Concrete permeability resistance measuring system based on high-frequency alternating current

A high-frequency alternating current and anti-permeability technology, which is applied in the direction of measuring devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problems that affect the test efficiency and accuracy, do not form a unified, limit the application and promotion, etc. Achieve the effects of easy function expansion, large load capacity and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

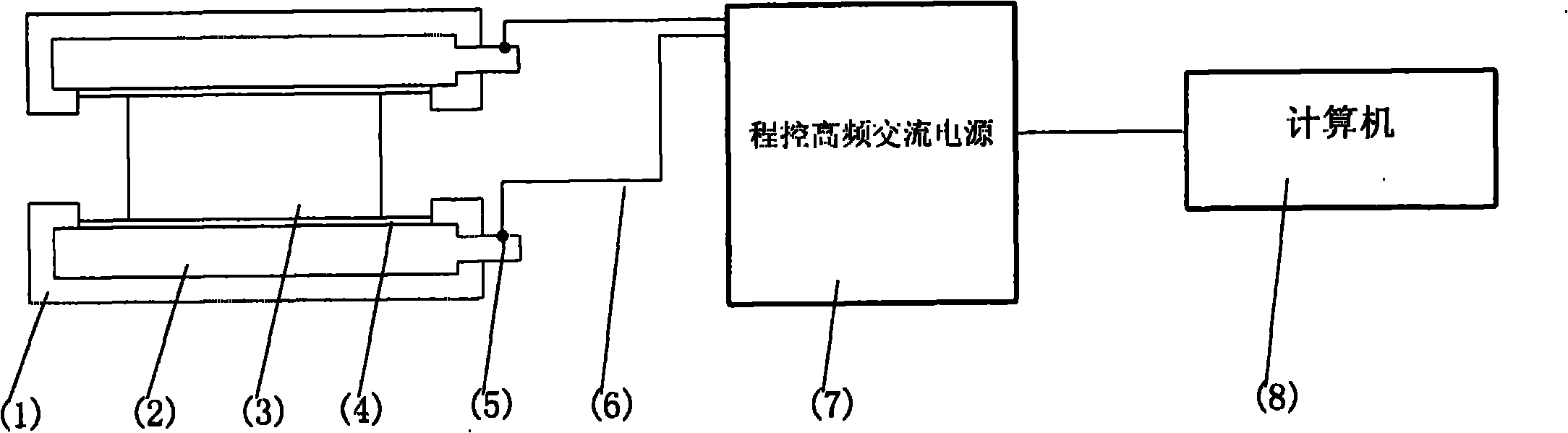

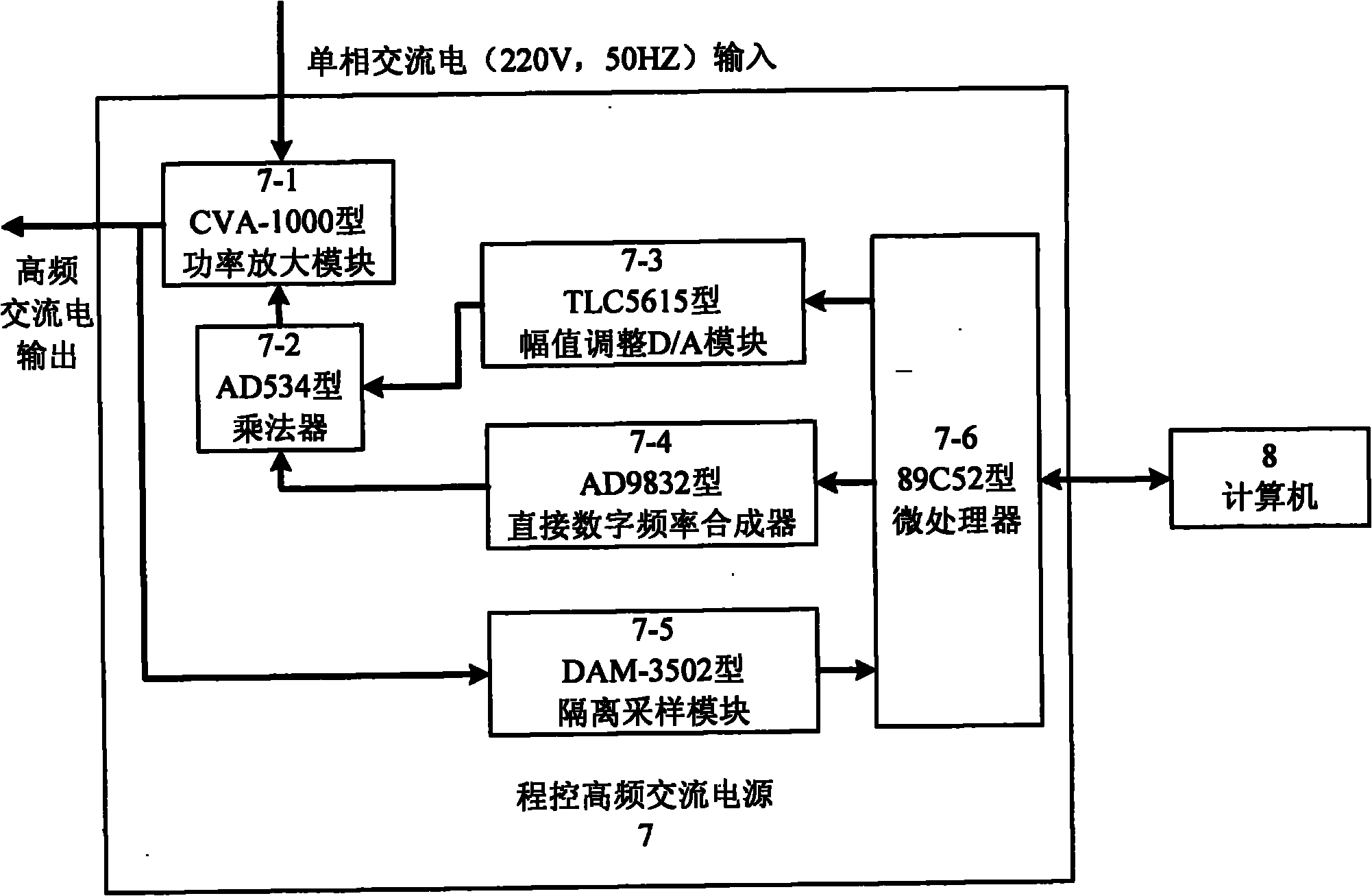

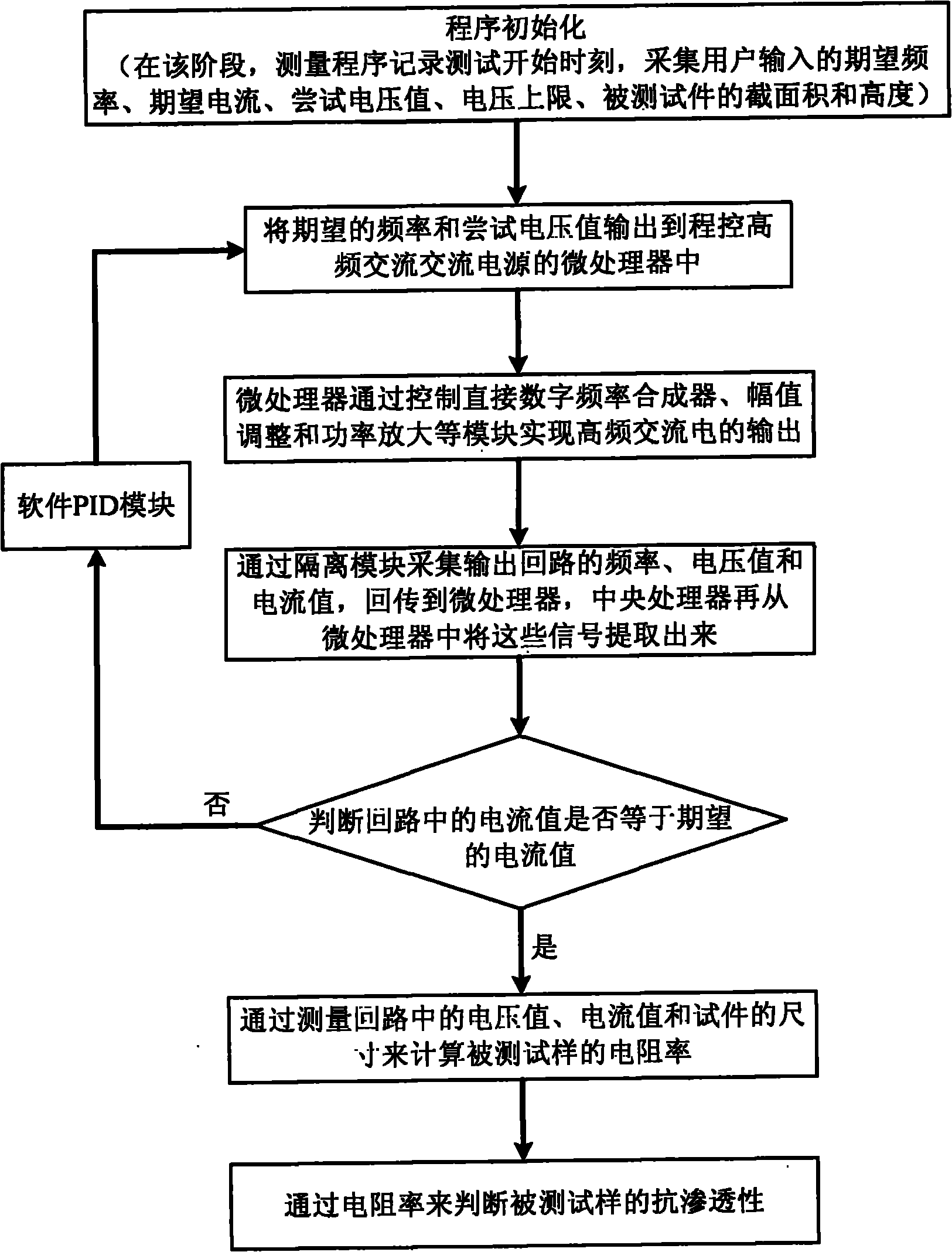

[0035] The structure of the invented high-frequency AC concrete permeability measurement system is as attached figure 1 As shown, the epoxy resin insulation layer 1 of the fixture to be tested; the copper electrode 2; the concrete sample 3 to be tested; the sponge conductive layer 4 between the electrode and the sample; the contact point 5 between the electrode and the wire; the electrode to the program control High-frequency AC power supply wire 6; Programmable high-frequency AC power supply 7; Computer 8.

[0036] Compared with the above-mentioned DC-based electromigration method, the present invention has the following advantages: (1) AC power is used in the test process, which avoids the influence of electrode polarization on the test results; (2) The programmable AC power supply has a high load capacity, The output voltage can reach 600V, the current can reach 4.0A, and the frequency can reach 1000HZ; (3) The PID module in the control program is controlled by intelligent feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com