Process for welding vacuum freeze dryer plate layer

A vacuum freeze-drying and welding process technology, applied in welding equipment, manufacturing tools, resistance welding equipment, etc., can solve the problems of limited fatigue strength, difficult detection, complex process, etc. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

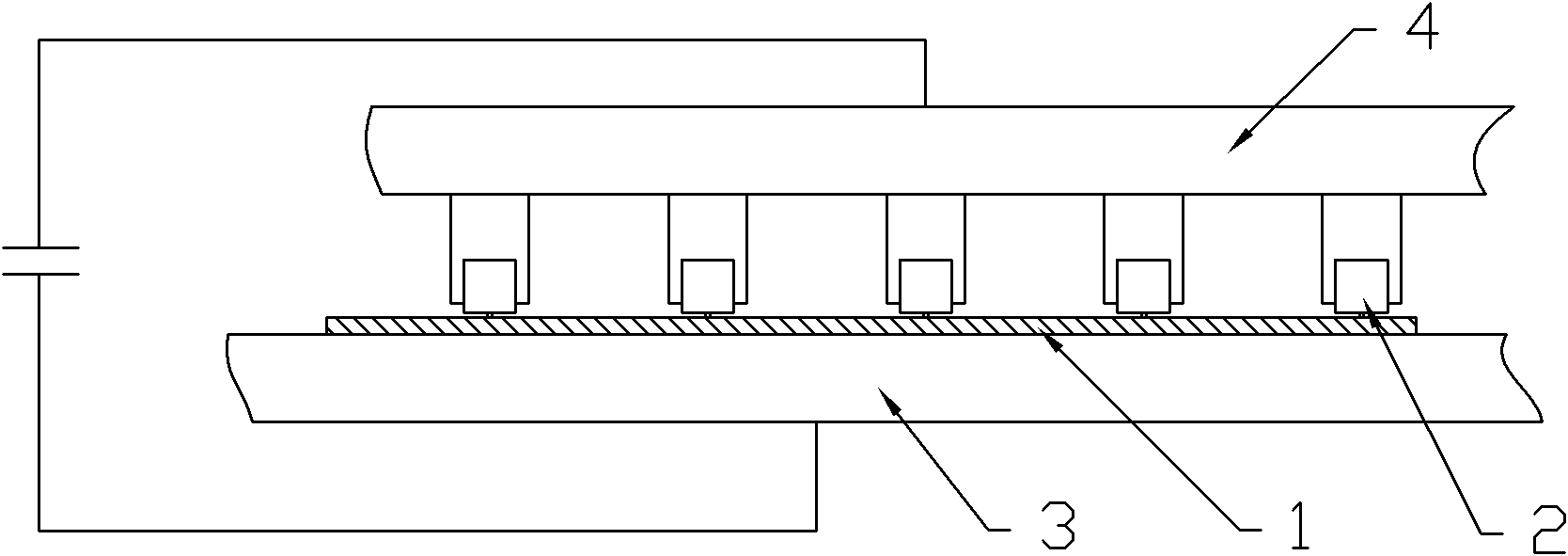

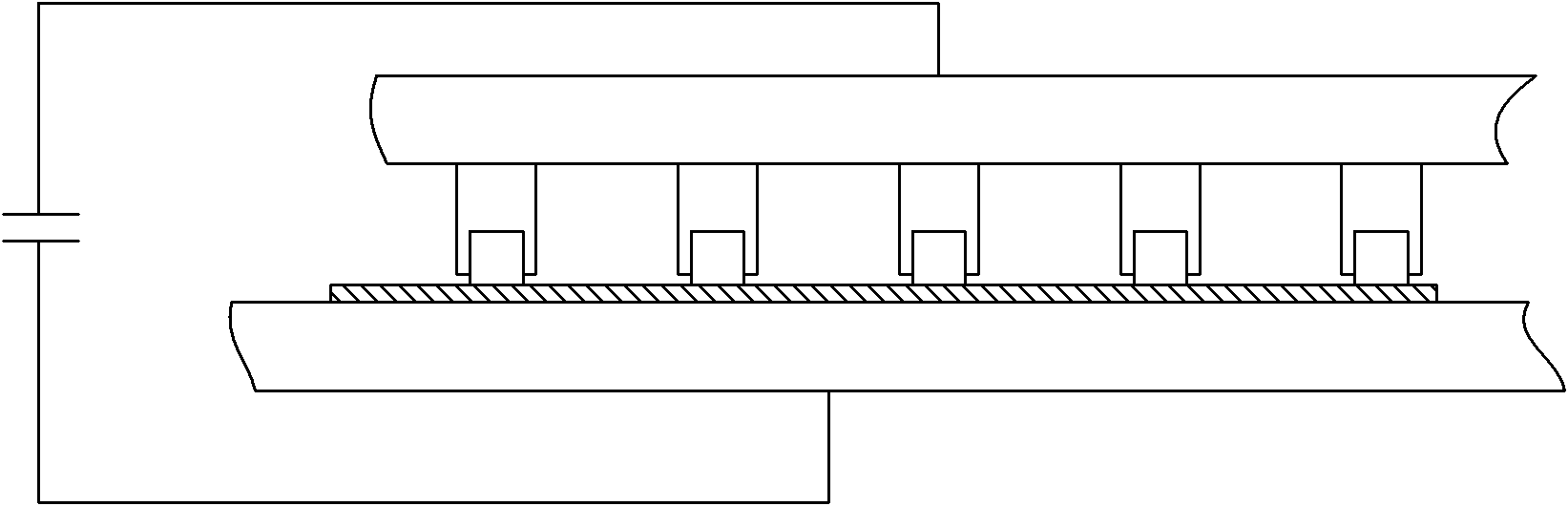

[0024] Refer to attached Figure 1~2 :

[0025] Place the upper panel 1 horizontally on the lower electrode plate 3 that has been flattened by energy storage resistance welding, and then lower the upper electrode plate 4 after installing the support column 2, press the support column 2 vertically on the upper panel 1, and press