Device and method for treating obnoxious gas and industrial VOCs

A malodorous gas, industrial technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of low removal rate of single low-temperature plasma technology, difficult adsorption and regeneration of single activated carbon, secondary pollution, etc. The effect of avoiding electrode corrosion problems, prolonging residence time and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

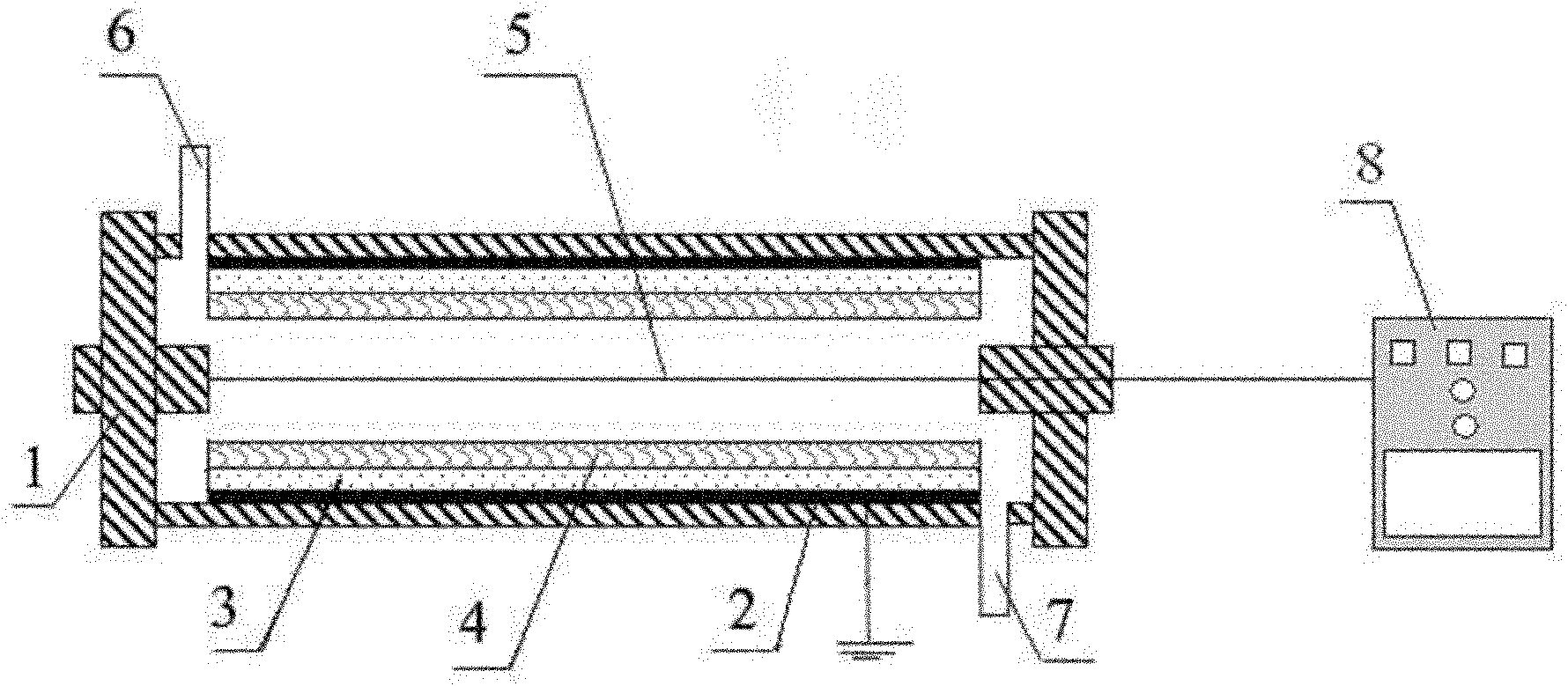

[0021] Such as figure 1 As shown, a device for controlling malodorous gas and industrial VCDs comprises a cylindrical insulating shell 1 with an inner diameter of 50 mm and a length of 200 mm. The insulating shell 1 is made of polymethyl methacrylate, and the two end faces are closed. Air inlets 6 and air outlets 7 are respectively provided at both ends of the surface. An electrode 5 made of sintered metal (Northwest Institute of Nonferrous Metals) is installed in the central axis of the cavity of the insulating shell, with an effective diameter of 0.5mm. The electrode has a 3D network porous structure, and different pore size layers form a pore size gradient. The pore size is mainly mesopores (2-50nm) and macropores (>50nm), and contains a large number of connected or semi-connected pores inside, with a porosity of 80. ~90%, the transition metal catalyst is loaded on the electrode 5, and one or more of Mn, Cu, Fe, Pb, V, Ni, Co and Ti can be selected.

[0022] The outside o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com