Air-exhausting flexible packaging bag for frozen vegetables and preparation method thereof

A technology of flexible packaging bags and packaging bags, which is applied in the field of ventilated frozen vegetable flexible packaging bags and its preparation, can solve the problems of high cost, limited film materials, poor pollution resistance, etc., and achieve low cost, simple operation, and long shelf life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

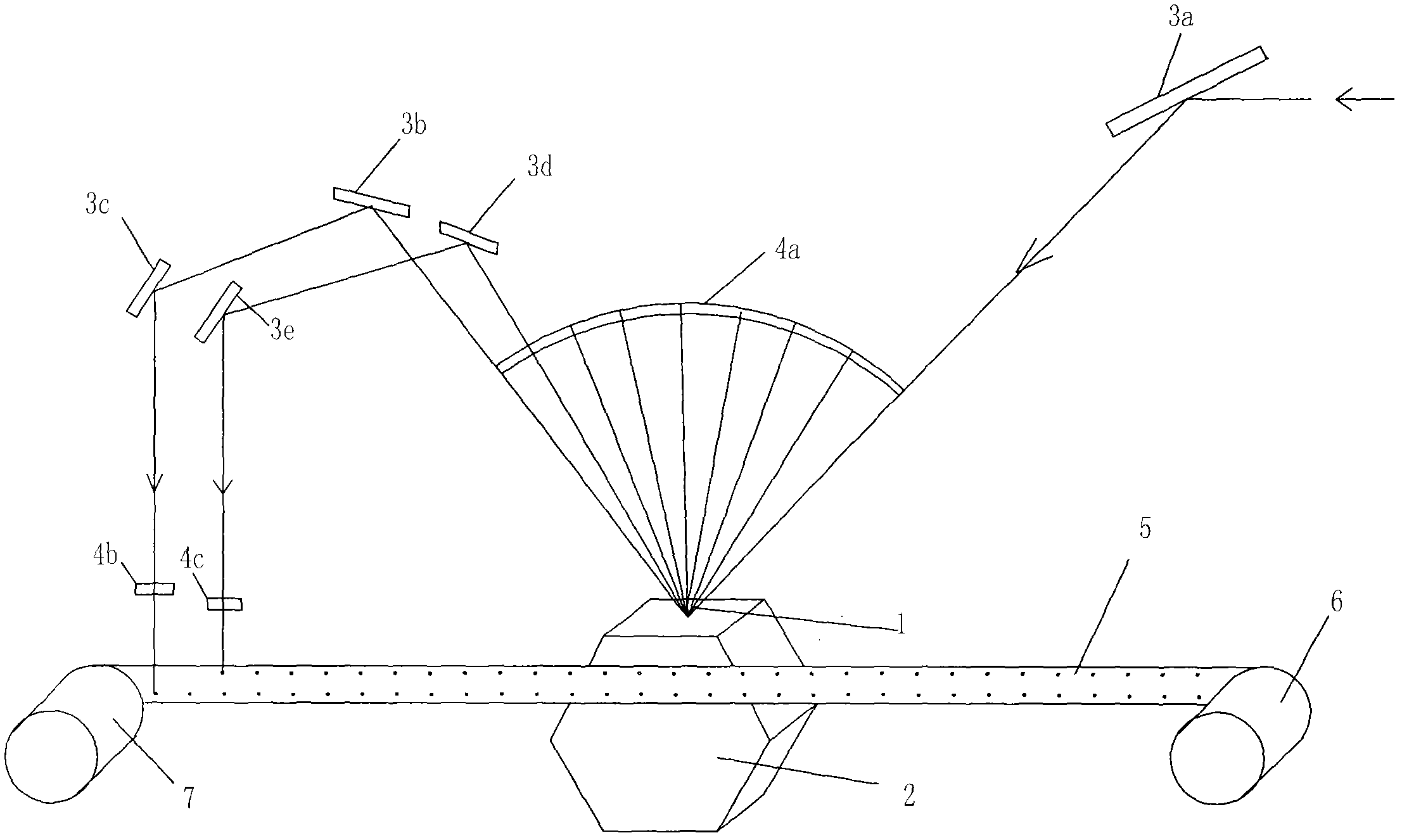

Method used

Image

Examples

Embodiment 1

[0046] In this embodiment, PET / PE transparent composite film is selected as the material of the ventilated frozen vegetable flexible packaging bag of the present invention. The outermost layer of this film is PET (polyethylene terephthalate), the innermost layer is PE (polyethylene), and the middle is adhesive, with a total thickness of 54 μm.

