Prestressed concrete pipe grouting agent

A technology of concrete and grouting agent, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the threats to the safety life and service reliability of prestressed structures, the loss of cement passivation protection in space, and the corrosion of steel bars Partial section defects, etc., to reduce the brittleness coefficient of the slurry, improve the interface adhesion and crack resistance, and improve the strength of the slurry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the present invention are given below to describe the technical solution of the present invention in detail.

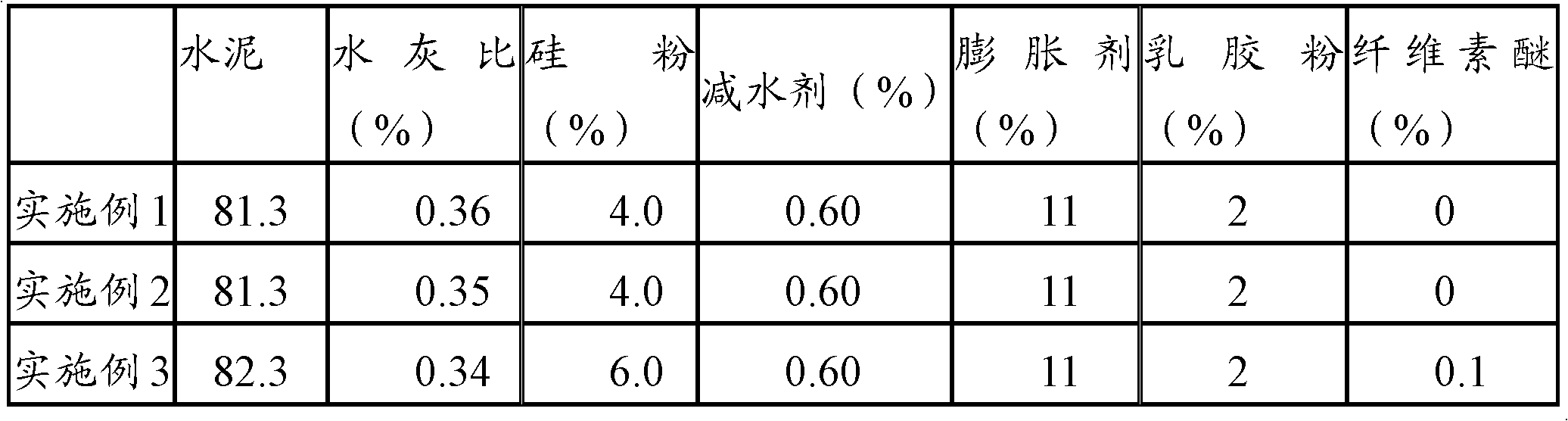

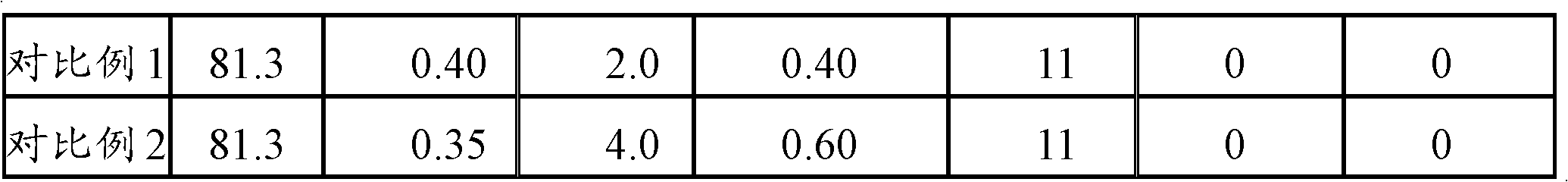

[0030] Table 1 shows the specific components and proportions of Examples 1-3 and Comparative Examples 1 and 2.

[0031] Table 1

[0032]

[0033]

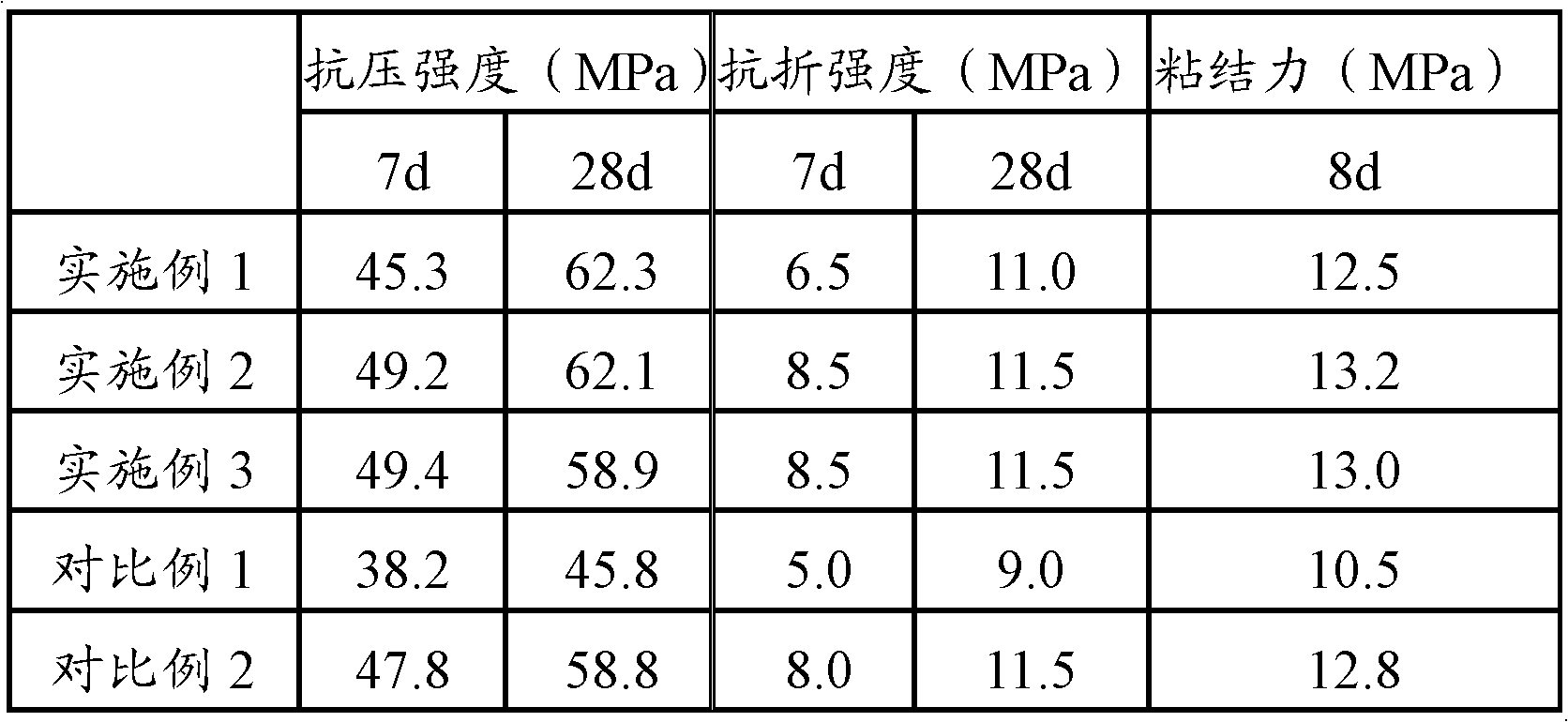

[0034] The test results of fluidity, bleeding rate and filling degree are shown in Table 2, and the test results of mechanical properties of the specimen are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com