Electric operator and wrapping cover thereof

A technology of electric actuators and front packaging, which is applied to the parts, shielding, and instruments of instruments, can solve the problems that the high temperature resistance performance of electric actuators cannot be changed, and the versatility of the covering cover cannot be satisfied, etc., so as to achieve simple structure and low cost. Manufacturing cost and weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

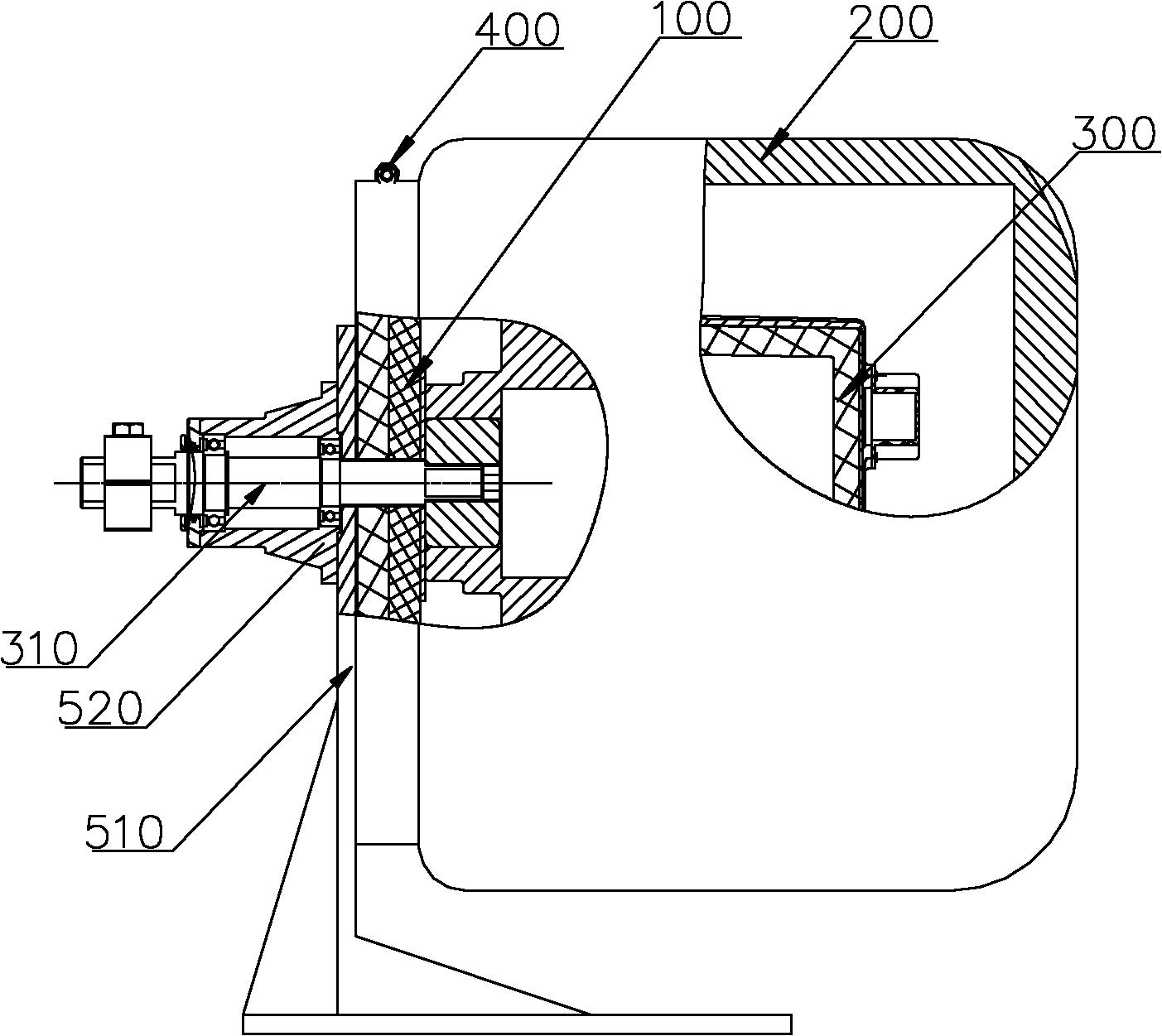

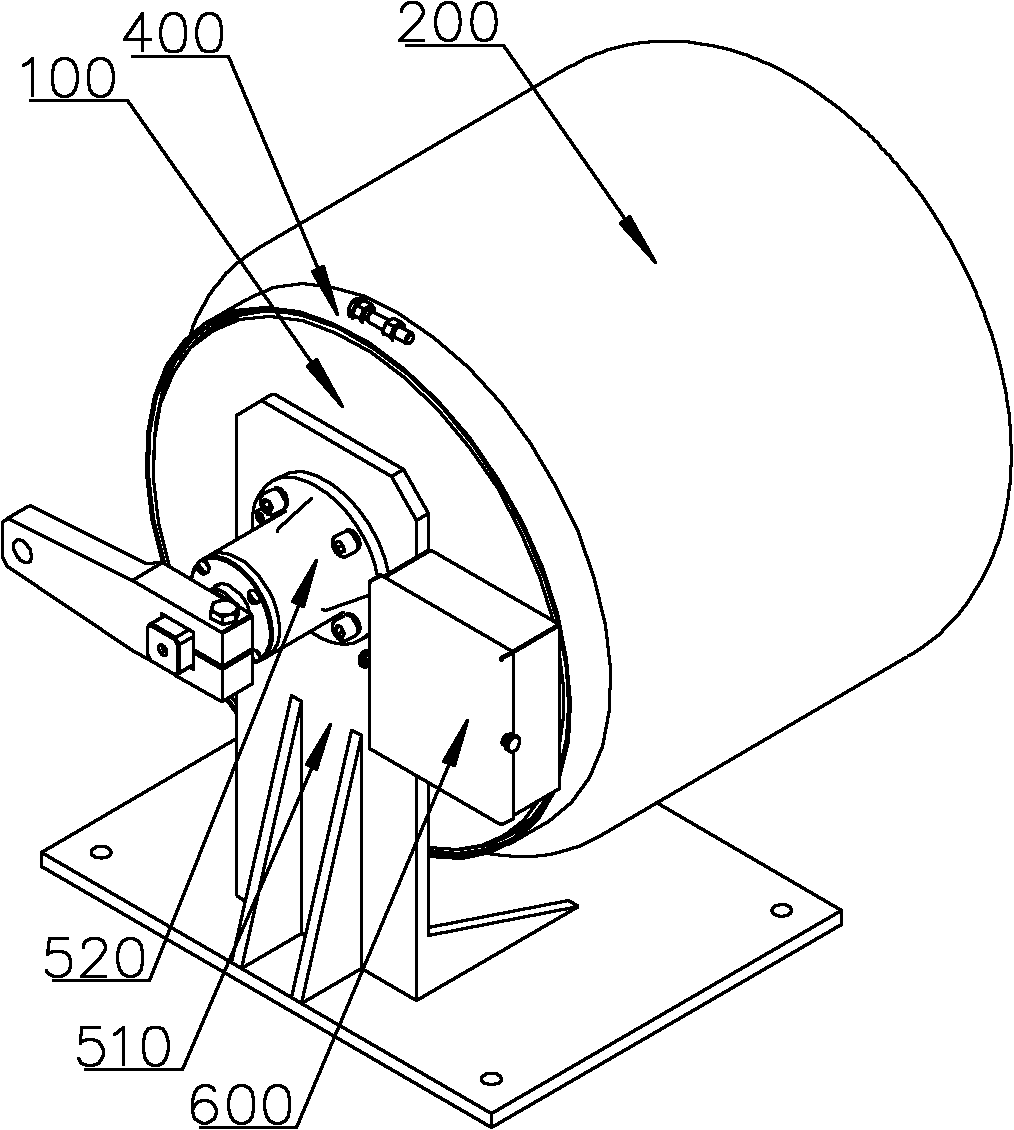

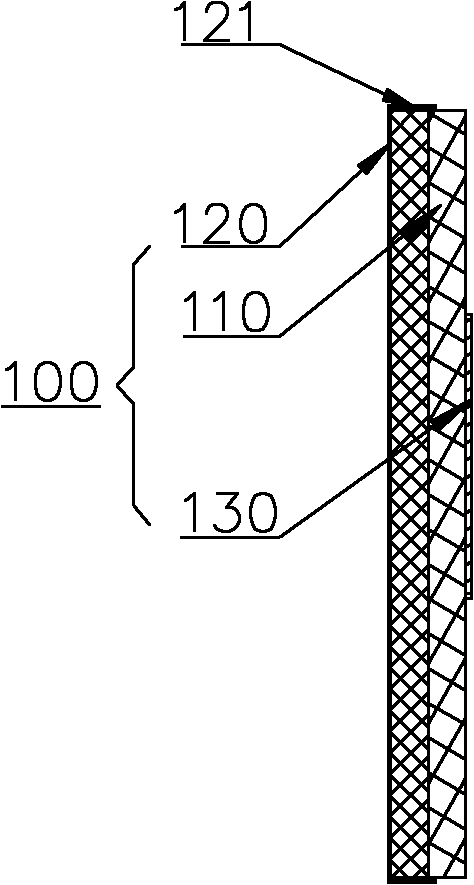

[0038]The present invention will be described in detail below with reference to the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In this section, the front, rear and other directional terms refer to the protruding direction of the power take-off shaft, and the protruding direction of the power take-off shaft is the front, and the opposite direction is the rear.

[0039] For the convenience of description, the electric actuator provided by the present invention and the cover of the electric actuator are described based on the electric actuator in this section, and the cover of the electric actuator will not be described separately.

[0040] Please refer to figure 1 and figure 2 , figure 1 is a cross-sectional structural schematic diagram of the electric actuator provided by the present invention, figure 2 It is a schematic diagram of the three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com