Waste heat recovery system

A technology for waste heat recovery and exhaust gas, which is applied to machines using waste heat, lighting and heating equipment, and combustion methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

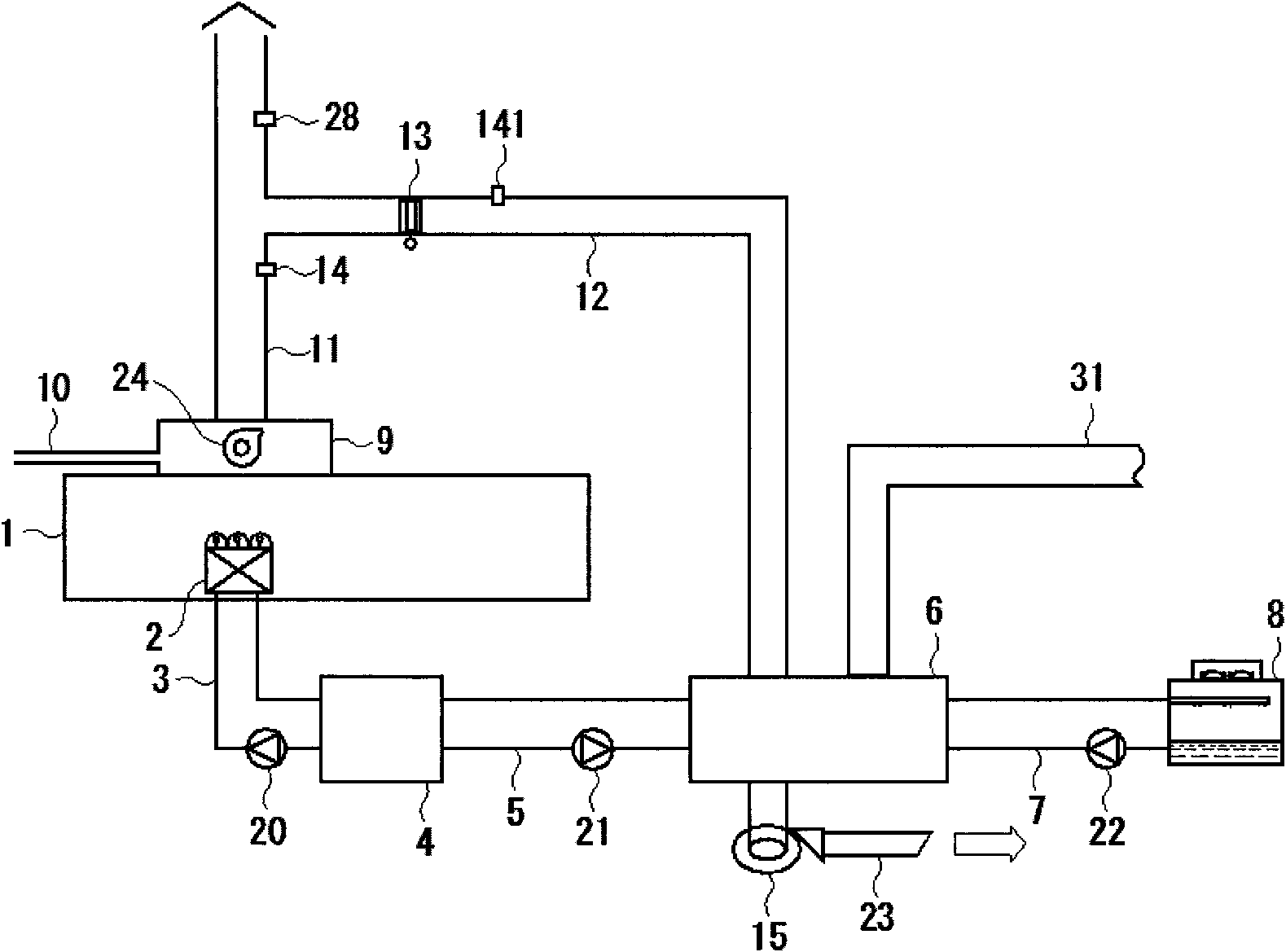

Embodiment 1

[0035] The waste heat recovery system of Embodiment 1 is as figure 1shown. In this specific embodiment, the device that generates VOC is an offset printing machine. The offset printing machine 1 is provided with a cooler 2 for cooling rolls. A cold water buffer tank 4 is connected to the cooler 2 through a circulation pipe 3 . The cold water buffer tank 4 is connected with an exhaust gas absorption refrigerator 6 through a circulation pipe 5 . The waste gas absorption refrigerator 6 is connected to a cooling tower 8 through a circulation pipe 7 . In addition, 20, 21, 22 in the figure are circulation pumps.