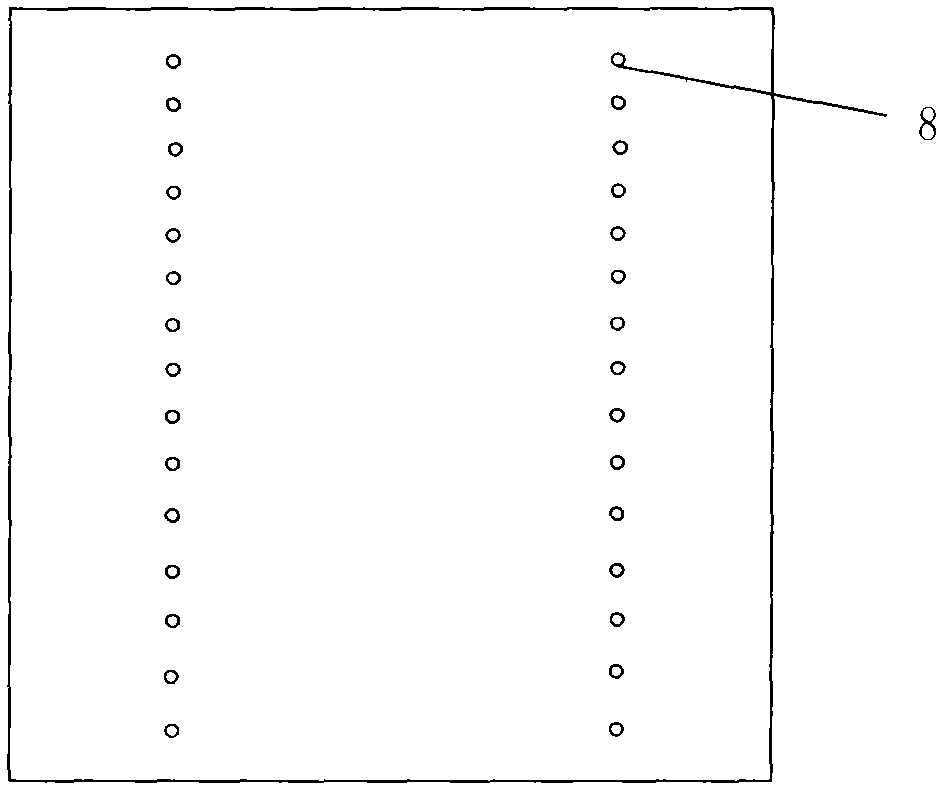

[0047] According to the above-mentioned preparation method, in step 2, the diameter of the vent hole is set to 100μm, the feeding speed of the film feeding device and the speed of the rotating prism lens are set to 100m / min, and the number of punching rows is set to 2 rows, The prepared flexible packaging film with 2 rows of air holes is as follows: figure 2 As shown, the diameter of the air holes 8 is 200 μm, and the hole spacing is 10 mm.

[0048] After the vent hole is finished, the film is cut and processed into a bag body of 200mm×140mm.

