Catalyst for use in preparation of piperidine and piperidine derivatives

A technology of catalysts and derivatives, applied in the field of catalysts for the hydrogenation conversion of pyridine and pyridine derivatives into piperidine and piperidine derivatives, which can solve the problem of high price of raw material pyridine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

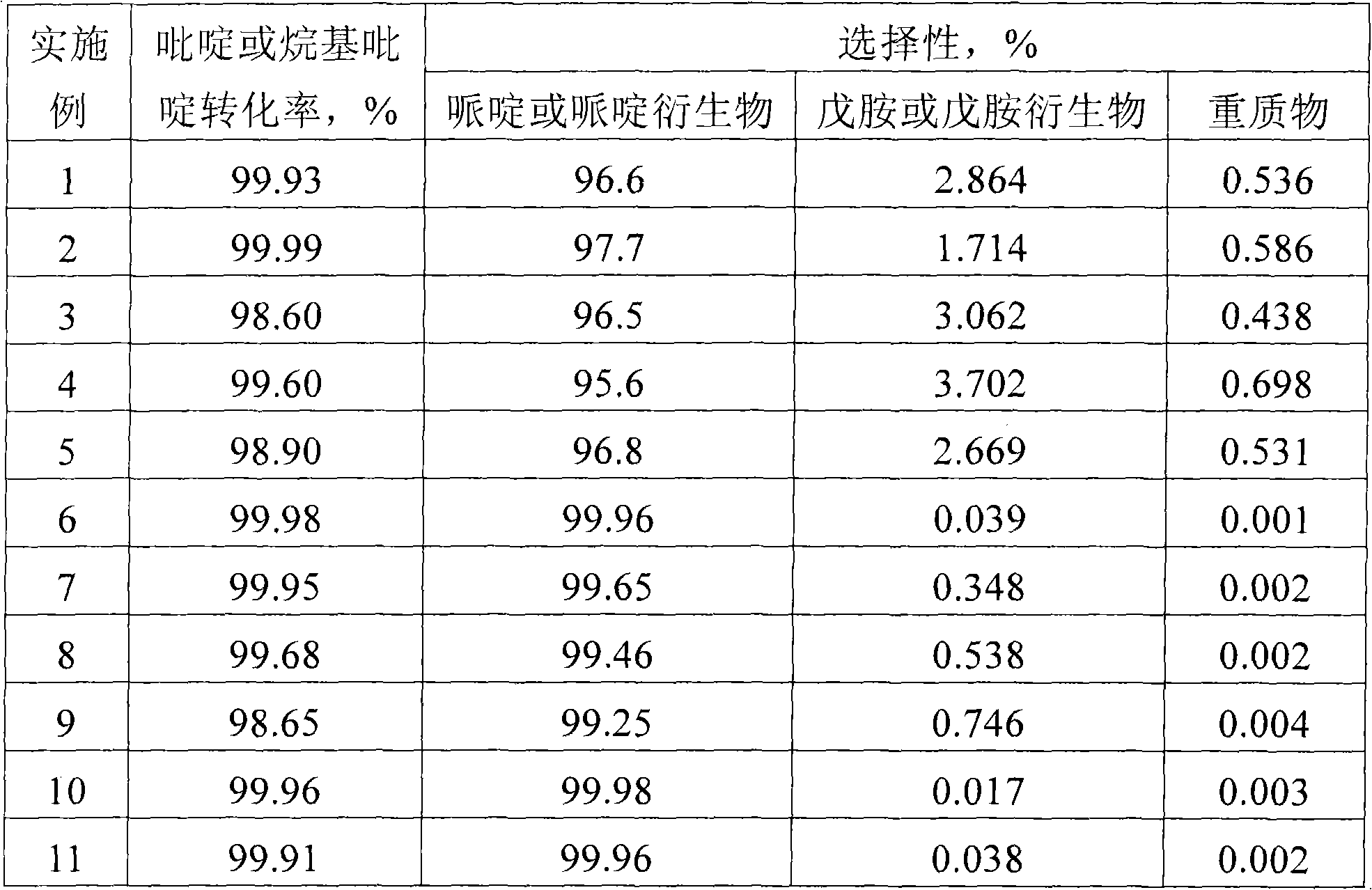

Examples

Embodiment 1

[0024] The catalyst of embodiment 1 is 15%Ni-0.1%Ru / Al 2 o 3 . Weigh 20 grams of Al 2 o 3 (20-40 mesh), roasted at 500°C for 6 hours before use, and configure 22ml containing 10.999 grams of Ni(NO 3 ) 2 and 0.041 g RuCl 3 aqueous solution, with half of this aqueous solution impregnated with the above Al 2 o 3 The carrier is air-dried, oven-dried at 120°C for 4 hours (h), and baked at 500°C for 5 hours. The other half of the above aqueous solution was impregnated with the above Ni, and Ru metal-loaded Al 2 o 3 The carrier is then air-dried, oven-dried at 120°C for 4 hours, and baked at 500°C for 5 hours. Before use, in 300°C hydrogen (atmospheric pressure, 2500h -1 ) reduction activation for 5 hours.

Embodiment 2

[0026] Catalyst 15%Ni-0.3%Pd-0.03%Ru / Al of embodiment 2 2 o 3 . In addition to the configuration of 22ml containing 11.157 grams of Ni (NO 3 ) 2 , 0.119 g PdCl 2 and 0.0147 g RuCl 3 Except aqueous solution, all the other preparation steps are identical with embodiment 1.

Embodiment 3

[0028] Catalyst 15%Ni-2%Co-10%TiO of Example 3 2 / Al 2 o 3 . In addition to configuring 22ml containing 10.612 grams of Ni (NO 3 ) 2 , 1.411 g Co(NO 3 ) 2 and 8.088 g Ti(OC 3 h 7 ) 4 Except aqueous solution, all the other preparation steps are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com