[0036] The offset printing machine 1 is provided with a drying function to dry the ink of the printed matter. The offset printing machine 1 is provided with a combustion-type deodorizing device 9 as a VOC treatment device for deodorizing VOC gas containing odor generated by drying ink through the drying function. The fuel is introduced into the deodorizing device 9 t...

Embodiment 2

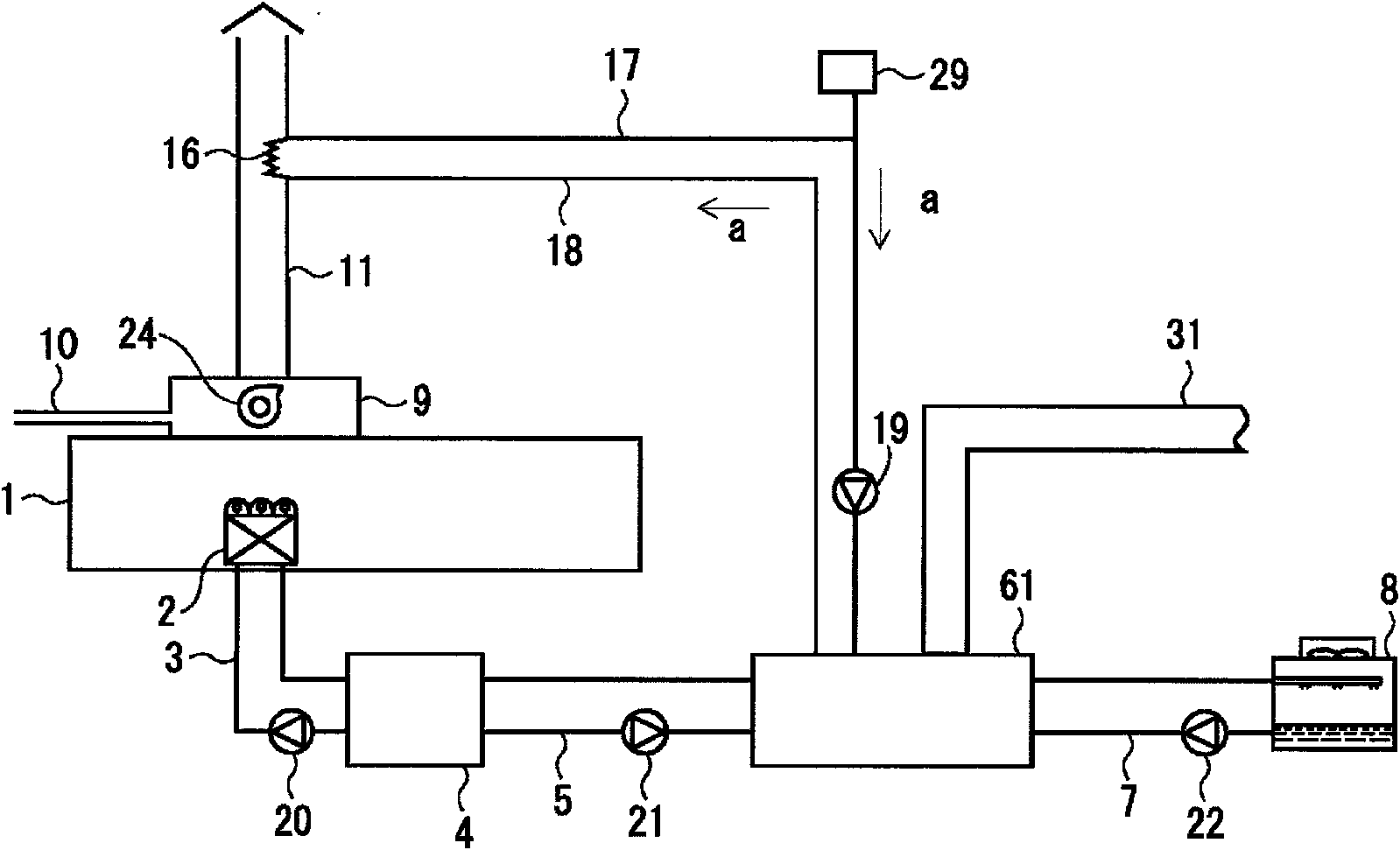

[0052] The waste heat recovery system of the second specific embodiment shown in the figure is as figure 2 shown. In the same configuration as the waste heat recovery system of the first embodiment, the same reference numerals are used, and descriptions thereof are omitted.

[0053] The difference between the second embodiment and the first embodiment is that a second heat exchanger 16 is provided in the middle of the chimney 11 , and high-temperature water circulation pipes 17 and 18 are connected to the second heat exchanger 16 . The high-temperature water circulation pipes 17 and 18 are connected to an absorption refrigerator 61 . A circulation pump 19 is provided in the middle of the high-temperature water circulation pipe 17 , and high-temperature water circulates between the absorption refrigerator 61 and the second heat exchanger 16 . The high temperature water circulation pipe 17 is provided with an expansion tank 29 to absorb the increase in the volume of the high ...