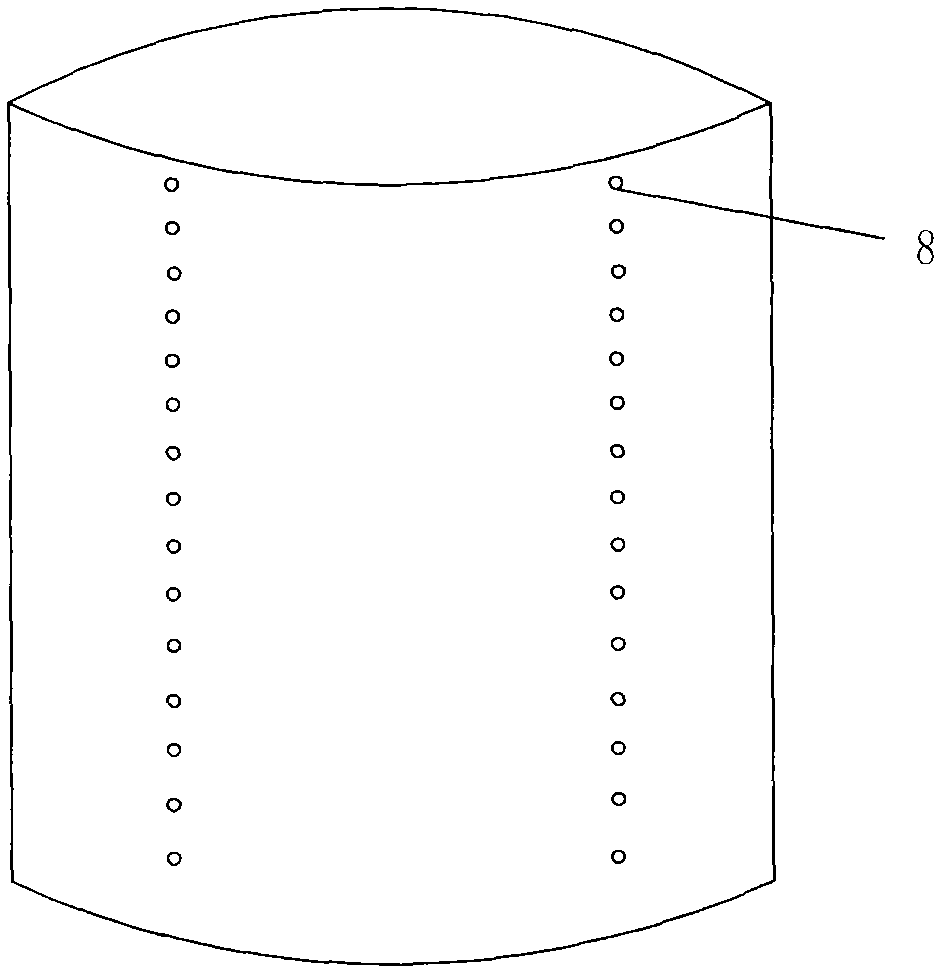

[0049] image 3 The venting flexible packaging bag produced by the flexible packaging fi...

Embodiment 2

[0056] In this embodiment, BOPP / PE transparent composite film is selected as the material of the vented frozen vegetable flexible packaging bag of the present invention. The outermost layer of this film is BOPP (biaxially oriented polypropylene film), the innermost layer is PE (polyethylene), and the middle is adhesive, with a total thickness of 62 μm.

[0057] According to the above-mentioned preparation method, in step 2, the diameter of the vent hole is set to 150μm, the feeding speed of the film feeding device and the speed of the rotating prism lens are set to 90m / min, and the number of punching rows is set to 2 rows, The diameter of the air holes is 150 μm, and the hole spacing is 7 mm.

[0058] After the vent hole is finished, the film is cut and processed into a bag body of 220mm×150mm.

[0059] The test results of the vented flexible packaging bag are as follows:

[0060] 1. Store peppers, beans, and cucumbers in the air-vented packaging bag for 6-8 months at -18°C....

Embodiment 3

[0065] In this embodiment, PE co-extruded transparent film is selected as the material of the ventilated frozen vegetable flexible packaging bag of the present invention. This kind of co-extrusion film structure is LDPE (low density polyethylene), PP (polypropylene), LDPE (low density polyethylene) from outside to inside, the thickness ratio between each layer is 1:3:1, and the total thickness is 65μm .

[0066] According to the above-mentioned preparation method, in step 2, the diameter of the vent hole is set to 100μm, the feeding speed of the film feeding device and the speed of the rotating prism lens are set to 90m / min, and the number of punching rows is set to 2 rows, The diameter of the air holes is 100 μm, and the hole spacing is 5 mm.

[0067] After the ventilation holes are finished, the film is cut and processed into bags of 240mm×160mm.

[0068] The test results of the vented flexible packaging bag are as follows:

[0069] 1. Store peppers, beans, and cucumbers ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com