the energy storage capacitor through the welding transformer. The standard parameters of the design are discharged once, and the bumps under the support column 2 are rapidly melted during welding, and at the same time, the upper electrode is pressed down rapidly, and multiple sets of support columns 2 are welded side by side and parallel to the upper surface of the upper panel 1 at one time, with the lower electrode as the end. The plane is a horizontal planar electrode. The number of supporting columns is determined according to the size of the vacuum freeze dryer plate and arranged evenly.

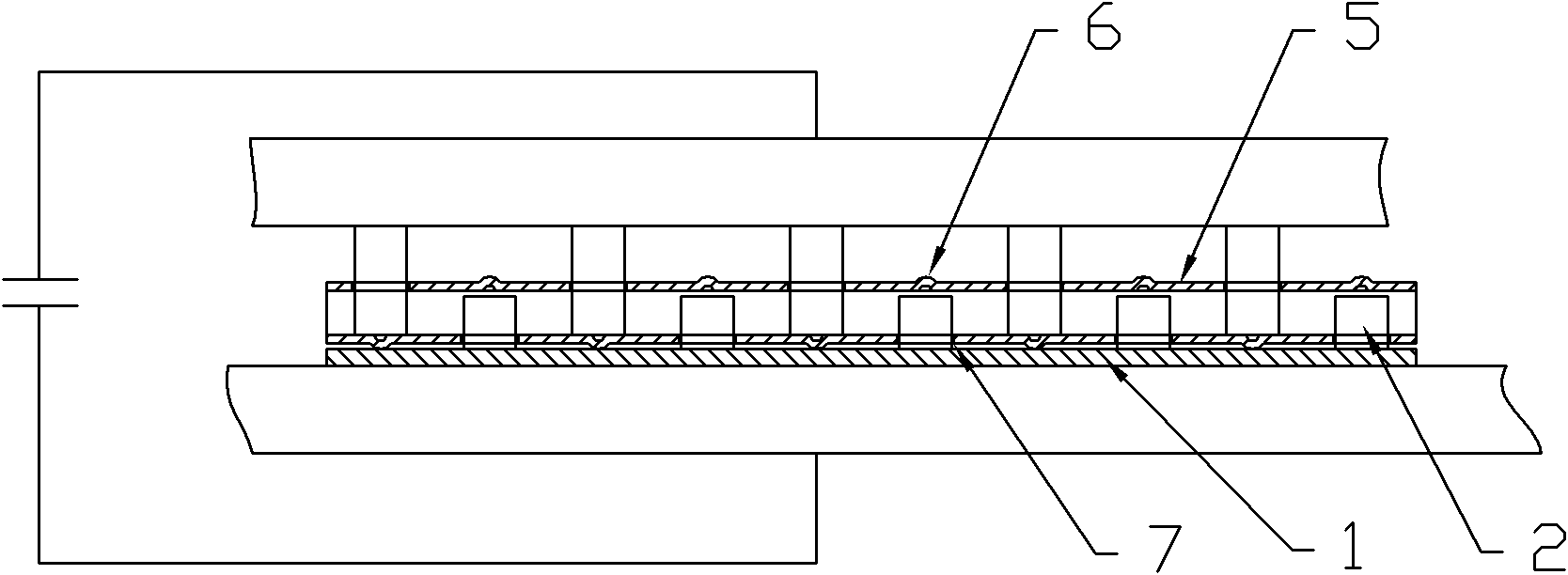

[0026] Refer to attached Figure 3-4 :

[0027] The space...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com