Reinforced rubber sheet suitable for construction on steel plate with oil surface at low temperature, and preparation method thereof

A technology for reinforcing film and oil surface, which is applied in the direction of adhesives, epoxy resin glue, film/sheet adhesive, etc., which can solve the problem of insufficient adhesion of oil surface steel plates, poor adhesion of oil surface steel plates, and reinforcement Film construction difficulties and other problems, to achieve the effect of ensuring the bonding effect, saving energy and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment provides a reinforcing film suitable for construction on oily steel plates at low temperatures. The reinforcing film is composed of glass fiber substrates, adhesive layers A and B, and the adhesive layer A is bonded to connected between the glass fiber substrate and the bonding layer B;

[0022] The glass fiber base material of the above-mentioned reinforcing film is used as the skeleton layer of the reinforcing film, and a commercially available thickness of 0.14 to 0.2 mm is an alkali-free glass fiber base material;

[0023] The bonding layer A of the above-mentioned reinforcing film is made up of epoxy resin, epoxy resin curing agent, nitrile rubber, rubber vulcanizing agent, plasticizer and filler, and each raw material consumption of bonding layer A is calculated as: Oxygen resin 20-50%, epoxy resin curing agent 2-5%, nitrile rubber 15-30%, rubber vulcanizing agent 0.5-3%, plasticizer 1-30% and filler 5-40%.

[0024] Among the various raw materials...

Embodiment 2

[0055] This embodiment provides a reinforcing film suitable for construction on oily steel plates at low temperatures, which is suitable for construction on oily steel plates at low temperatures. The preparation method of the reinforcing film is as follows:

[0056] Preparation of adhesive layer A: Add 20 parts of solid nitrile rubber NBR2707 into the open rubber mixer for 2 to 4 minutes to masticate, then add 25 parts of epoxy resin E-51, 20 parts of dioctyl adipate, and 20 parts of heavy calcium 11.5 parts of nano-modified calcium carbonate, 1.5 parts of dicyandiamide, and 1 part of dicumyl peroxide. After mixing for 10 to 15 minutes, thin pass 3 to 5 times, lower the roll, and use a rubber extruder to extrude Form the adhesive layer A film with a width of 300mm, a thickness of 1mm, and a length of 1m for use;

[0057] Preparation of adhesive layer B: Add 17.5 parts of styrene-butadiene rubber SBR1502 to the open rubber mixer for 2 to 4 minutes of mastication, and then add 1...

Embodiment 3

[0060] This embodiment provides the raw materials and preparation method of the adhesive layer A in the reinforced film as in Example 2; the raw material of the adhesive layer B replaces styrene-butadiene rubber SBR1502 with butadiene rubber BR9000, and its preparation method is the same as in Example 2.

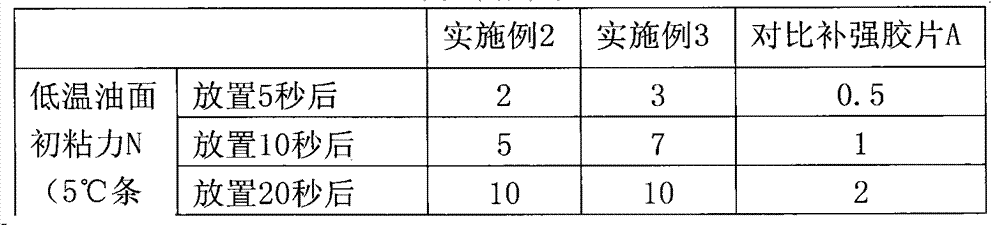

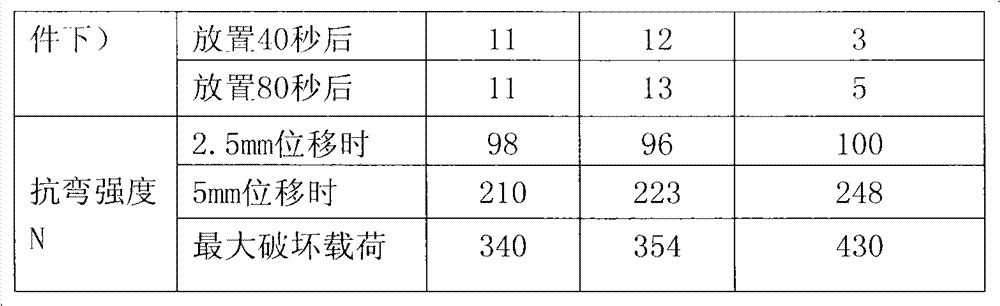

[0061] The reinforcing film made by the above-mentioned embodiment is compared with the currently commonly used reinforcing film, specifically as follows:

[0062] The reinforcing film used for comparison adopts the currently commonly used reinforcing film (hereinafter referred to as the contrasting reinforcing film A), and its adhesive layer is one layer. The main feature of the adhesive layer is that it contains epoxy resin and acrylonitrile group. of nitrile rubber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com