Continuous alkali washing method of C5 petroleum resin

A technology of petroleum resin and alkali, which is applied in the field of deactivation and washing of petroleum resin. It can solve the problems of inability to guarantee the quality stability of petroleum resin, limit the applicability of single-pot operation, and unfavorable continuous operation, so as to reduce the amount of washing, alkali, etc. Good washing effect, sufficient and stable effect of alkali washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

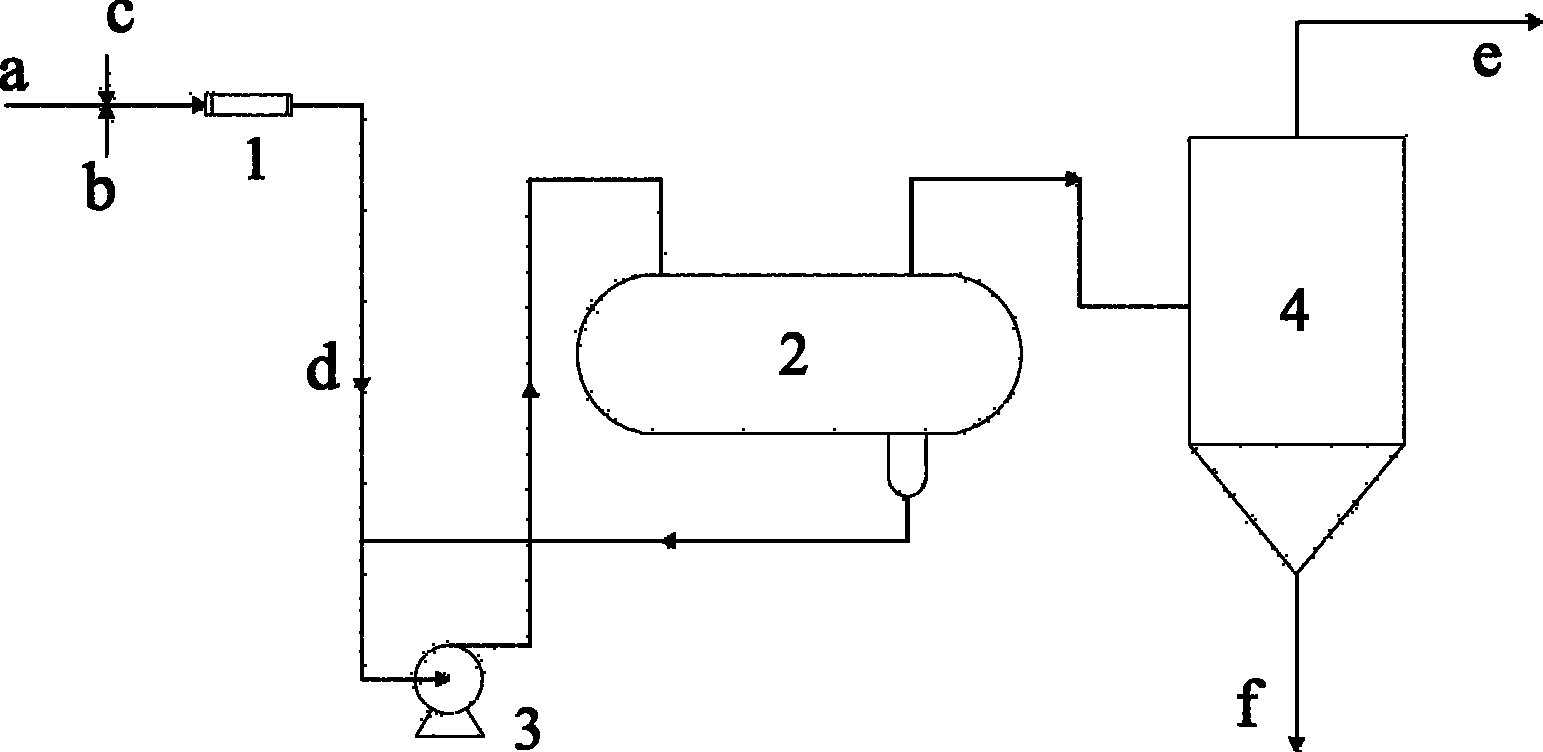

[0024] Petroleum resin polymer solution (a) is mixed with 2% NaOH aqueous solution (b) and 0.2% demulsifier (c) through static mixer (1), enters polymerization termination tank (2) for decatalysis and polymerization termination, using flow 30m 3 / h pipeline pump (3) forcibly mixes the feed liquid in the polymerization termination tank. The mixed material liquid (d) enters the conical settling tank (4) to settle, the resin material liquid (e) enters the next process from the top, and the residue liquid (f) is discharged at the bottom of the settling tank.

Embodiment 2

[0026] Petroleum resin polymer solution (a) and 3% NH 4 OH aqueous solution (b) and 0.3% demulsifier (c) are mixed through a static mixer (1), and enter the polymerization termination tank (2) for decatalysis and polymerization termination, using a flow rate of 40m 3 / h pipeline pump (3) forcibly mixes the feed liquid in the polymerization termination tank. The mixed material liquid (d) enters the conical settling tank (4) to settle, the resin material liquid (e) enters the next process from the top, and the residue liquid (f) is discharged at the bottom of the settling tank.

Embodiment 3

[0028] Petroleum resin polymer solution (a) and 4% Na 2 CO 3 The aqueous solution (b) and 0.4% demulsifier (c) are mixed through a static mixer (1), and enter the polymerization termination tank (2) for decatalysis and polymerization termination, using a flow rate of 50m 3 / h pipeline pump (3) forcibly mixes the feed liquid in the polymerization termination tank. The mixed material liquid (d) enters the conical settling tank (4) to settle, the resin material liquid (e) enters the next process from the top, and the residue liquid (f) is discharged at the bottom of the settling tank.

[0029] The quality indicators of the C5 petroleum resin produced in the above examples 1-3 are: softening point of 105-110° C., hue of 2-3, molecular weight distribution of less than 2.1, and ash content of less than 0.04%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| color hue | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com