Kieselguhr adsorption sustained-release control functional material and production method

A technology of functional materials and production methods, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of high porosity and achieve the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The raw materials for preparing the diatomite adsorption slow-release control functional material are as follows: 55-65 kg of 500-mesh diatomite powder; 0.5-1.5 kg of 1250-mesh tourmaline powder or nano titanium dioxide; 38-42 kg of 325-mesh attapulgite powder.

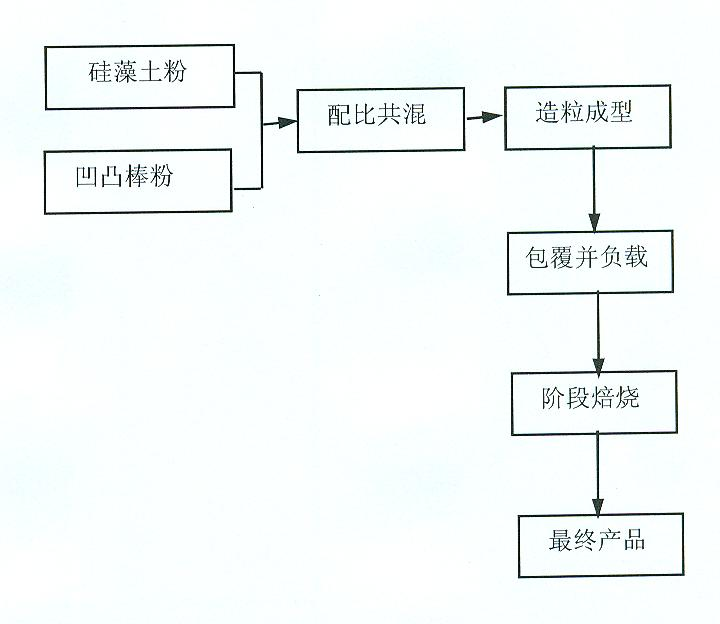

[0014] See figure 1 , the production method is as follows: First, the above-mentioned 500-mesh diatomite powder and a quarter of the 325-mesh attapulgite powder are stirred and mixed, and rolled into a spherical shape by a granulator. The granulation adopts the existing process, that is, rolling granulation Spray a mist liquid adhesive (aqueous solution containing 0.05% CMC); coat the remaining three-quarters of the attapulgite powder on the spherical surface for the first time, and at the same time coat 1250 mesh tourmaline powder or nano-titanium dioxide for the second time; then Drying is carried out by drying equipment at a drying temperature of 100° C. for 2 hours; finally, roasting is carried out by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com