Embodiment 3

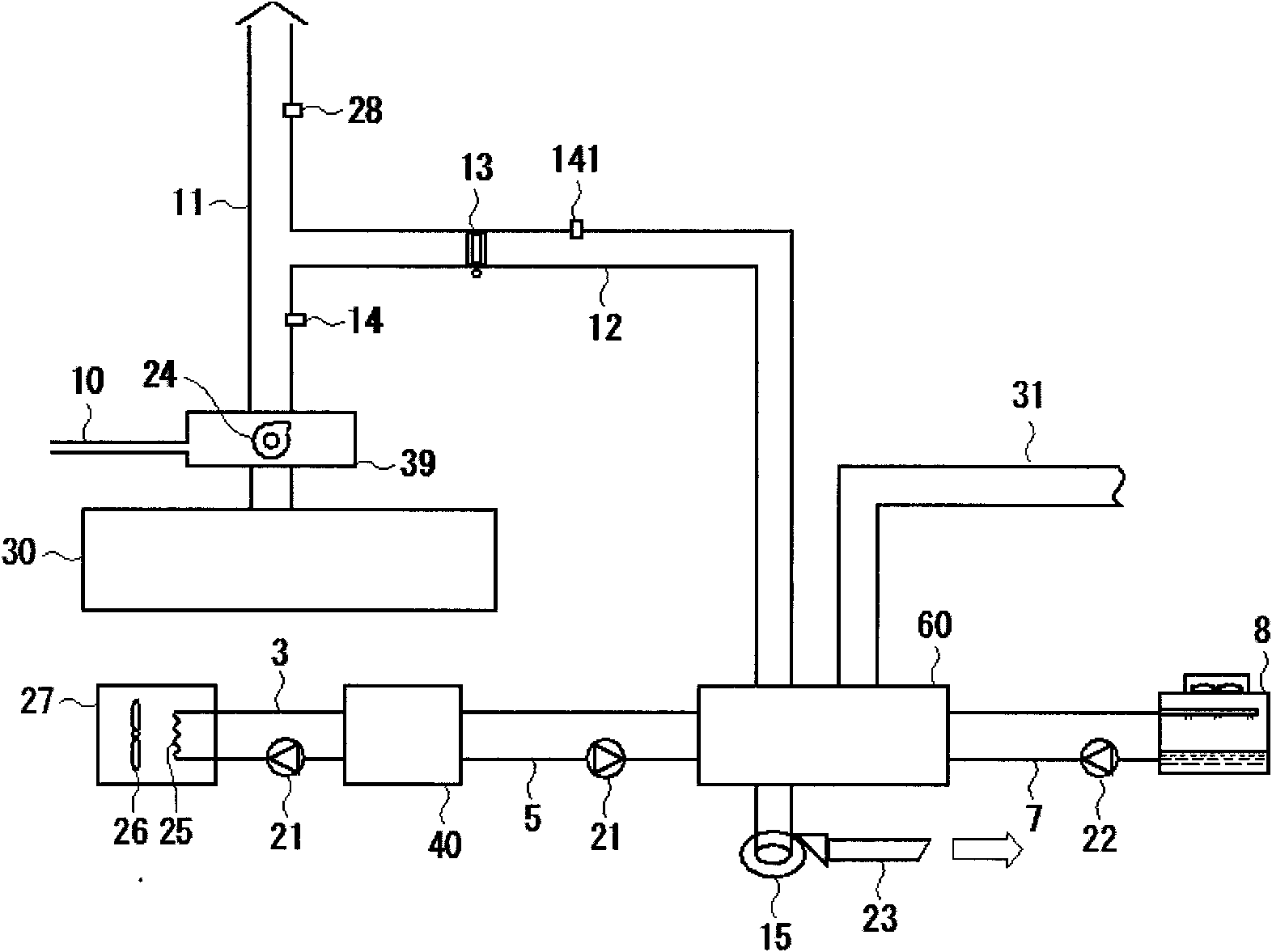

[0061] The waste heat recovery system of embodiment three such as image 3 shown. The same reference numerals are used for the same components as those in the waste heat recovery systems of the first and second embodiments, and the description thereof will be omitted. In this specific embodiment, the equipment that generates VOC is the gravure printing machine 30 . The VOC-containing gas generated by the ink drying function of drying the printed matter of the gravure printing machine 30 is combusted and pyrolyzed by the combustion-type or regenerative combustion-type VOC treatment device 39 . The exhaust gas discharged from the VOC treatment device 39 passes through the chimney 11 and is discharged to the outside air.

[0062] The chimney 11 is connected with one end of an air duct 12 as an exhaust gas duct in the middle. The other end of the air pipe 12 is connected to an exhaust gas absorption type cold and hot water generator 60 . The exhaust gas absorption type cold an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com