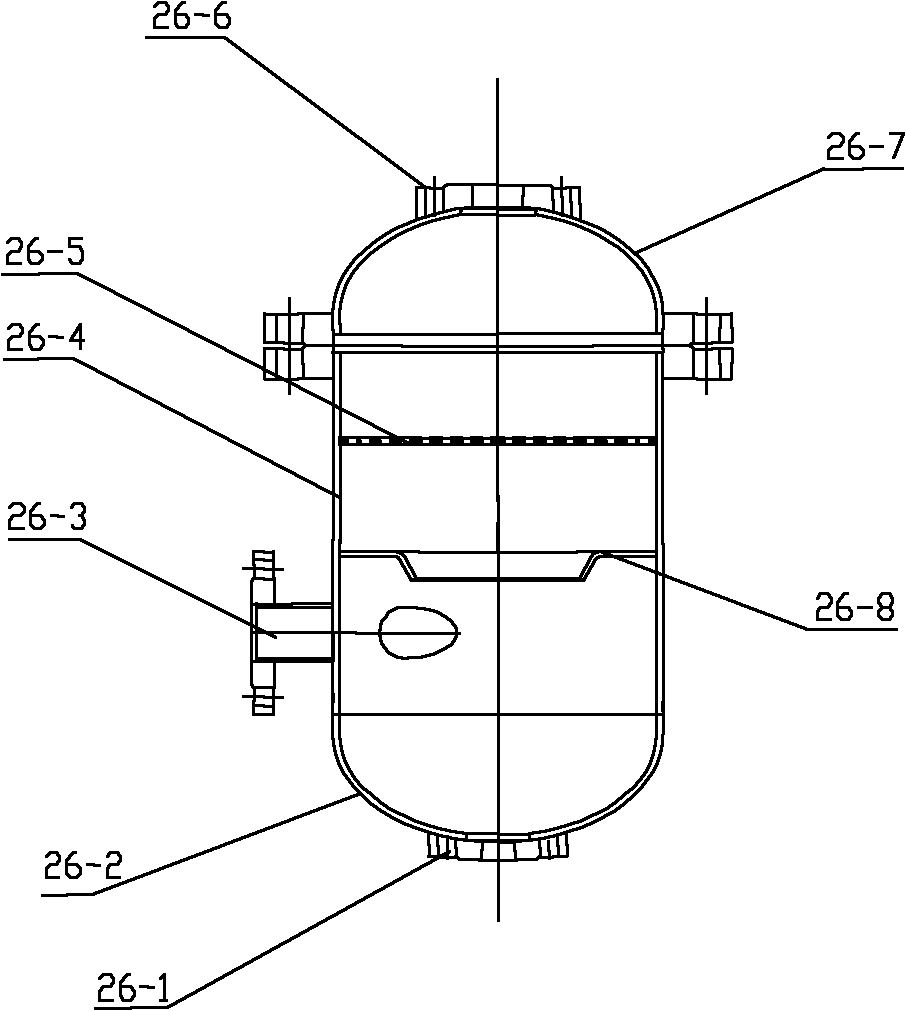

[0034] Such as figure 1 As shown, a porous medium channel forced convection heat transfer experiment device with a strong internal heat source mainly includes a water storage tank 1, a cooler 3, a circulating water pump 5, a surge tank 7, a filter 8, flow meters 10, 13, and a preheater. Heater 16, electromagnetic inductor 20, pebble bed test section 21, steam-water separator 26, condensation-cooler 29, return water tank 37, cooling water pump 15, cooling water tank 22, cooling tower 23, and related valves 2, 4, 6, 9, 11, 12, 14, 19, 27, 28, 31, 34, 35, temperature measuring instruments 17, 24, 32, pressure measuring instruments 18, 25, 30 and data acquisition system.

[0035] The main body of the electromagnetic inductor 20 is a helical coil made of a copper square tube, powered by an intermediate frequency power supply, and by reasonably se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com